Patents

Literature

160 results about "Site selective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

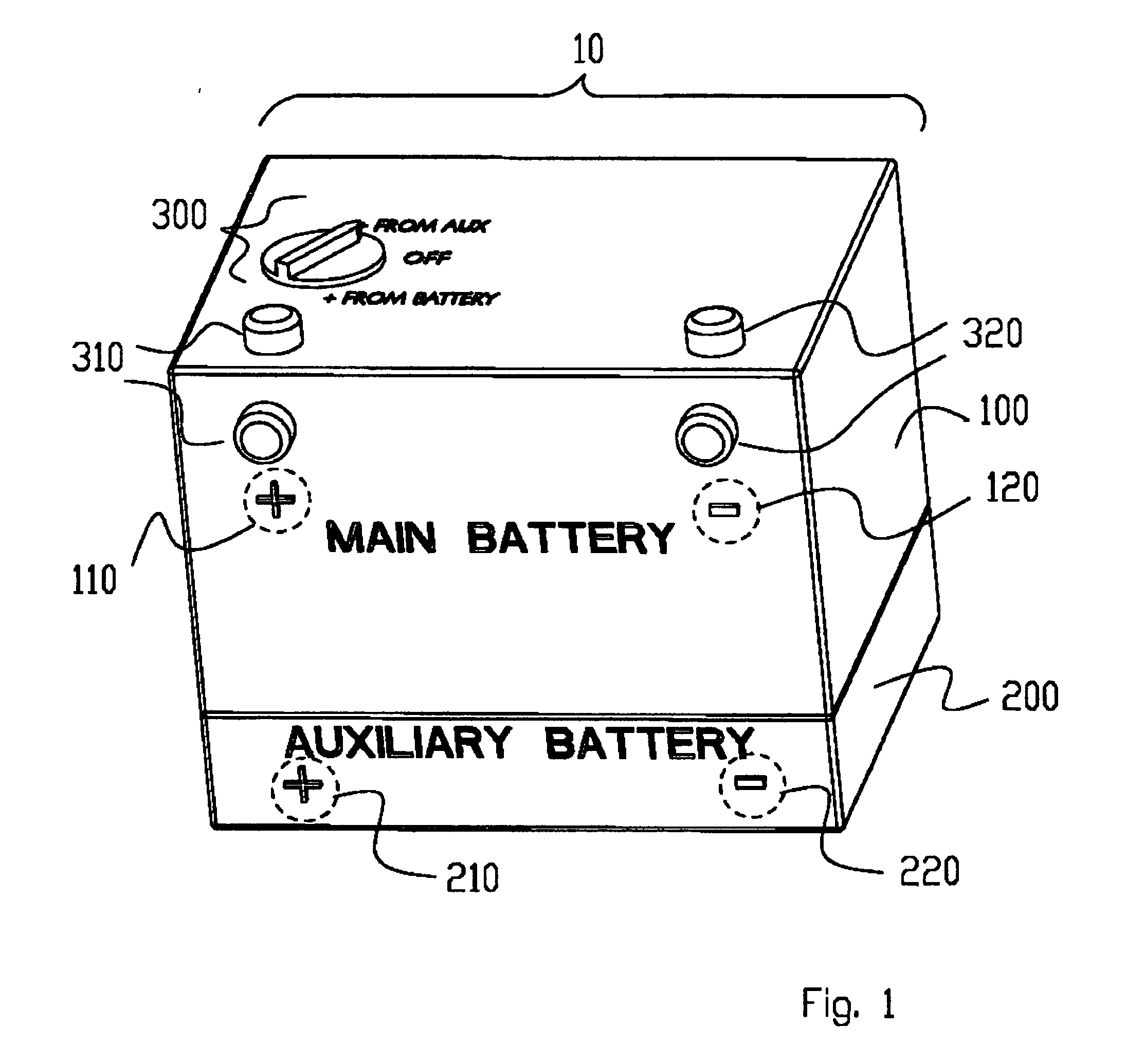

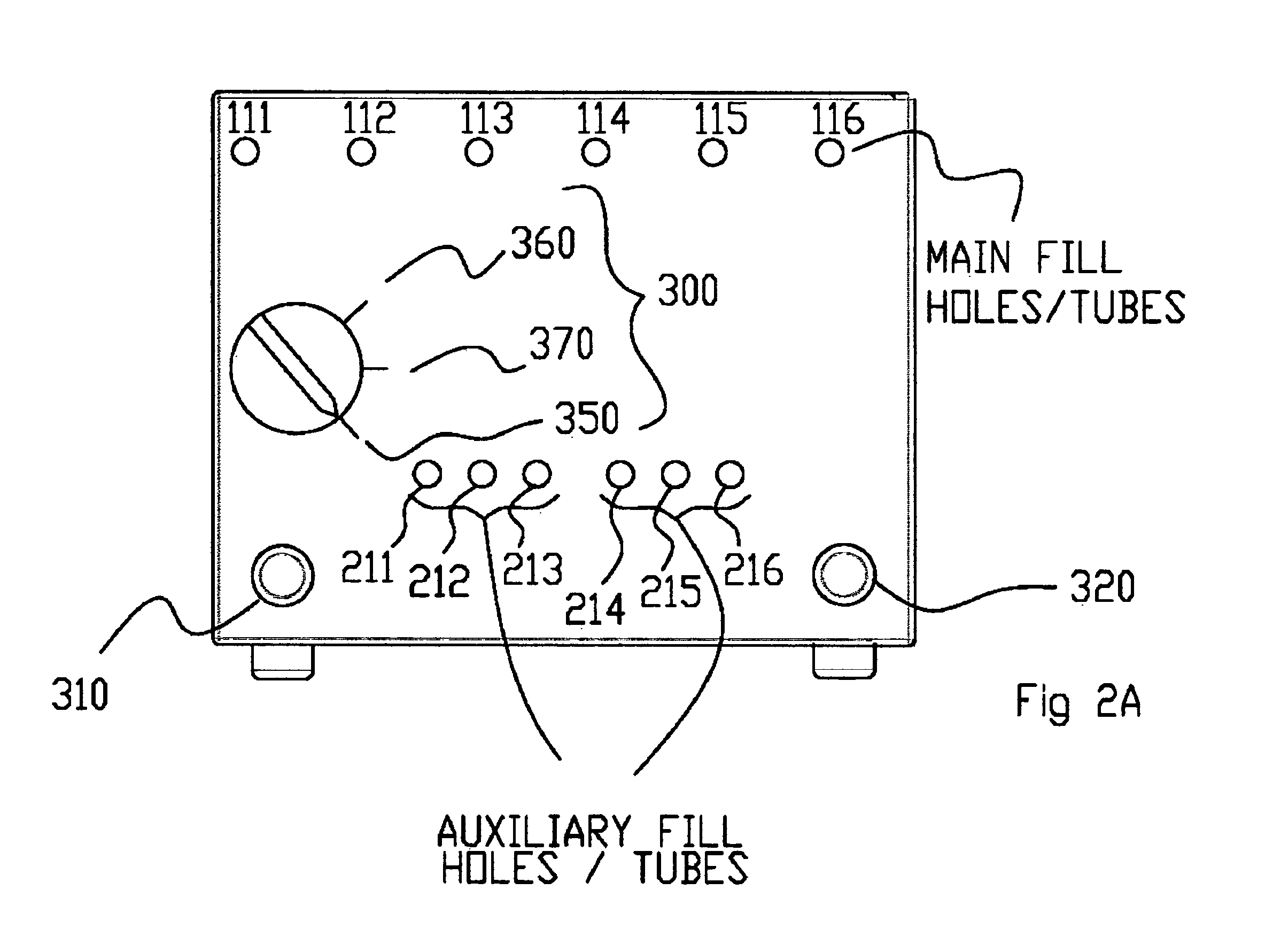

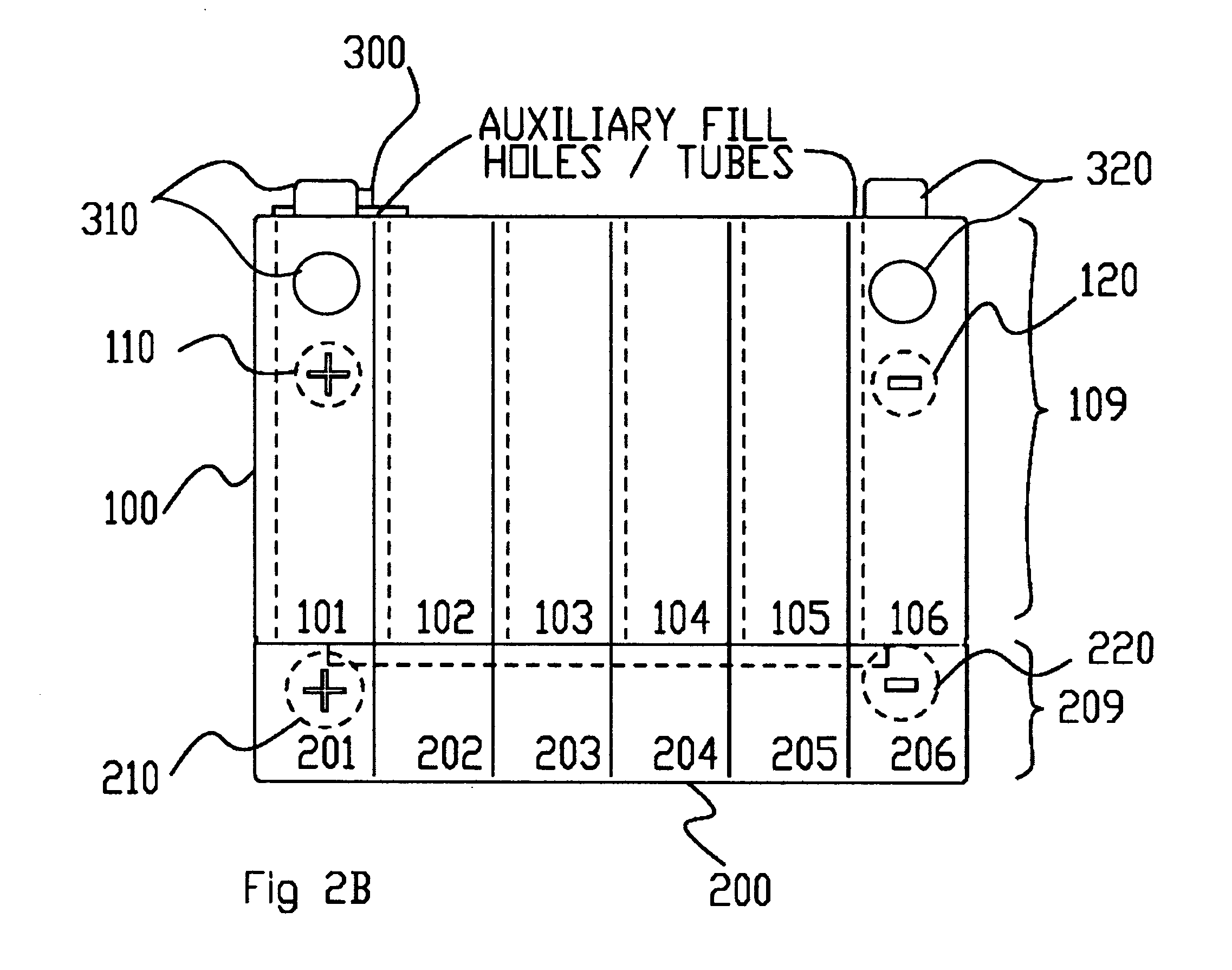

Multiple battery management system, auxiliary battery attachment system, and network controlled multiple battery system

InactiveUS20050035741A1Start fastIncrease costCharge equalisation circuitElectric devicesNetwork controlEngineering

The instant invention is directed to a multiple battery system and network controlled multiple battery system. A main battery having a main positive output and a main negative output is also provided, together with an at least one auxiliary battery having an at least one auxiliary positive output and an at least one auxiliary negative output. A main electrical circuit having an at least one switching device is provided with at least two operating positions. The two operating positions selectively couple the main and at least one auxiliary battery to the common positive terminal. In the first of the at least two operating positions electrical charge is provided to both the main battery and the at least one auxiliary battery. A controller is also provided and coupled to the main electrical circuit and switches the at least one switching device based on input from an at least one sensor.

