Preparation system and preparation method of biodegradable copolyester and copolyester thereof

A preparation system and copolyester technology are applied in the field of preparation method and copolyester, biodegradable copolyester preparation system, and can solve the problem of limited processing and use of biodegradable copolyester and low intrinsic viscosity of sliced products. , the problem of high content of terminal carboxyl groups, to achieve good biodegradable performance, shorten the esterification time, and low content of terminal carboxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

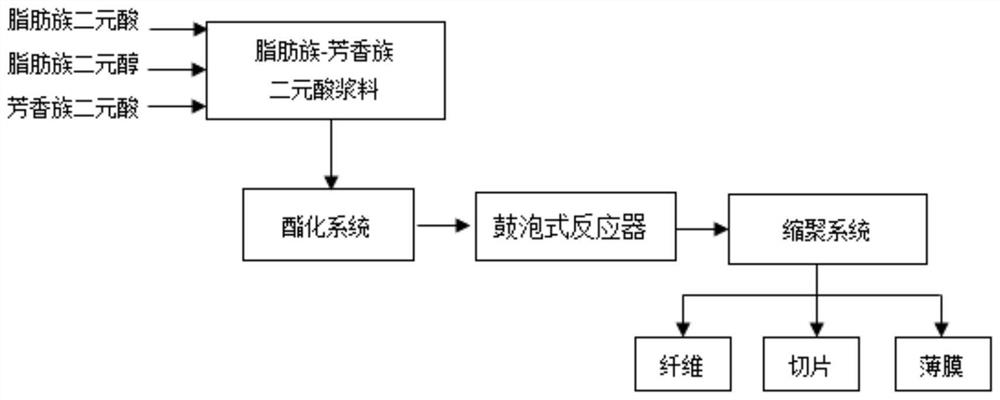

[0061] A preparation system for biodegradable copolyester, comprising: an esterification reactor 20, a bubble reactor 10, a final polycondensation reactor and a liquid-phase thickening reactor connected in sequence.

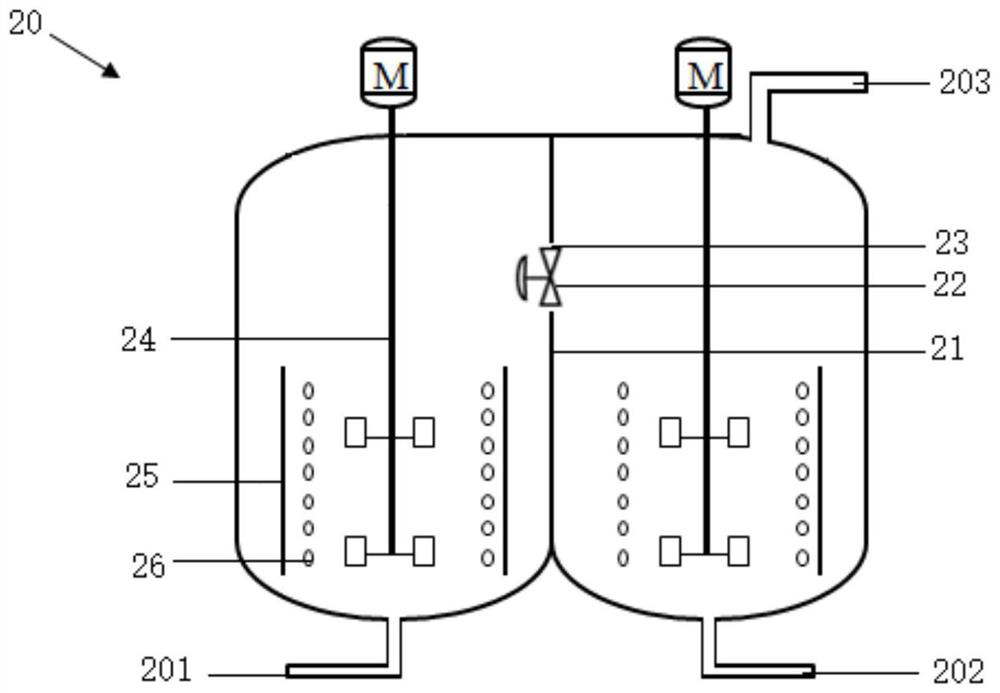

[0062] The esterification reactor 20 is provided with two independent chambers separated by a partition 21, the reactor material inlet 201 of the esterification reactor 20 is arranged at the bottom of the first chamber, and the reactor material outlet 202 is arranged at the second chamber. At the bottom of the chamber, the esterification steam outlet 203 is arranged on the top of the second chamber; each chamber is equipped with an axial flow type agitator, a guide tube 25 and a heating coil 26, and the dividing plate 21 is provided with a The guide hole 23 for material and steam flow controlled by degree regulating valve 22.

