Dibutyl phthalate production process capable of preventing crystallization in esterification kettle

A dibutyl phthalate and production process technology, applied in the field of dibutyl phthalate production process, can solve the problems of high steam energy consumption, prolonging the esterification time, affecting the heating efficiency of the esterification tank, etc., achieving Improve production efficiency, shorten energy saving, and shorten the effect of esterification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

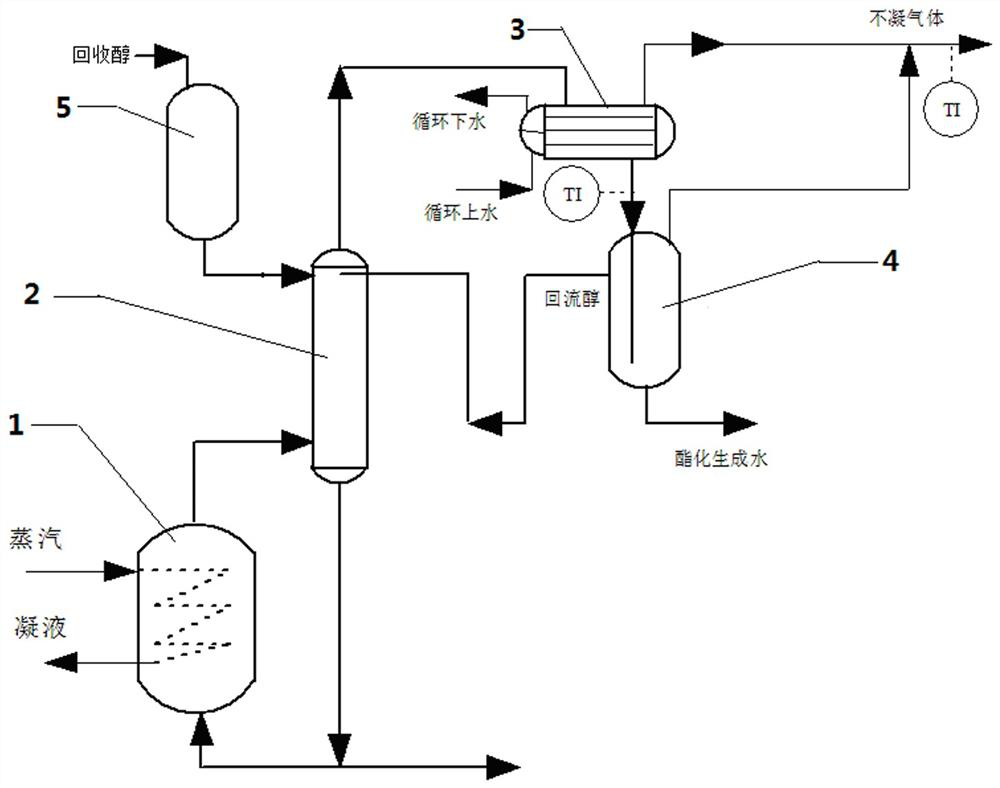

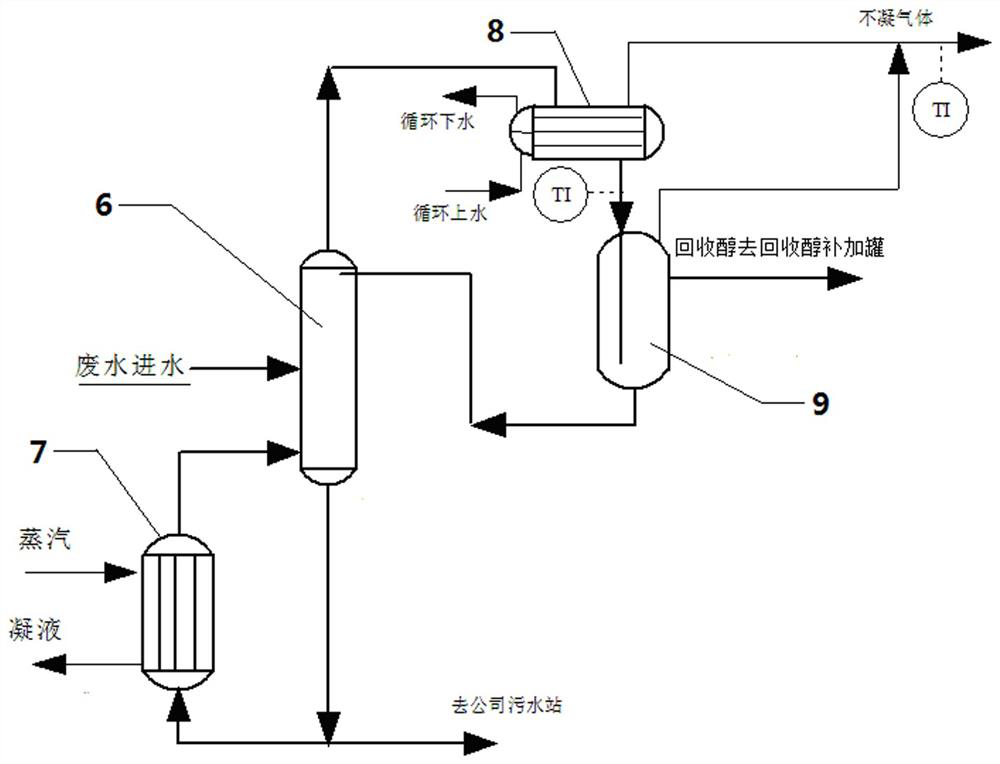

[0020] The present invention relates to a kind of dibutyl phthalate production technology that prevents crystallization in the esterification still, such as figure 1 , figure 2 As shown, n-butanol, naphthalene phthalic anhydride, and concentrated sulfuric acid are sequentially added to the esterification kettle 1 to heat up the reaction, and the temperature of the esterification kettle 1 is heated by an inner coil. for 6h. The steam evaporated from the top of the esterification kettle 1 enters the esterification tower 2 and then condenses through the condenser (1) 3, then enters the alcohol-water separation tank (1) 4 for alcohol-water separation, and the separated reflux alcohol flows from the esterification tower 2 It is added at the top of the tower, and flows into the esterification kettle 1 after reverse contact with the steam steamed from the esterification kettle 1; after the esterification reaction is completed, the product is introduced into the neutralization kettl...

Embodiment 2

[0023] The present invention relates to a kind of dibutyl phthalate production technology that prevents crystallization in the esterification still, such as figure 1 , figure 2 As shown, n-butanol, naphthalene phthalic anhydride, and concentrated sulfuric acid are sequentially added to the esterification kettle 1 to heat up the reaction, and the temperature of the esterification kettle 1 is heated by an inner coil. It is 5.5h. The steam evaporated from the top of the esterification kettle 1 enters the esterification tower 2 and then condenses through the condenser (1) 3, then enters the alcohol-water separation tank (1) 4 for alcohol-water separation, and the separated reflux alcohol flows from the esterification tower 2 It is added at the top of the tower, and flows into the esterification kettle 1 after reverse contact with the steam steamed from the esterification kettle 1; after the esterification reaction is completed, the product is introduced into the neutralization k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com