Esterification catalyst, esterification catalysis system and method for preparation of esterification catalyst and esterification catalyst reaction

An esterification catalytic system and esterification catalyst technology are applied in the directions of physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., which can solve the problems of high price, pollute the environment, and the owners cannot afford it, and reduce production costs. , the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] The present invention adopts the following technical solutions: an esterification catalyst, including silica gel and iron, zirconium, titanium, tin, scandium, and sulfuric acid adsorbed on the silica gel; the iron, zirconium, titanium, tin, scandium, and sulfuric acid account for the mass of the silica gel The percentages are: iron 9%-30%, zirconium 0.009%-0.015%, titanium 9%-30%, tin 0.3%-3%, scandium 0.003%-0.009%, sulfuric acid 59%. The silica gel is C-type macroporous silica gel, with an average pore diameter of 8.0-10.0 nm and a specific surface area of 300-400 square meters per gram.

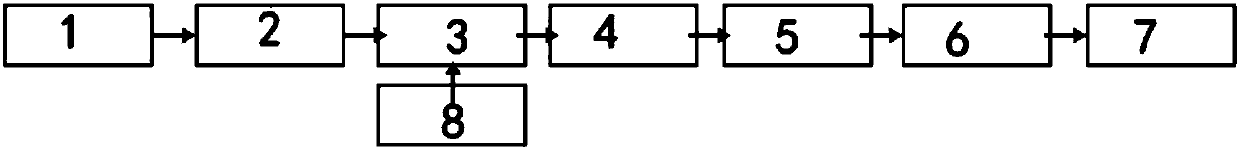

[0016] Such as figure 1 As shown, the esterification catalytic system for preparing esterification catalyst includes raw liquid pool 1, chemical filter tank 2, adsorption zone 3, drying and dehydration zone 4, roasting furnace 5, esterification reaction tank 6, deacidification oil tank 7, silica gel 8; The raw liquid pool 1, chemical filter 2, adsorption area 3, drying and dehydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com