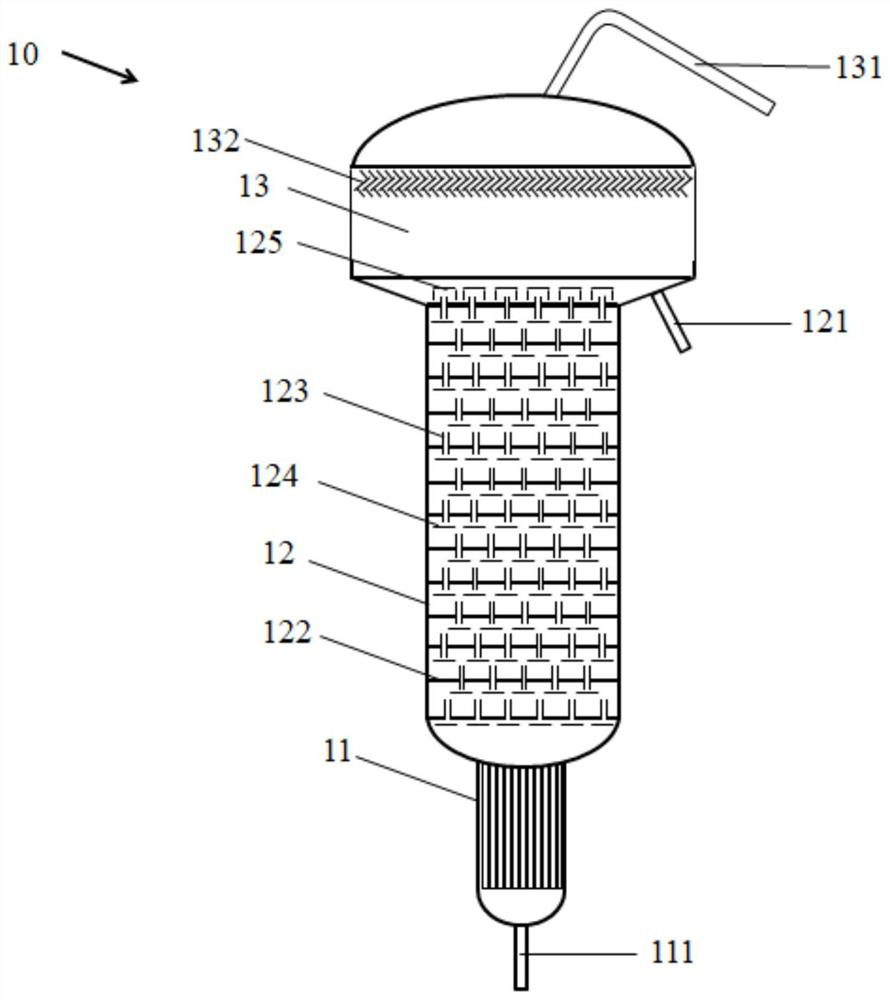

[0063] The bubble reactor 10 includes a preheater 11, a reactor body 12 and a gas-liquid separator 13 arranged in sequence along the flow...

Embodiment 1

[0066] In this example, the steps of the preparation method of the biodegradable copolyester preparation system of the application experiment example are as follows:

[0067]S1, the alkyd molar ratio of succinic acid, terephthalic acid, butanediol and the ternary compound that is 1:0.5:0.2 by the molar ratio of titanium element, aluminum element and phosphorus element as catalyst modulation is 1.3: 1 succinic acid-terephthalic acid slurry. The molar ratio of terephthalic acid to succinic acid is 50:50; the catalyst is made of tetrabutyl titanate, aluminum ethylene glycol, bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite It is prepared by mixing titanium, aluminum and phosphorus in a molar ratio of 1:0.5:0.2 and reacting at 200°C for 5 hours.

[0068] S2, transporting the succinic acid-terephthalic acid slurry to an esterification reactor to prepare a succinic acid-terephthalic acid-butylene glycol copolyester ester having an acid value of 50 mgKOH / g. The reaction tem...

Embodiment 2

[0072] In this example, the steps of the preparation method of the biodegradable copolyester preparation system of the application experiment example are as follows:

[0073] S1, the alkyd molar ratio of adipic acid, terephthalic acid, butanediol and the ternary compound that is 1:0.3:0.1 by the mol ratio of titanium element, aluminum element and phosphorus element as catalyst modulation is 1.4: 1 adipic-terephthalic acid slurry. Wherein the molar ratio of terephthalic acid and adipic acid is 50:50; The catalyst is made of tetrabutyl titanate, aluminum ethylate, three (2,4-di-tert-butylphenyl) phosphite according to titanium element, The molar ratio of aluminum and phosphorus is 1:0.3:0.1 and then reacted at 180°C for 3 hours.

[0074] S2, transporting the adipic acid-terephthalic acid slurry to an esterification reactor to prepare an esterified adipic acid-terephthalic acid-butylene glycol copolyester with an acid value of 30 mgKOH / g. Wherein the reaction temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com