A kind of high carboxyl content nano cellulose fiber and its preparation and application

A technology of nanocellulose and high carboxyl group, applied in artificial filaments made of cellulose derivatives, processing wastewater treatment, alkali metal oxides/hydroxides, etc., can solve the problems of subsequent use of nanocellulose, fiber The problems of large loss of cellulose and low yield of nanocellulose can achieve the effect of increasing total carboxyl group content, high carboxyl group content and improving oxidation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

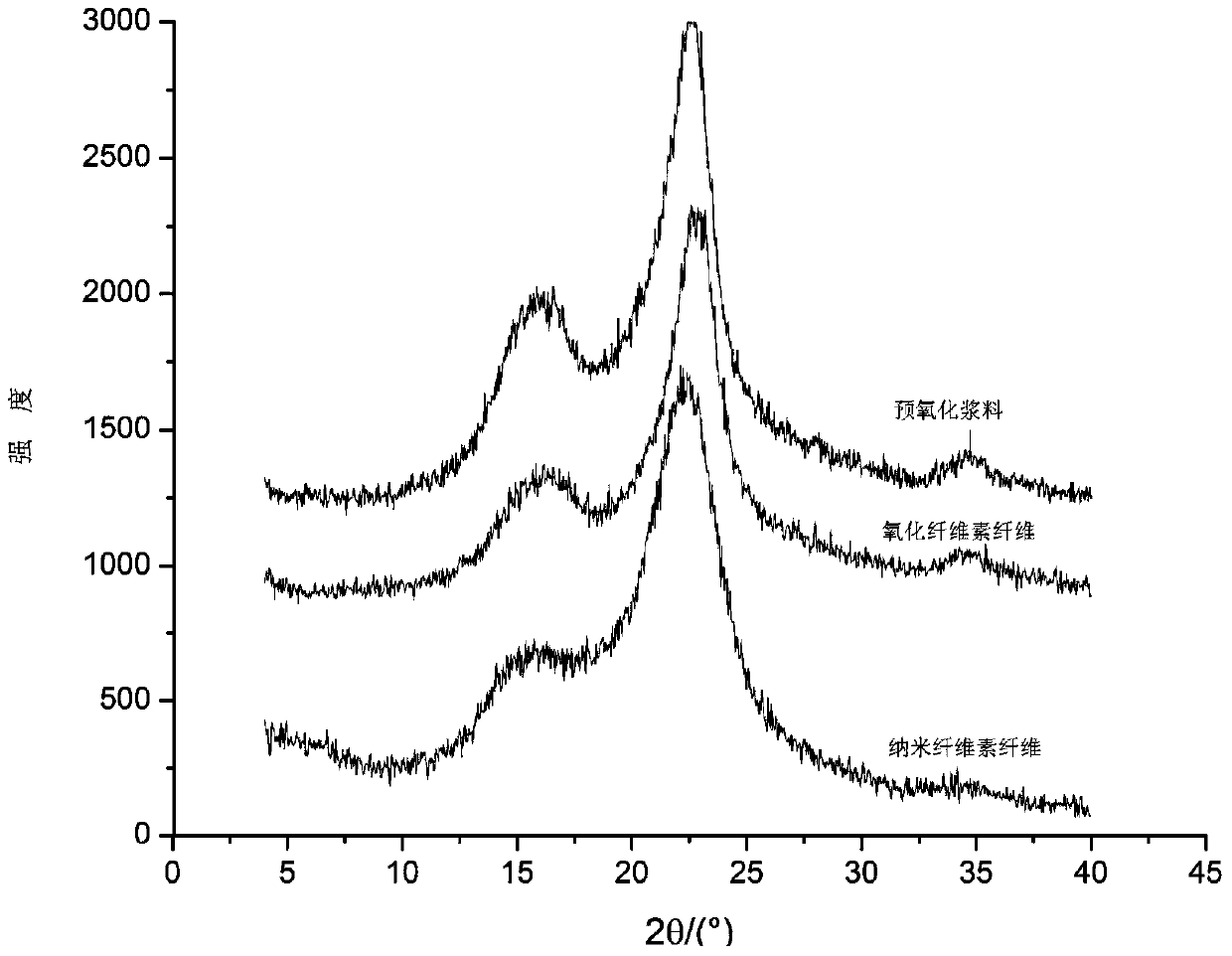

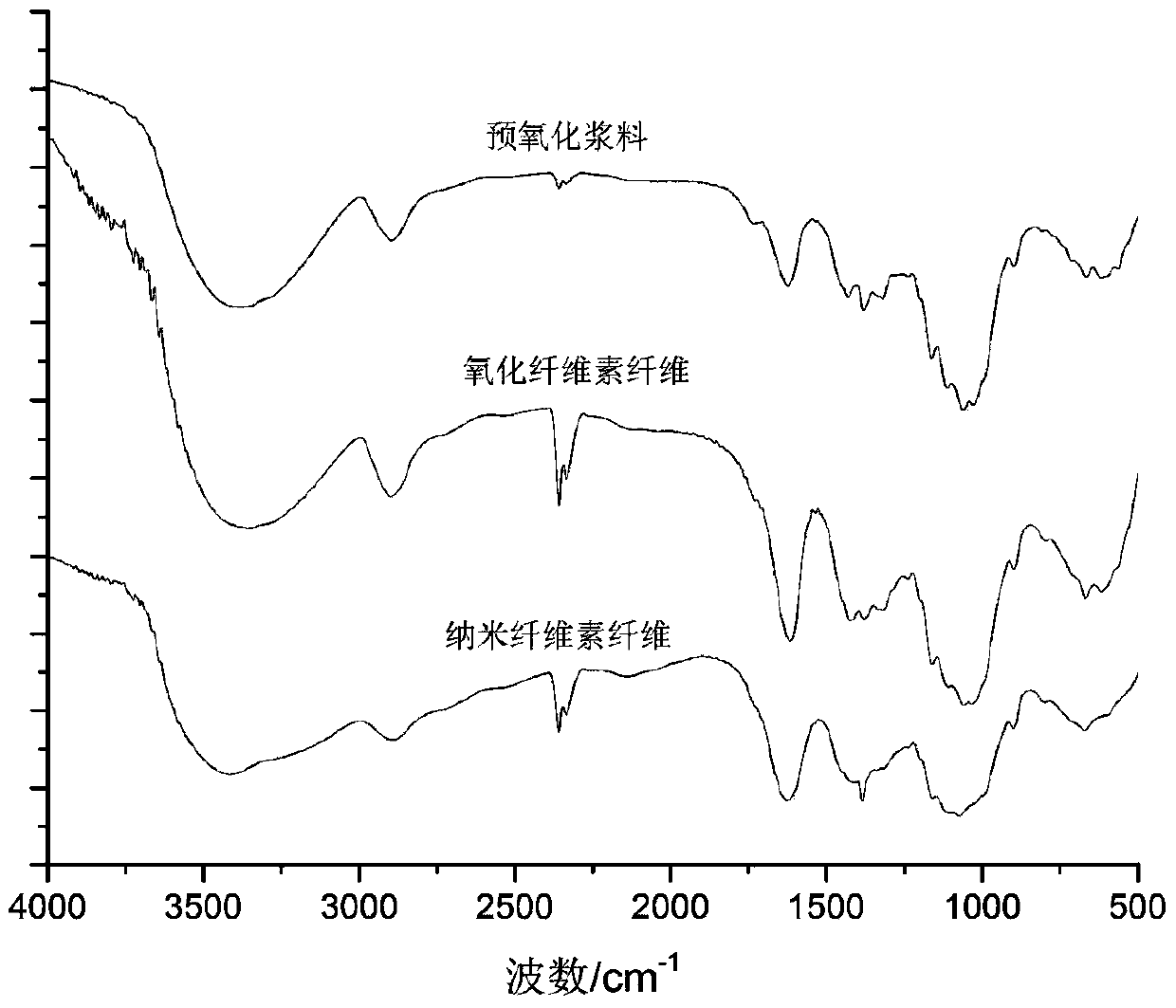

[0033] (1) Take 5g of dry and bleached bamboo pulp, tear it into small pieces and disperse in 1000ml deionized water, disperse the slurry evenly with a high-speed disperser, add 7g of sodium periodate to the slurry, and then place it in a heat-collecting magnetic In the stirrer, set the temperature to 50°C and react for 0.5h to obtain the pretreated slurry. Its yield is 90.952% through sampling test.

[0034] (2) Add 700ml of 0.2M NaClO to the pretreated slurry obtained in step (1) 2 solution and 50ml of 1M acetic acid solution, mixed evenly, placed in a heat-collecting magnetic stirrer, set the temperature at 30°C, and reacted for 1 hour to obtain a pre-oxidized slurry. At the same time, parallel experiments were done, and the obtained pre-oxidized slurry was used to test the yield of the slurry: washed with distilled water for 3 times, wrung out, dried in vacuum -0.1Mpa, 60°C, 10h, the measured fiber yield was 75.713%, and the carboxyl content was 75.713%. It is 0.6231 mmo...

Embodiment 2