Owner:RESERVE POWER CELL

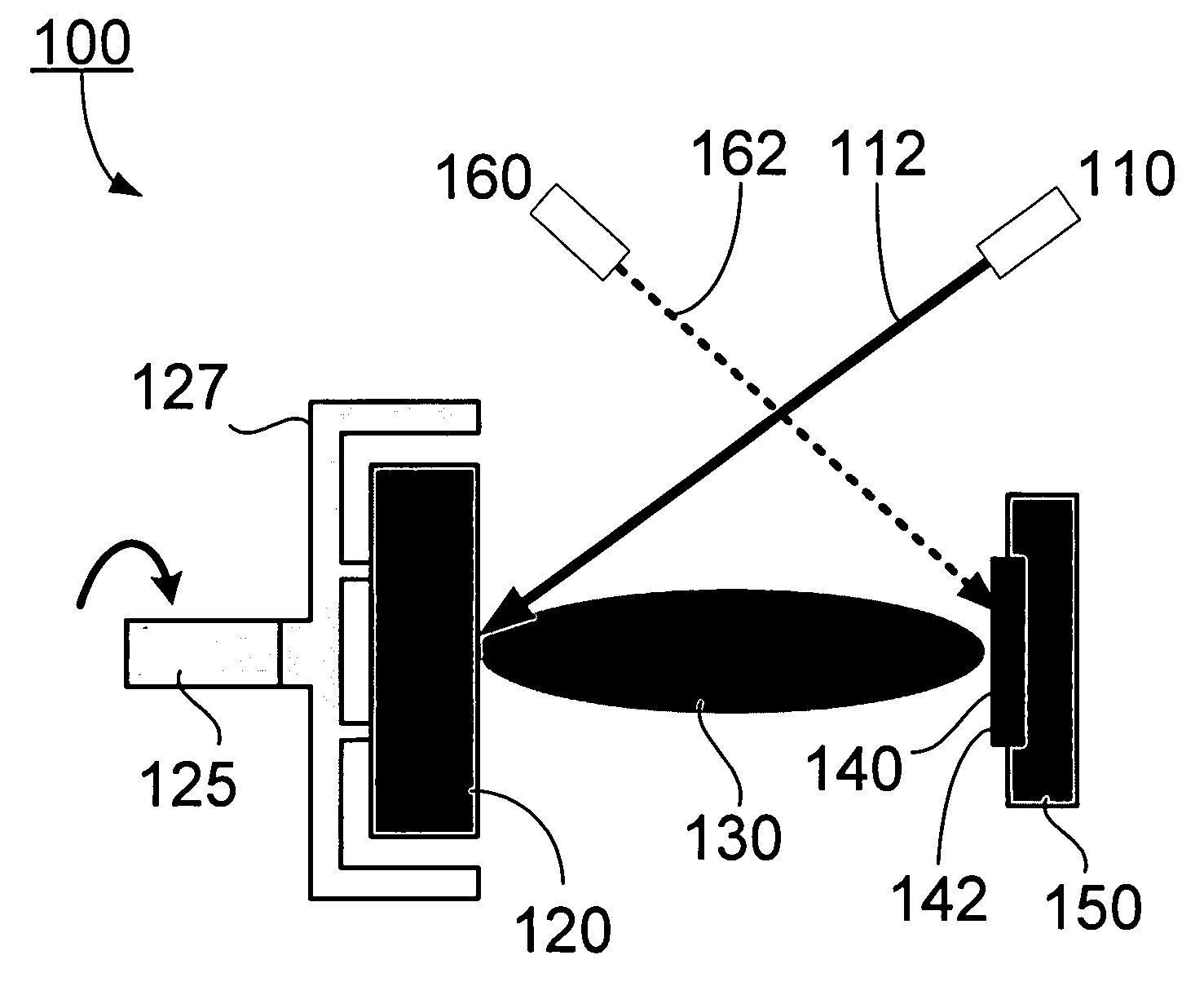

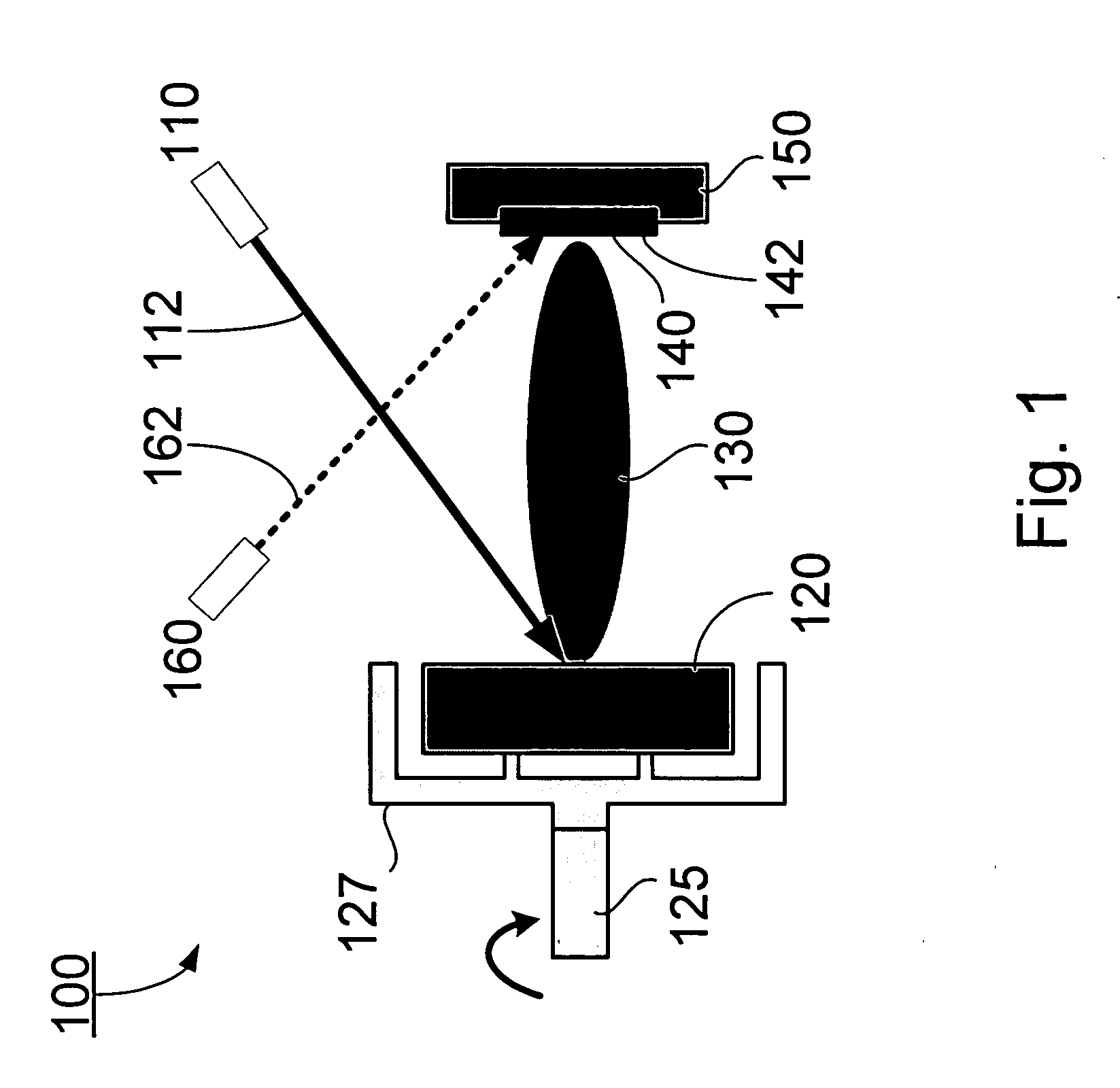

Microelectrical mechanical structure (MEMS) optical modulator and optical display system

InactiveUS20050002086A1Eliminating light attenuation of lightEliminating expenseTelevision system detailsColor television detailsPlanar substrateActuator

A MEMS optical display system includes an illumination source for providing illumination light, a collimating lens for receiving the illumination light and forming from it collimated illumination light, and a converging microlens array having an array of lenslets that converge the collimated illumination light. The converging microlens array directs the illumination light to a microelectrical mechanical system (MEMS) optical modulator. The MEMS optical modulator includes, for example, a planar substrate through which multiple pixel apertures extend and multiple MEMS actuators that support and selectively position MEMS shutters over the apertures. A MEMS actuator and MEMS shutter, together with a corresponding aperture, correspond to pixel. The light from the converging microlens array is focused through the apertures and is selectively modulated according to the positioning of the MEMS shutters by the MEMS actuators, thereby to impart image information on the illumination light. The light is then passed to a diffused transmissive display screen by a projection microlens array.

