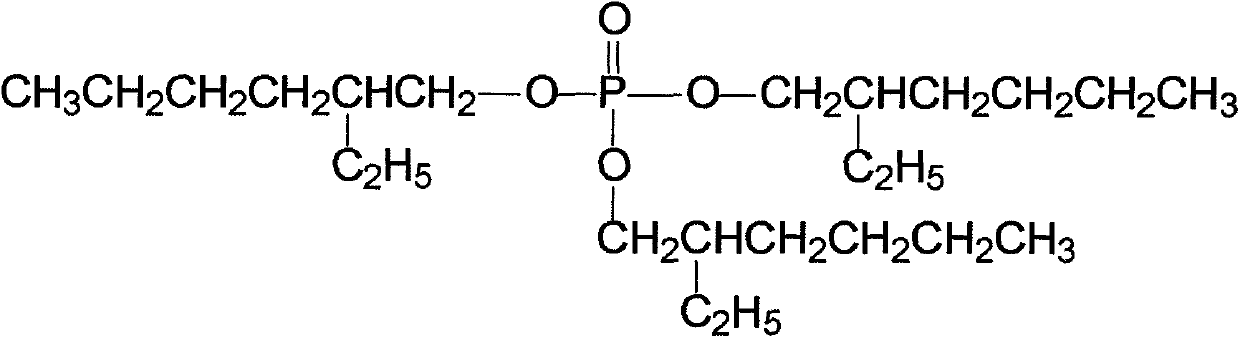

Production method of trioctyl phosphate

A technology of trioctyl phosphate and a production method, applied in the field of chemical material production, can solve problems such as unrefined products, unfavorable production efficiency, air pollution, etc., and achieve the effects of shortening esterification time, improving production efficiency, and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] First add measured isooctyl alcohol into the mixing tank, cool it down to below -15°C with frozen brine, then add measured phosphorus oxychloride in batches under vacuum conditions, the material ratio is phosphorus oxychloride to octanol moles The ratio is 1:3.10. Then add metered catalyst, the catalyst consumption is 0.5% of the mass of phosphorus oxychloride. Control the adding speed of phosphorus oxychloride, so as to control the mixing temperature not higher than 20°C, and reduce the occurrence of side reactions.

[0045] Under the vacuum condition of -0.097MPa, the above-mentioned mixed materials are slowly heated up. In the early stage, the temperature rise rate is controlled at about 15-20°C / h, so that the hydrogen chloride gas generated by the reaction can be discharged in time to reduce the occurrence of side reactions. After 3 hours of reaction, when the material in the reactor reaches 80°C, speed up the temperature rise rate and control it at 30°C. ℃ / h to s...

Embodiment 2

[0051] The material proportioning of embodiment 1 is phosphorus oxychloride and octanol molar ratio is 1: 3.15, and the mol ratio of lye and phosphorus oxychloride is 1: 15, under the vacuum condition of-0.097MPa, above-mentioned mixing Good materials slowly heat up. In the early stage, the heating rate is controlled at about 15-20°C / h, so that the hydrogen chloride gas produced by the reaction can be discharged in time to reduce the occurrence of side reactions. After 3 hours of reaction, when the material in the reactor reaches 90°C, speed up the heating rate and control it at 30°C. ℃ / h to speed up the reaction. Because the amount of octanol decreases in the later stage of the reaction, the reaction rate is relatively slow. In order to improve the product yield, when the reaction temperature reaches 110° C., add 10% of the above-mentioned octanol amount to the reaction system and react for 1 hour. When the temperature rises to 150° C., the reaction ends. The reaction time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com