Preparation method and application of aqueous acrylic modified epoxy ester resin

A technology of epoxy ester resin and water-based acrylic, which is applied in the direction of coating, etc., can solve the problems of adhesion, water resistance, film-forming strength and other performance degradation, achieve the optimization of color matching and additive use, improve the degree of water-based, The effect of increasing carboxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

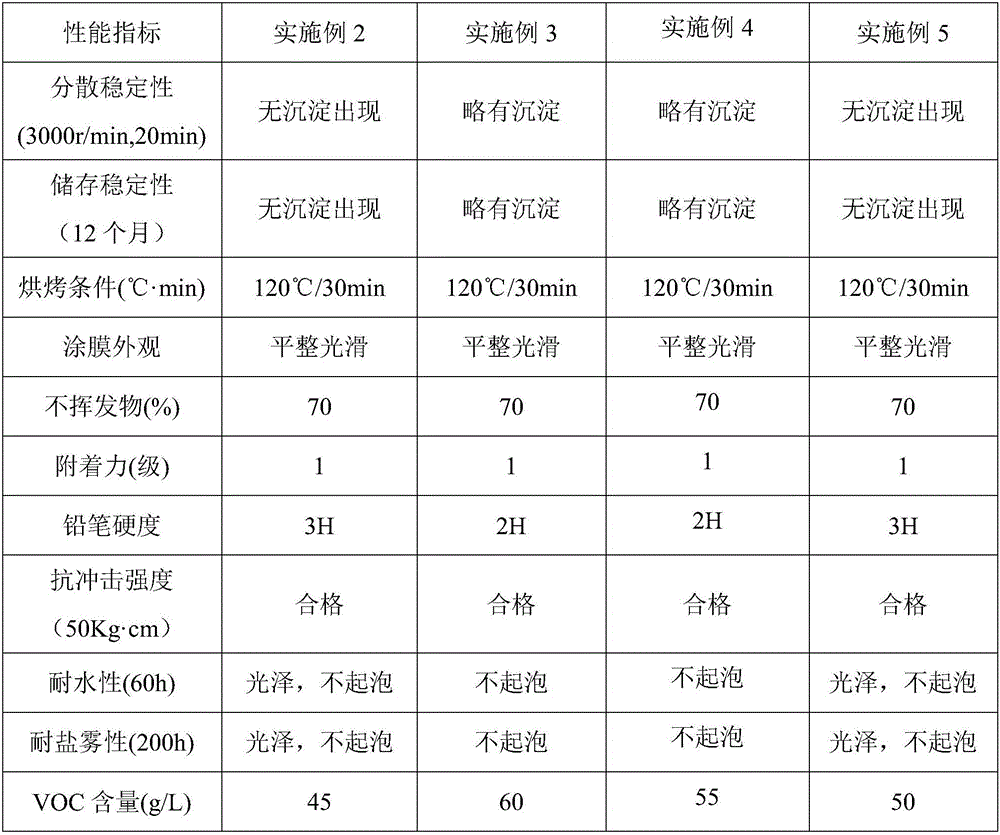

Examples

Embodiment 1

[0020] Put bisphenol A epoxy resin with a molar ratio of 1:1 and a monobasic acid or a dibasic acid in a three-necked flask, and add n-butanol and propylene glycol methyl ether with an equal mass ratio of 1:2 to 2:1 as Solvent, and dimethylethanolamine as catalyst, the amount of catalyst used is 1% to 2% of the mass of bisphenol A epoxy resin, the temperature is controlled by a constant temperature magnetic stirrer at 90 to 115°C, and the stirring speed is 600r / min for esterification When the acid value of the system drops to 5mgKOH / g, it is the end of the reaction. In addition, put a certain mass ratio of α-methacrylic acid, methyl methacrylate and n-butyl acrylate in another three-necked flask, and then add the same mass ratio of 1:1:1 to 2:2:1 n-butanol, propylene glycol methyl ether, butyl acetate as solvent, and azobisisobutyronitrile as initiator, n-dodecanethiol as chain transfer agent, the amount of initiator and chain transfer agent is α-methyl 1% to 2.5% of the mass...

Embodiment 2

[0023] A total of 30 parts of bisphenol A epoxy resin E-20 and n-octanoic acid with a molar ratio of 1:1 were placed in a three-necked flask, and an equal mass of n-butanol and propylene glycol methyl ether with a volume ratio of 1:2 was added as a solvent. And dimethylethanolamine is used as catalyzer, and the consumption of catalyzer is 1% of bisphenol A type epoxy resin quality, is 105 ℃ by constant temperature magnetic stirrer control temperature, and stirring speed is 600r / min to carry out esterification reaction, system acid value drops When reaching 5mgKOH / g, it is the end of the reaction. In addition, a total of 60 parts of α-methacrylic acid, methyl methacrylate and n-butyl acrylate with a mass ratio of 2:1:1 were placed in another three-necked flask, and the same amount of : 1 n-butanol, propylene glycol methyl ether, butyl acetate as solvent, and azobisisobutyronitrile as initiator, n-dodecanethiol as chain transfer agent, the consumption of initiator and chain tran...

Embodiment 3

[0026]Put 40 parts of bisphenol A epoxy resin E-20 and adipic acid with a molar ratio of 1:1 in a three-necked flask, and add the same mass of n-butanol and propylene glycol methyl ether with a volume ratio of 2:1 as a solvent , and dimethylethanolamine as a catalyst, the amount of the catalyst is 2% of the mass of bisphenol A type epoxy resin, the temperature is controlled by a constant temperature magnetic stirrer to be 90 ° C, and the stirring speed is 600r / min to carry out the esterification reaction, the acid value of the system When it drops to 5mgKOH / g, it is the end of the reaction. In addition, a total of 70 parts of α-methacrylic acid, methyl methacrylate and n-butyl acrylate with a mass ratio of 1:1:1 were placed in another three-necked flask, and the same mass ratio of 2:2 : 1 n-butanol, propylene glycol methyl ether, butyl acetate as solvent, and azobisisobutyronitrile as initiator, n-dodecanethiol as chain transfer agent, the consumption of initiator and chain tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com