Method for preparing biodiesel by using waste grease split-phase method

A technology of biodiesel and waste oil, applied in biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of high energy consumption, many catalysts, long reaction time, etc., achieve no environmental pollution, reduce esterification time, value-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

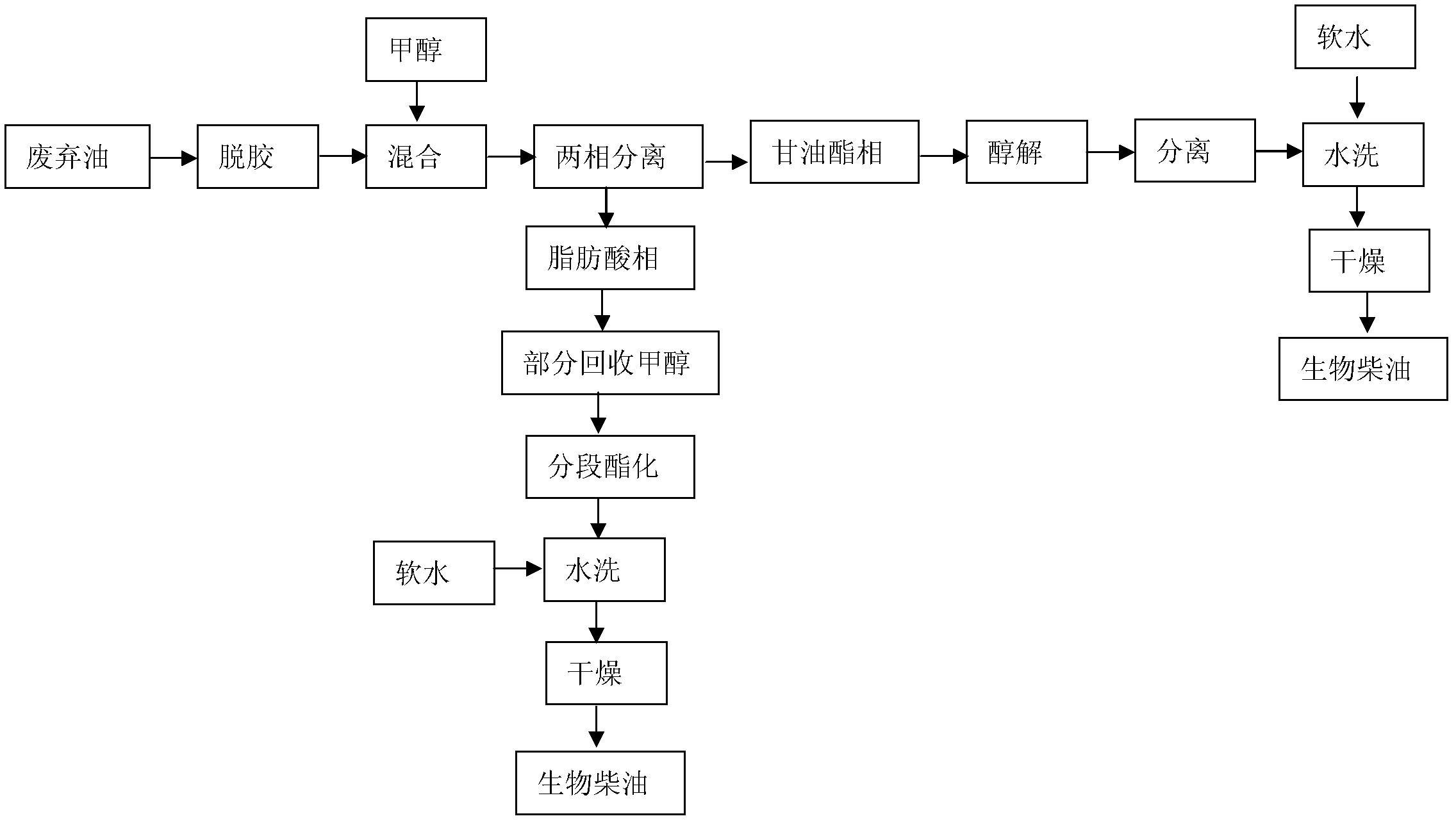

[0028] Phase separation process of waste oil

[0029] Degumming

[0030] see figure 1 Weigh the waste oil (waste oil, AV77) and heat it to 80°C, then add 0.3% concentrated sulfuric acid with a concentration of 98% and stir for 20 minutes, then add 5% of the oil weight and hot salt water with a concentration of 2% and a temperature of about 85°C Continue to stir for 30 minutes, and finally separate the waste water through a centrifuge with a rotating speed of 3000r / min, and dry it for later use.

[0031] Free fatty acid-glyceride two-phase separation

[0032] Mix the weighed degummed waste oil and methanol at a ratio of 1:1.5 (w / w), and stir with a magnetic stirrer for 30 minutes at 30°C, then put it in a separatory funnel and separate the lower layers of glycerol For the ester phase, take a sample to determine the acid value of the glyceride phase. Repeat the above operation according to the acid value, the number of separations is 4-5 times, until the acid value drops to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com