Biodegradable fat-aromatic copolyester with low carboxyl content and continuous preparation method thereof

A technology of aromatic copolyester and biodegradation, which is applied in the field of biodegradable fat-aromatic copolyester and its continuous preparation, which can solve the problem of low control level of carboxyl group content, only semi-continuous production, product quality batch differences, etc. problem, to achieve the effect of large molecular weight, high degree of automation, and no batch difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

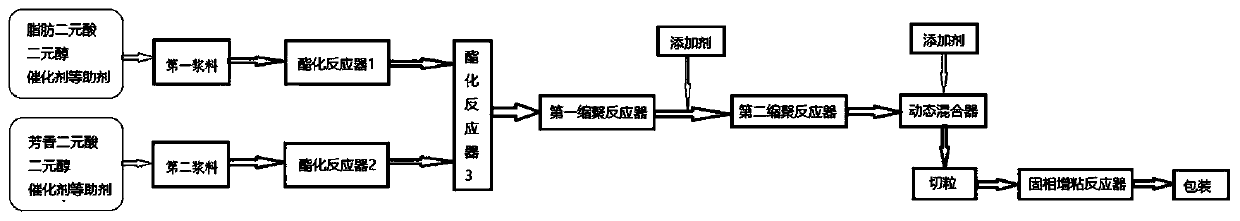

[0035] First, the embodiment of the present application provides a continuous preparation method of biodegradable aliphatic-aromatic copolyester with low carboxyl content, such as figure 1 As shown, it mainly includes the following steps:

[0036] step 1 :

[0037] (a): One or several kinds of fatty dibasic acids and one or several kinds of dibasic alcohols are formulated into the first slurry and continuously added to the first esterification reactor (esterification reactor 1) for esterification reaction to obtain fatty acid ester compound E1.

[0038] Wherein, the alkyd molar ratio of the first slurry, that is, the molar ratio of dihydric alcohol and fatty dibasic acid is 0.8 to 3, such as 0.8, 1, 1.2, 1.5, 1.8, 2, 2.3, 2.5, 2.7, 3 or An intermediate value between any two numeric values. Fatty dibasic acid is one or more of succinic acid, glutaric acid, adipic acid, sebacic acid and dimer acid; dibasic alcohol is ethylene glycol, 1,2-propanediol, 1,3- One of propylene ...

Embodiment 1

[0064] This embodiment provides a biodegradable aliphatic-aromatic copolyester, which is prepared according to the following preparation process:

[0065] Adipic acid and 1,4-butanediol are formulated into the first slurry at a molar ratio of 1:1.6, and then continuously fed into the first esterification reactor at a flow rate of 2685kg / h for esterification reaction: at 200 °C and an absolute pressure of 90kpa, stay for 5 hours, and the obtained fatty acid esterification product is continuously sent to the third esterification reactor.

[0066] Prepare terephthalic acid and 1,4-butanediol in a molar ratio of 1:2 to form the second slurry, add 1% titanium catalyst relative to the weight of the second slurry, and then feed it continuously at a flow rate of 2325kg / h Carry out esterification reaction in the second esterification reactor: stay at 250°C and normal pressure for 6 hours, and the obtained aromatic esterification product is continuously sent to the third esterification ...

Embodiment 2

[0072] This embodiment provides a biodegradable aliphatic-aromatic copolyester, which is prepared according to the following preparation process:

[0073] Blend succinic acid and 1,4-butanediol in a molar ratio of 1:1.8 to form the first slurry, add 0.2% titanium catalyst by weight of the first slurry, and then continuously send it to the first slurry at a flow rate of 3420kg / h Carry out the esterification reaction in the esterification reactor, stay at 200° C. and an absolute pressure of 50 kpa for 4 hours, and the obtained fatty acid esterification product is continuously sent into the third esterification reactor.

[0074] Prepare terephthalic acid and 1,4-butanediol in a molar ratio of 1:2 to form the second slurry, add 0.5% titanium catalyst relative to the weight of the second slurry, and then continuously send it to the Carry out esterification reaction in the second esterification reactor, stay at 250°C and normal pressure for 6 hours, and the obtained aromatic esterif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com