[0041] (1) Take 10g of absolutely dry bleached bamboo pulp, tear it into small pieces and disperse it in 1000ml deionized water, disperse the slurry evenly with a high-speed disperser, add 8.2g of sodium periodate to the slurry, and then place it in a heat collecting type In the magnetic stirrer, set the temperature to 55° C., and react for 1 hour to obtain the pretreated slurry. Its yield is 90.795% through sampling test.

[0042] (2) Add 800ml of 0.2M NaClO to the pretreated slurry obtained in step (1) 2 solution and 60ml of 1M acetic acid solution, mixed evenly, placed in a heat-collecting magnetic stirrer, set the temperature at 40°C, and reacted for 2 hours to obtain a pre-oxidized slurry. At the same time, parallel experiments were done, and the obtained pre-oxidized slurry was used to test the yield of the slurry: washed with distilled water for 3 times, wrung out, and dried in a vacuum at -0.1Mpa, 60°C, for 12 hours, the measured fiber yield was 76.232%, and the carbo...

Embodiment 3

[0047] (1) Take 15g of dry and bleached bamboo pulp, tear it into small pieces and disperse in 1000ml deionized water, disperse the slurry evenly with a high-speed disperser, add 9g of sodium periodate to the slurry, and then place it in a heat-collecting magnetic In the stirrer, set the temperature to 60° C., and react for 1.5 hours to obtain the pretreated slurry. Its yield is 90.647% through sampling test.

[0048] (2) Add 900ml of 0.2M NaClO to the pretreated slurry obtained in step (1) 2 solution and 70ml of 1M acetic acid solution, mixed evenly, placed in a heat-collecting magnetic stirrer, set the temperature at 50°C, and reacted for 3 hours to obtain a pre-oxidized slurry. At the same time, parallel experiments were done, and the obtained pre-oxidized slurry was used to test the yield of the slurry: washed with distilled water for 3 times, wrung out, dried in vacuum -0.1Mpa, 60°C, 12h, the measured fiber yield was 75.696%, and the carboxyl content was 75.696%. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com