Owner:MICROSOFT TECH LICENSING LLC

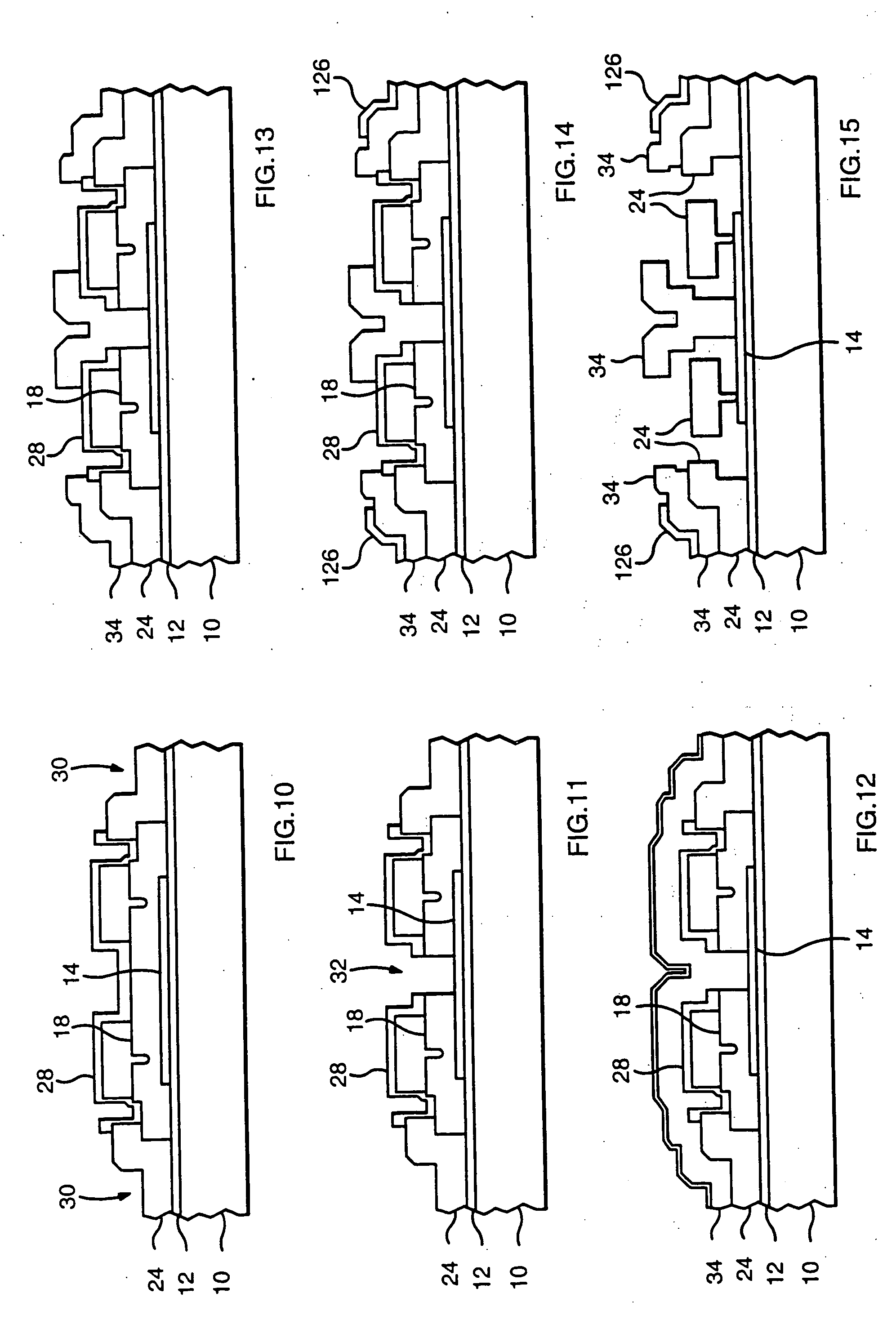

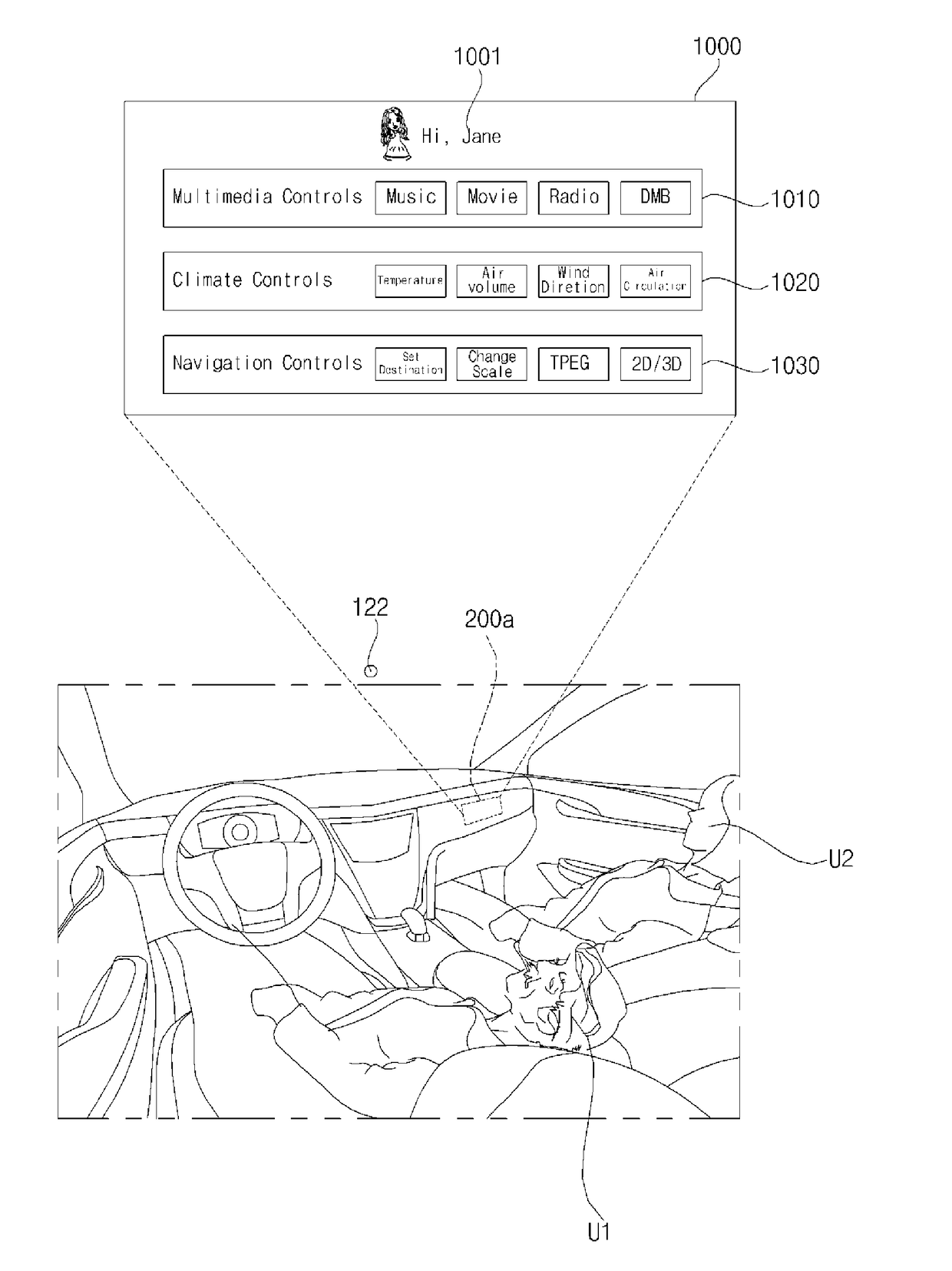

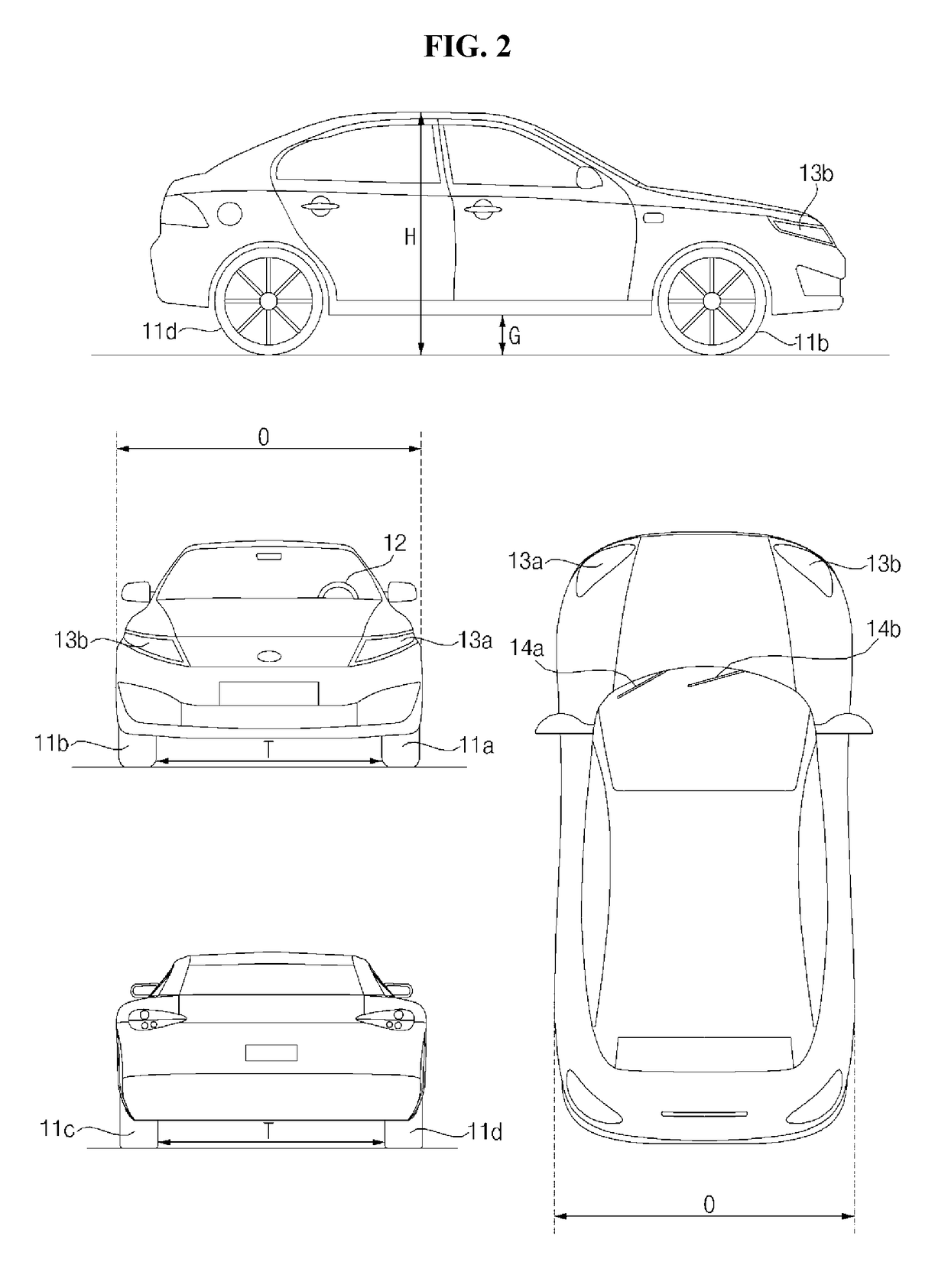

Vehicle and method for controlling the vehicle

ActiveUS20170124987A1Reduce the differenceSuppressing distraction of visionInstrument arrangements/adaptationsCathode-ray tube indicatorsSimulationDisplay device

