Nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof

A technology of nanocellulose and high carboxyl group, which can be applied to artificial filaments made of cellulose derivatives, processing wastewater treatment, alkali metal oxides/hydroxides, etc. The subsequent use of nanocellulose and the large loss of cellulose can achieve the effect of high carboxyl group content, increasing total carboxyl group content, and improving oxidation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

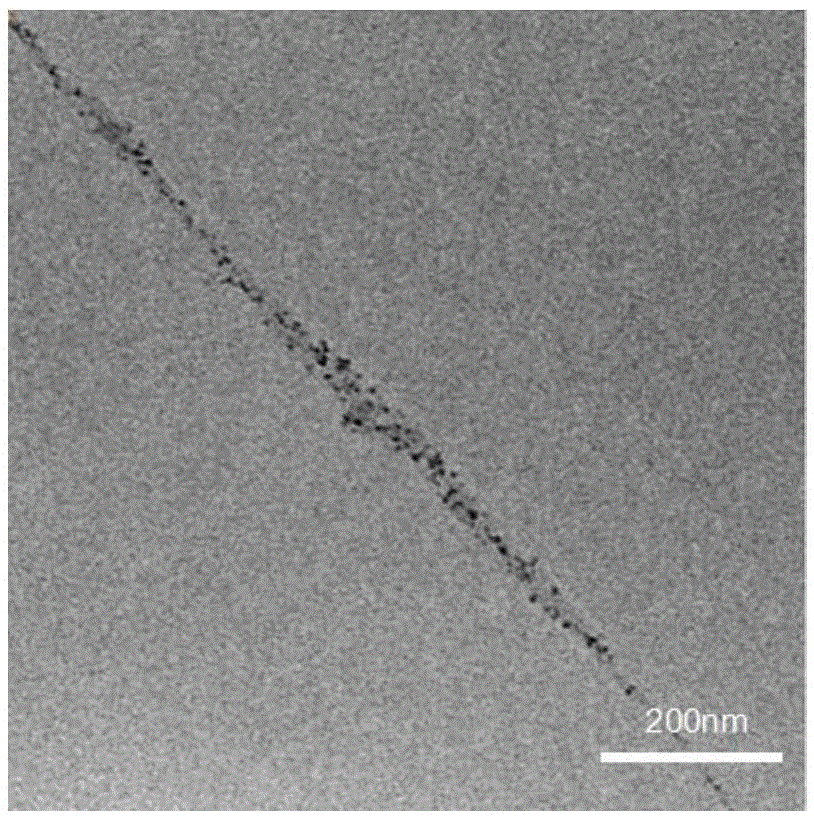

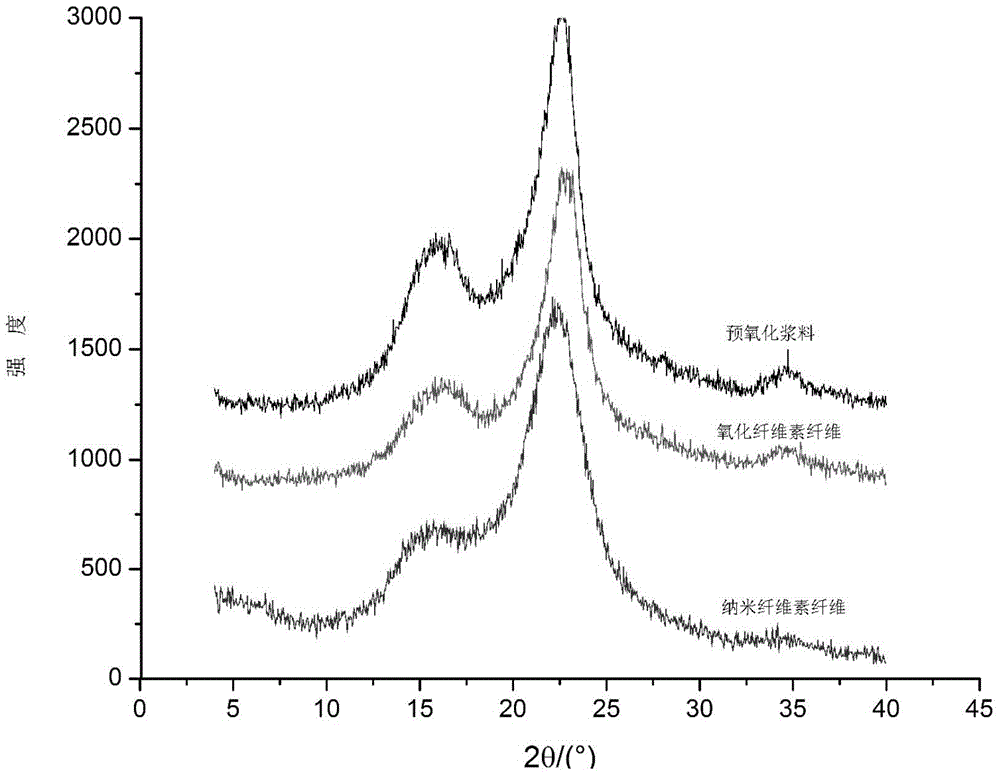

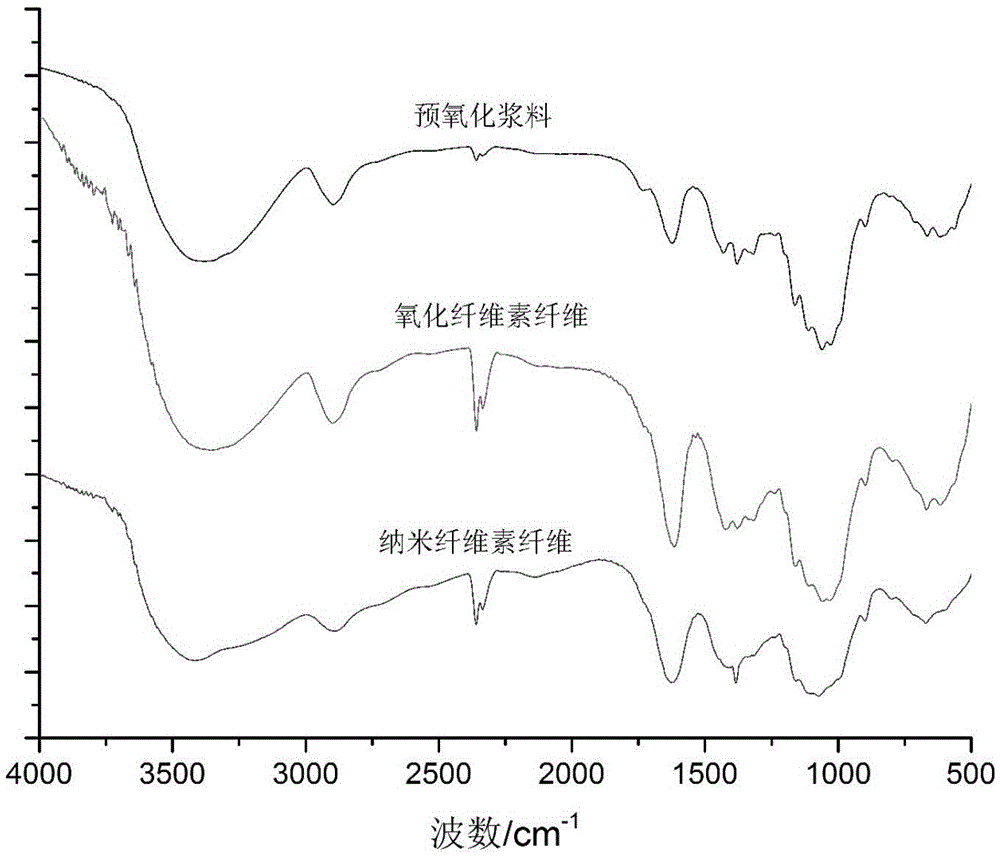

[0033] (1) Take 5g of dry and bleached bamboo pulp, tear it into small pieces and disperse in 1000ml deionized water, disperse the slurry evenly with a high-speed disperser, add 7g of sodium periodate to the slurry, and then place it in a heat-collecting magnetic In the stirrer, set the temperature to 50°C and react for 0.5h to obtain the pretreated slurry. Its yield is 90.952% through sampling test.

[0034] (2) Add 700ml of 0.2M NaClO to the pretreated slurry obtained in step (1) 2 solution and 50ml of 1M acetic acid solution, mixed evenly, placed in a heat-collecting magnetic stirrer, set the temperature at 30°C, and reacted for 1h to obtain a pre-oxidized slurry. At the same time, parallel experiments were done, and the obtained pre-oxidized slurry was used to test the yield of the slurry: washed with distilled water for 3 times, wrung out, dried in vacuum -0.1Mpa, 60°C, 10h, the measured fiber yield was 75.713%, and the carboxyl content was 75.713%. It is 0.6231 mmol / g....

Embodiment 2

[0041] (1) Take 10g of absolutely dry bleached bamboo pulp, tear it into small pieces and disperse it in 1000ml deionized water, disperse the slurry evenly with a high-speed disperser, add 8.2g of sodium periodate to the slurry, and then place it in a heat collecting type In the magnetic stirrer, set the temperature to 55° C., and react for 1 hour to obtain the pretreated slurry. Its yield is 90.795% through sampling test.

[0042] (2) Add 800ml of 0.2M NaClO to the pretreated slurry obtained in step (1) 2 solution and 60ml of 1M acetic acid solution, mixed evenly, placed in a heat-collecting magnetic stirrer, set the temperature at 40°C, and reacted for 2 hours to obtain a pre-oxidized slurry. At the same time, parallel experiments were done, and the obtained pre-oxidized slurry was used to test the yield of the slurry: washed with distilled water for 3 times, wrung out, and dried in a vacuum at -0.1Mpa, 60°C, for 12 hours, the measured fiber yield was 76.232%, and the carbo...

Embodiment 3

[0047] (1) Take 15g of dry and bleached bamboo pulp, tear it into small pieces and disperse in 1000ml deionized water, disperse the slurry evenly with a high-speed disperser, add 9g of sodium periodate to the slurry, and then place it in a heat-collecting magnetic In the stirrer, set the temperature to 60° C., and react for 1.5 hours to obtain the pretreated slurry. Its yield is 90.647% through sampling test.

[0048] (2) Add 900ml of 0.2M NaClO to the pretreated slurry obtained in step (1) 2 solution and 70ml of 1M acetic acid solution, mixed evenly, placed in a heat-collecting magnetic stirrer, set the temperature at 50°C, and reacted for 3 hours to obtain a pre-oxidized slurry. At the same time, parallel experiments were done, and the obtained pre-oxidized slurry was used to test the yield of the slurry: washed with distilled water for 3 times, wrung out, dried in vacuum -0.1Mpa, 60°C, 12h, the measured fiber yield was 75.696%, and the carboxyl content was 75.696%. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com