Owner:LG ELECTRONICS INC

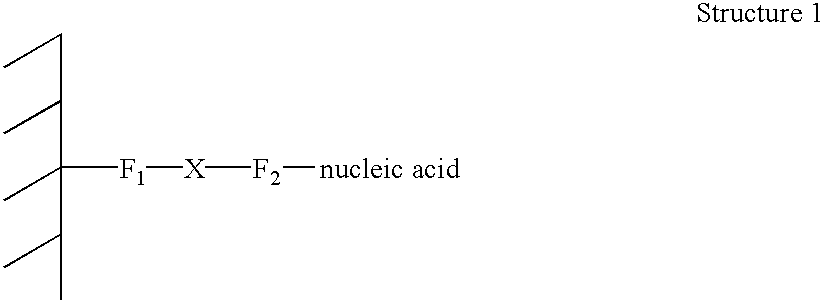

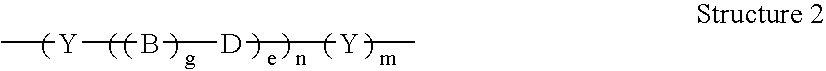

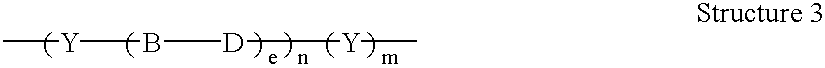

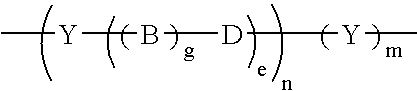

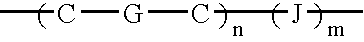

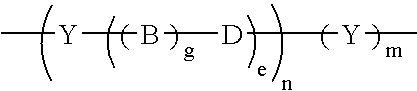

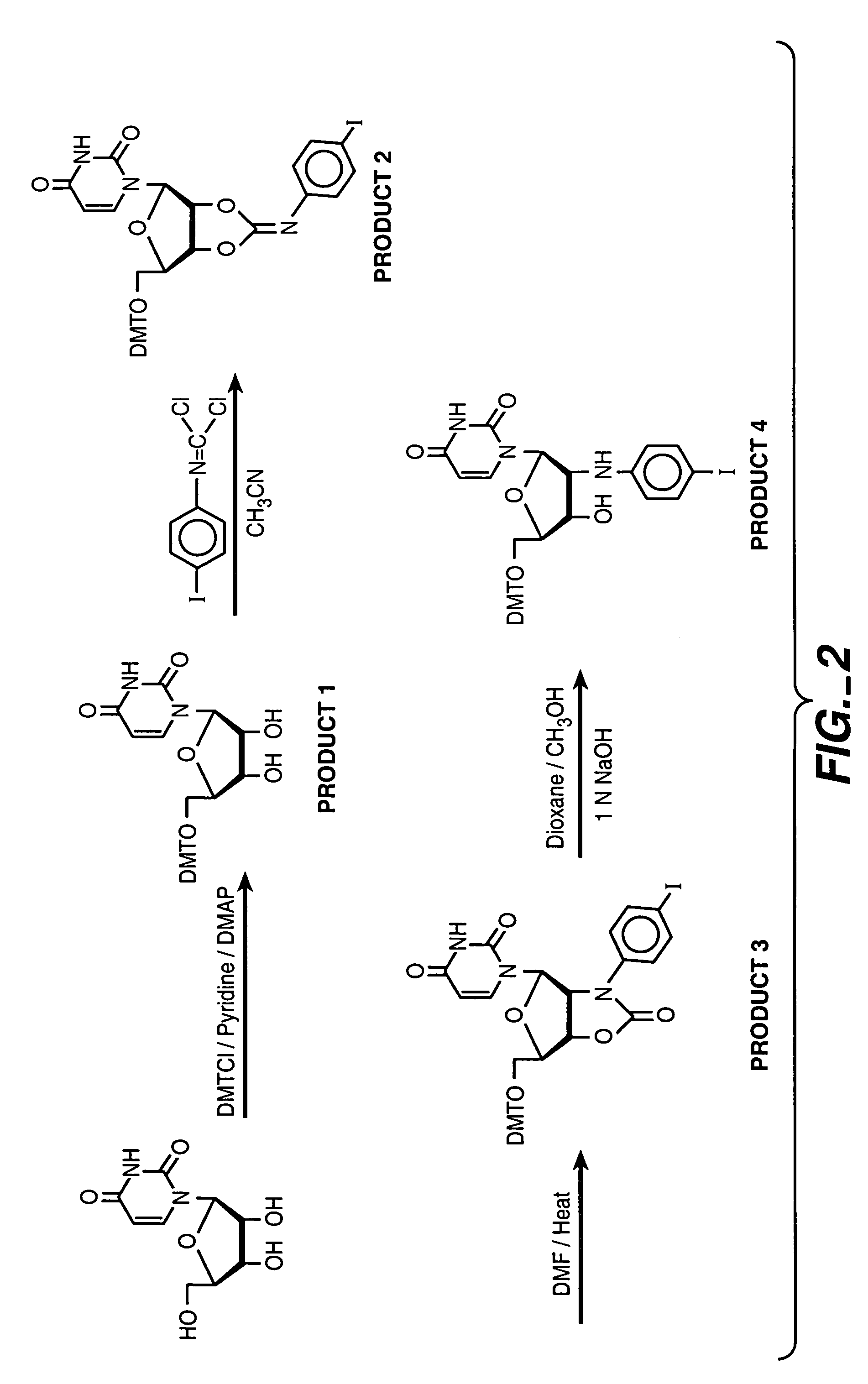

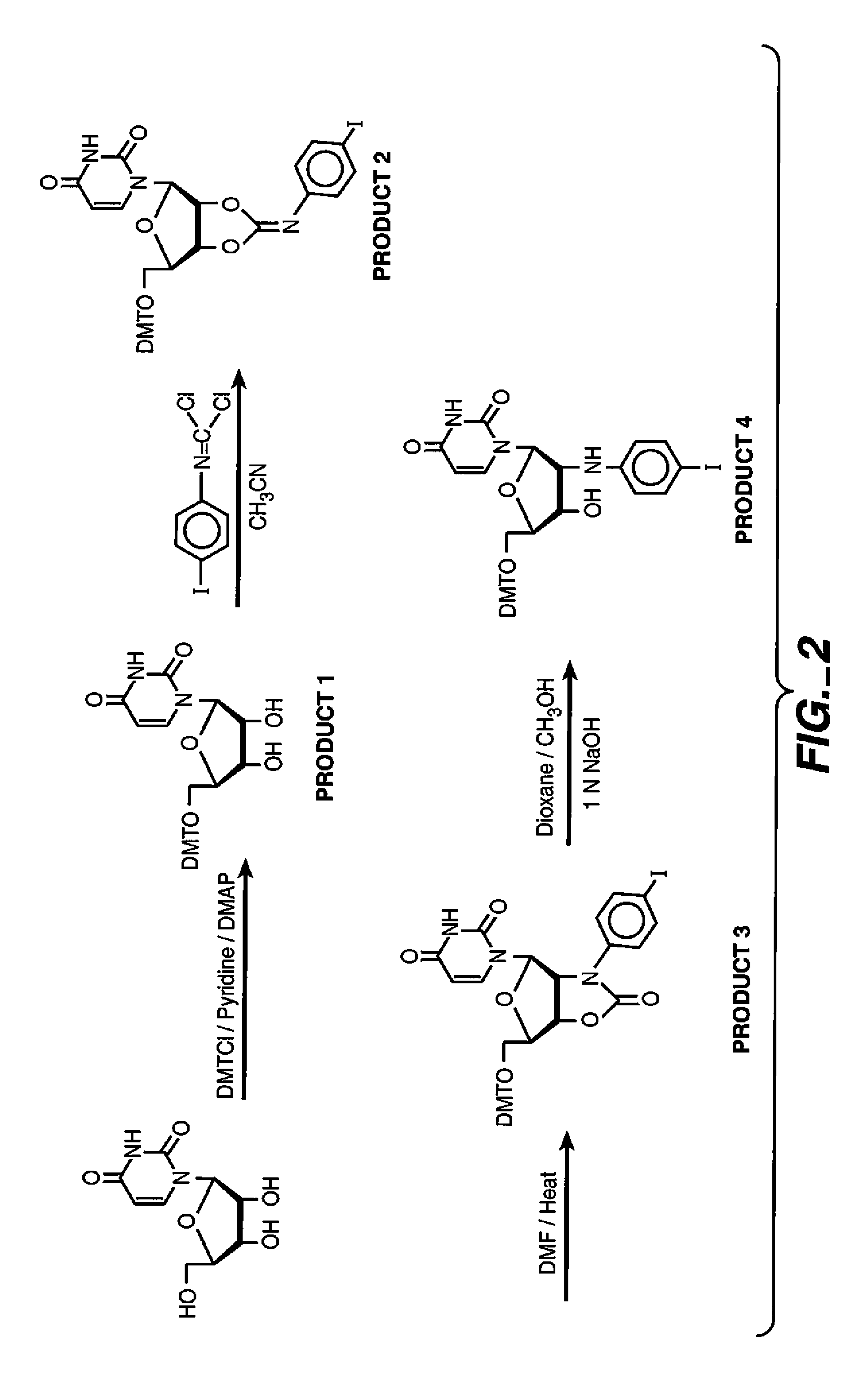

AC methods for the detection of nucleic acids

InactiveUS7056669B2Simple compositionBioreactor/fermenter combinationsBiological substance pretreatmentsOligomerBiological materials

The invention relates to nucleic acids covalently coupled to electrodes via conductive oligomers. More particularly, the invention is directed to the site-selective modification of nucleic acids with electron transfer moieties and electrodes to produce a new class of biomaterials, and to methods of making and using them.

Owner:ROCHE MOLECULAR SYST INC +1

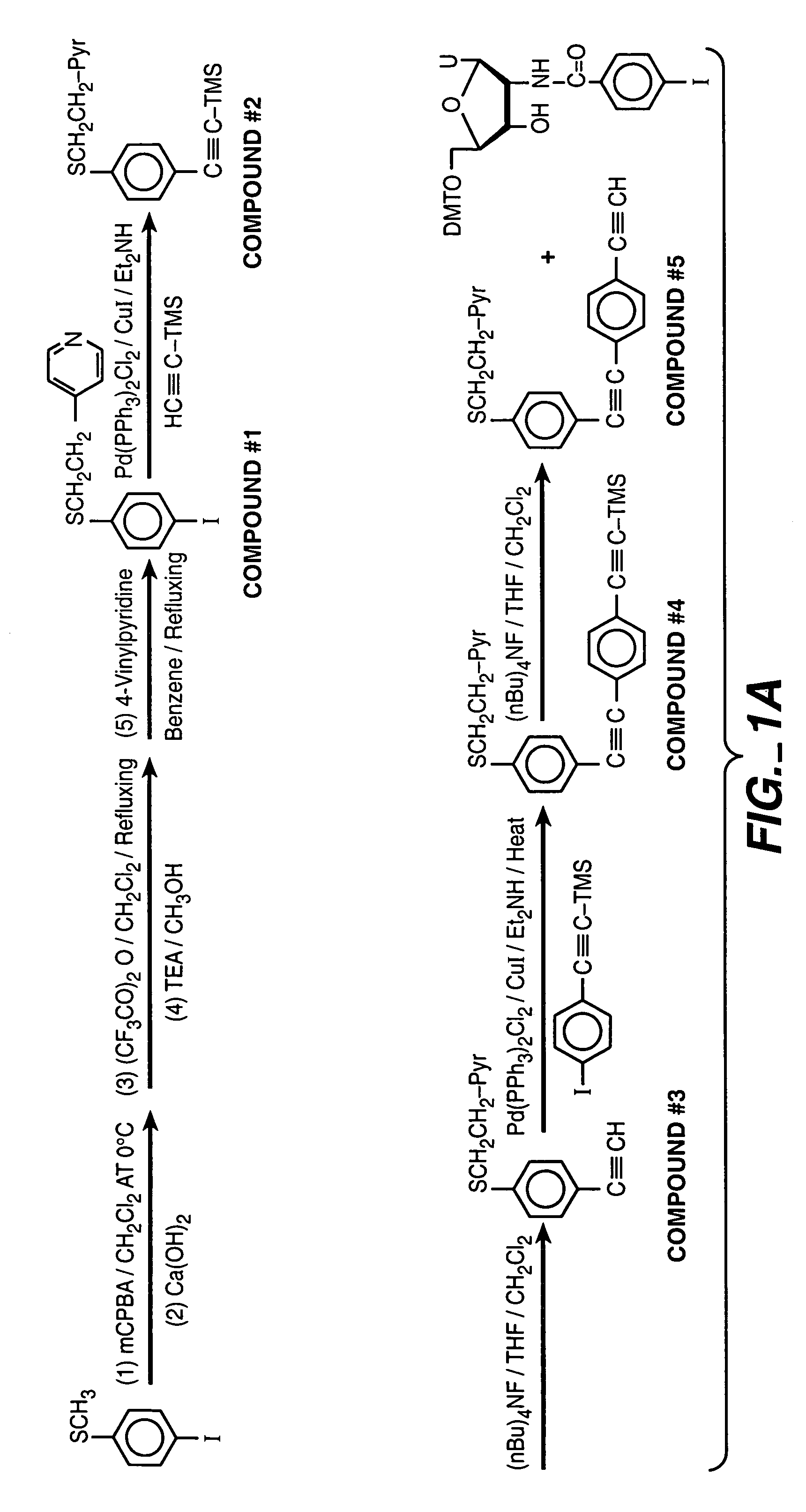

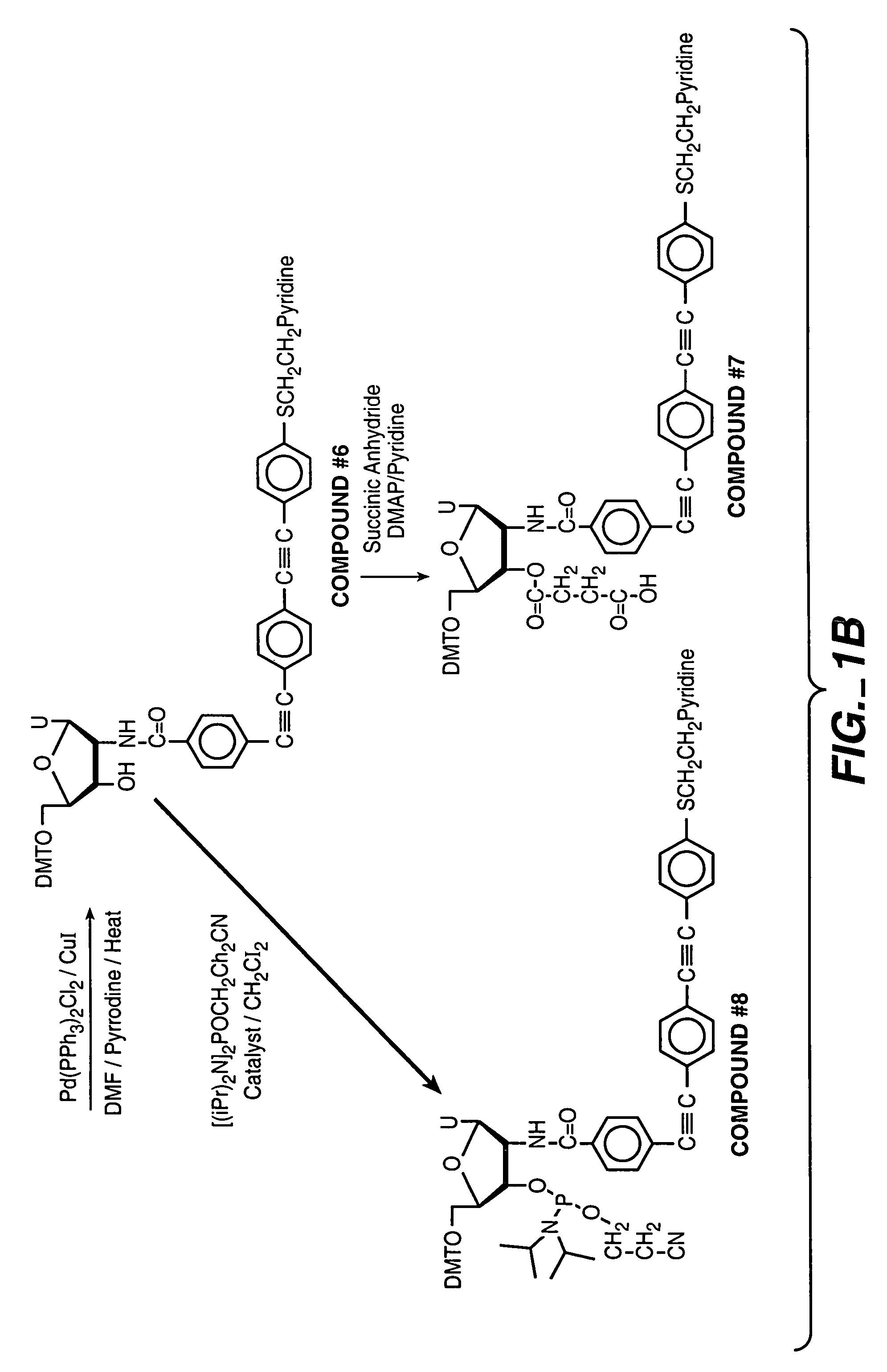

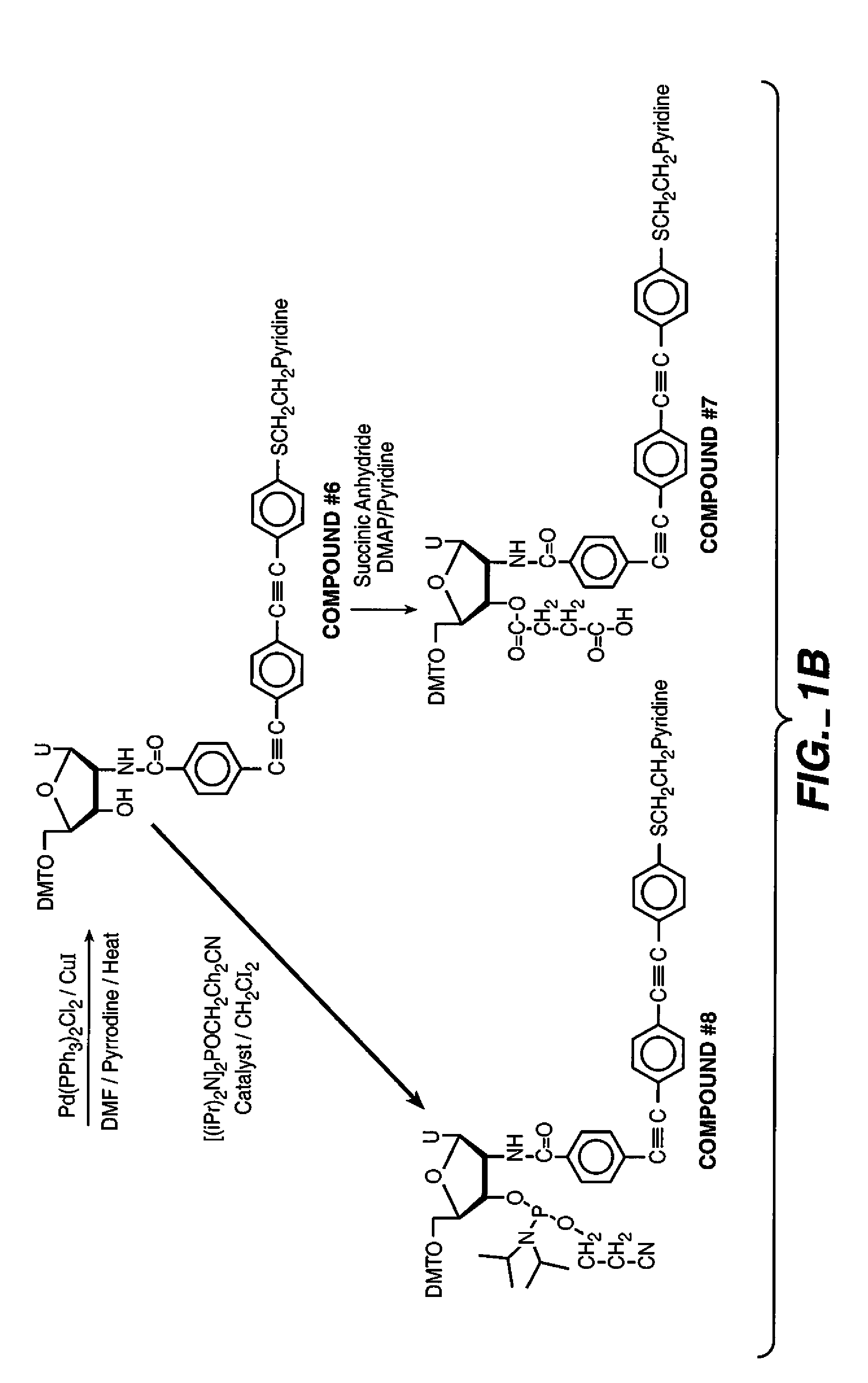

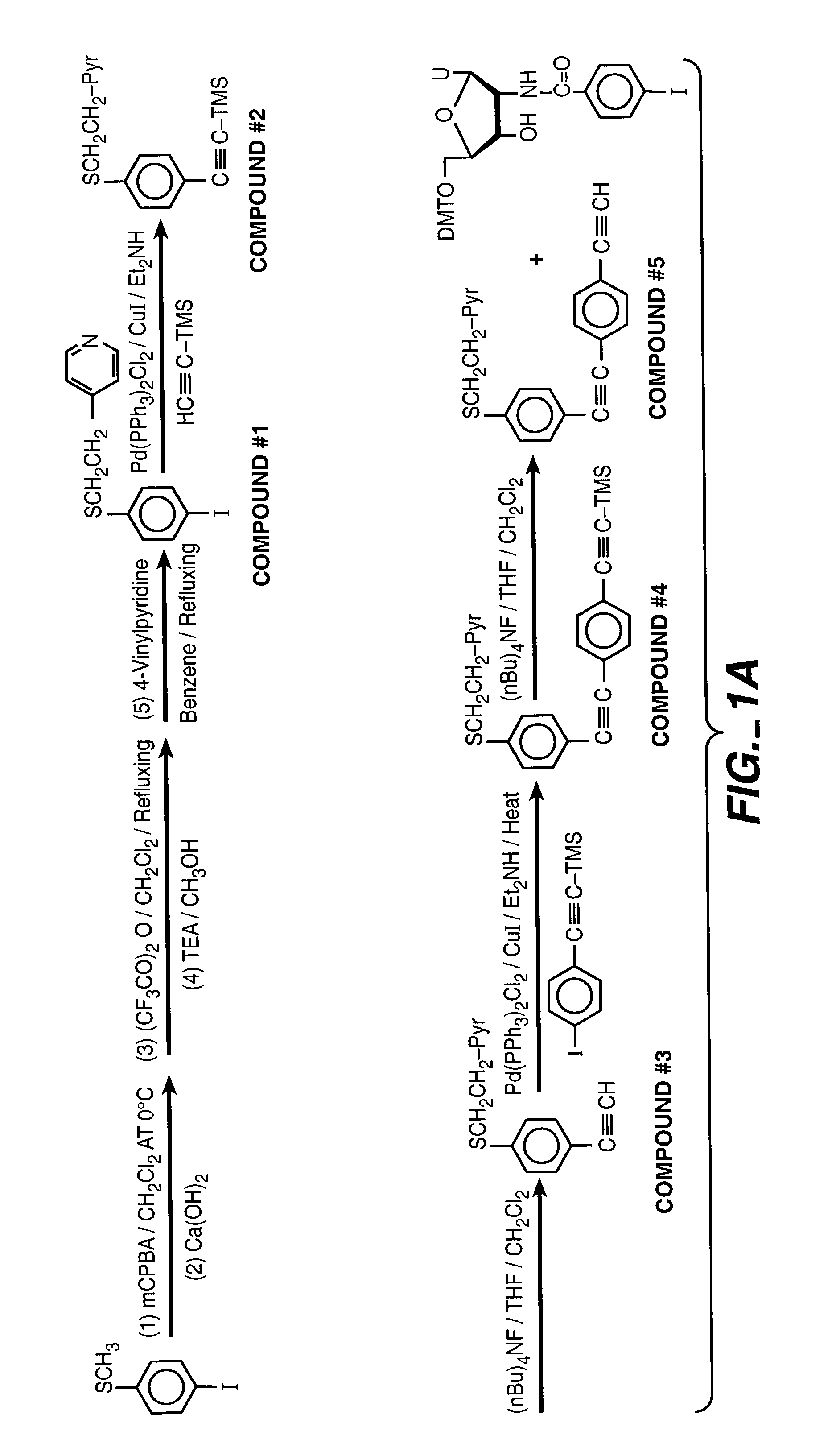

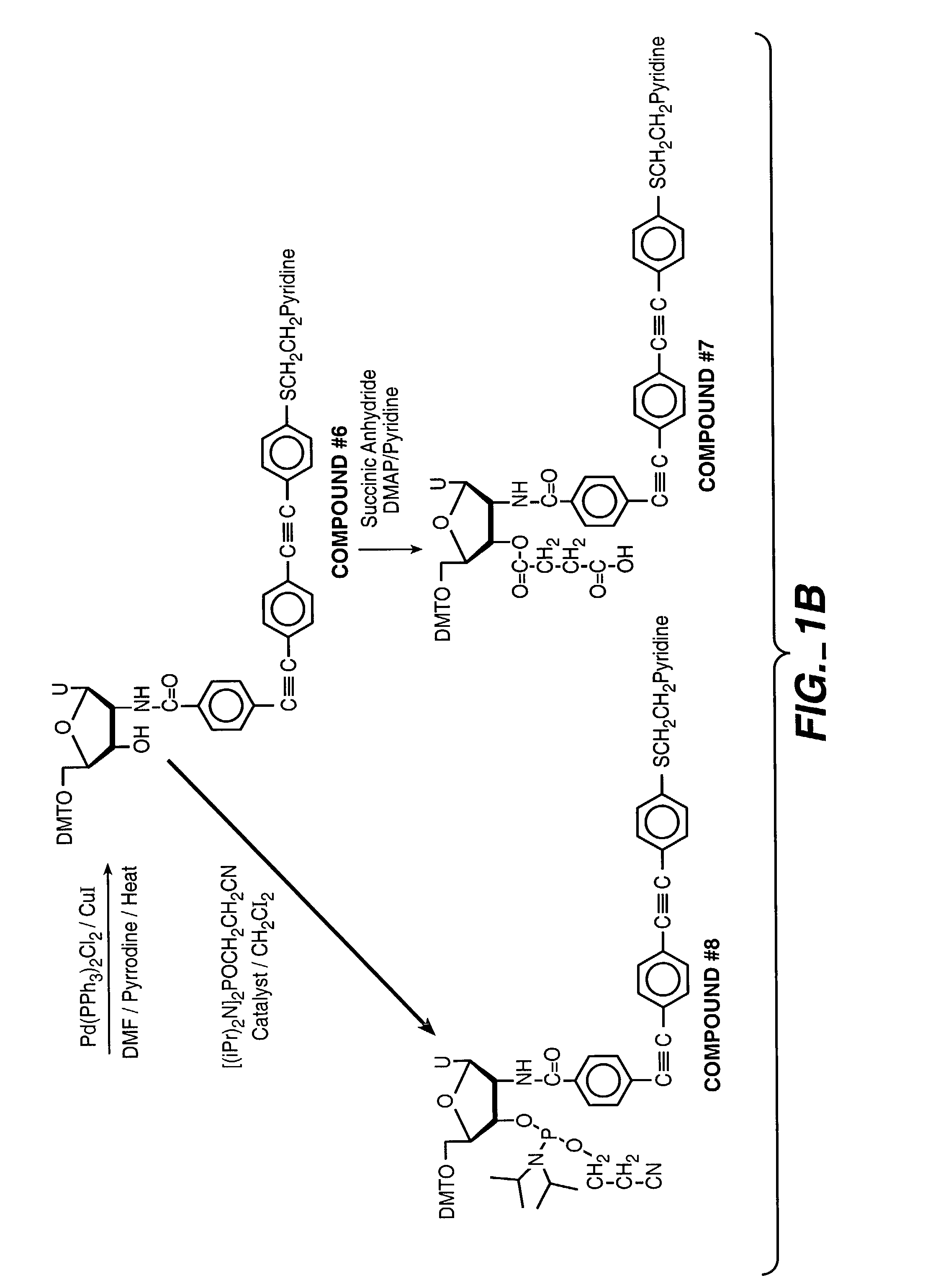

Conductive oligomers attached to electrodes and nucleoside analogs

InactiveUS7014992B1Bioreactor/fermenter combinationsBiological substance pretreatmentsOligomerElectron transfer

The invention relates to nucleic acids covalently coupled to electrodes via conductive oligomers. More particularly, the invention is directed to the site-selective modification of nucleic acids with electron transfer moieties and electrodes to produce a new class of biomaterials, and to methods of making and using them.

Owner:ROCHE MOLECULAR SYST INC +1

Electronic transfer moieties attached to peptide nucleic acids

InactiveUS7045285B1Simple compositionBioreactor/fermenter combinationsMaterial nanotechnologyOligomerConductive polymer

The invention relates to nucleic acids covalently coupled to electrodes via conductive oligomers. More particularly, the invention is directed to the site-selective modification of nucleic acids with electron transfer moieties and electrodes to produce a new class of biomaterials, and to methods of making and using them.

Owner:ROCHE MOLECULAR SYST INC +1

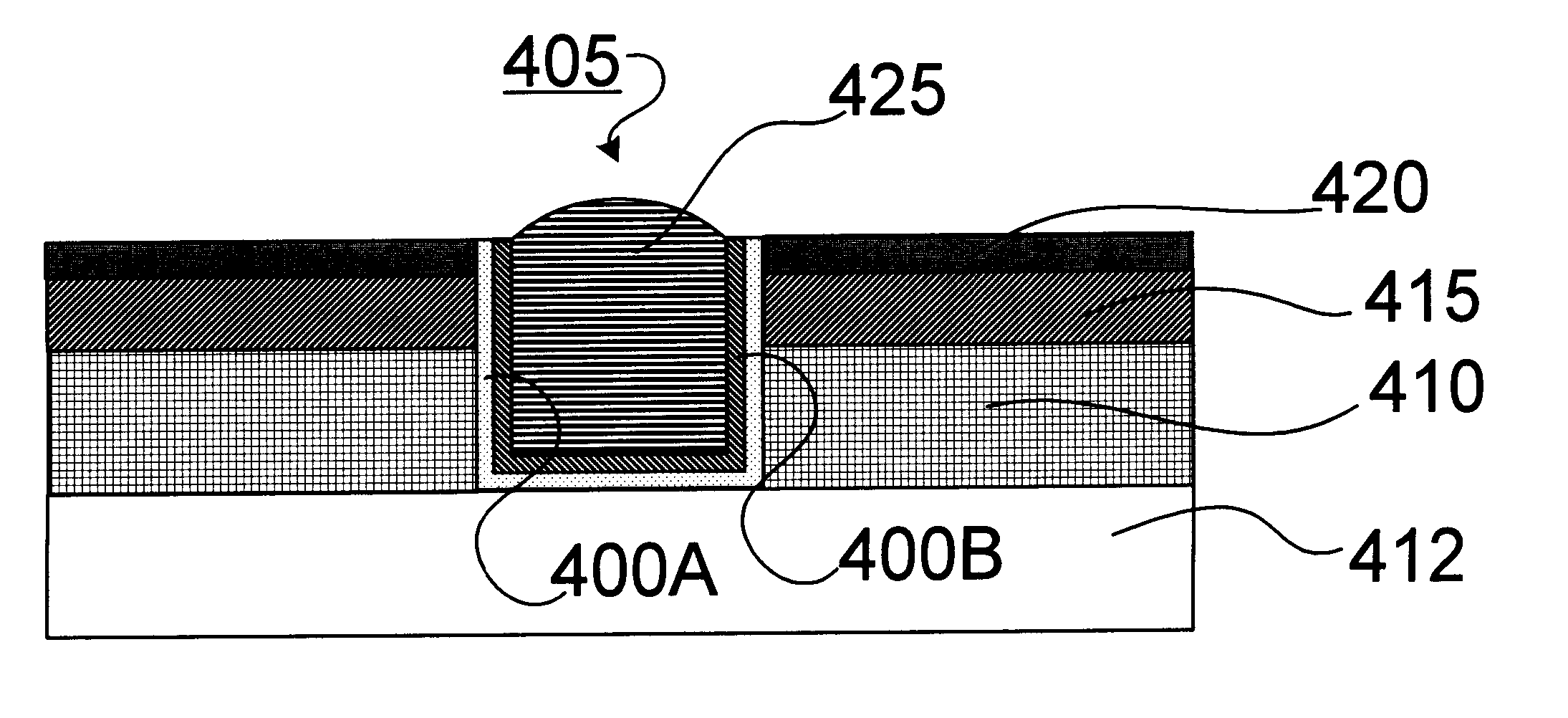

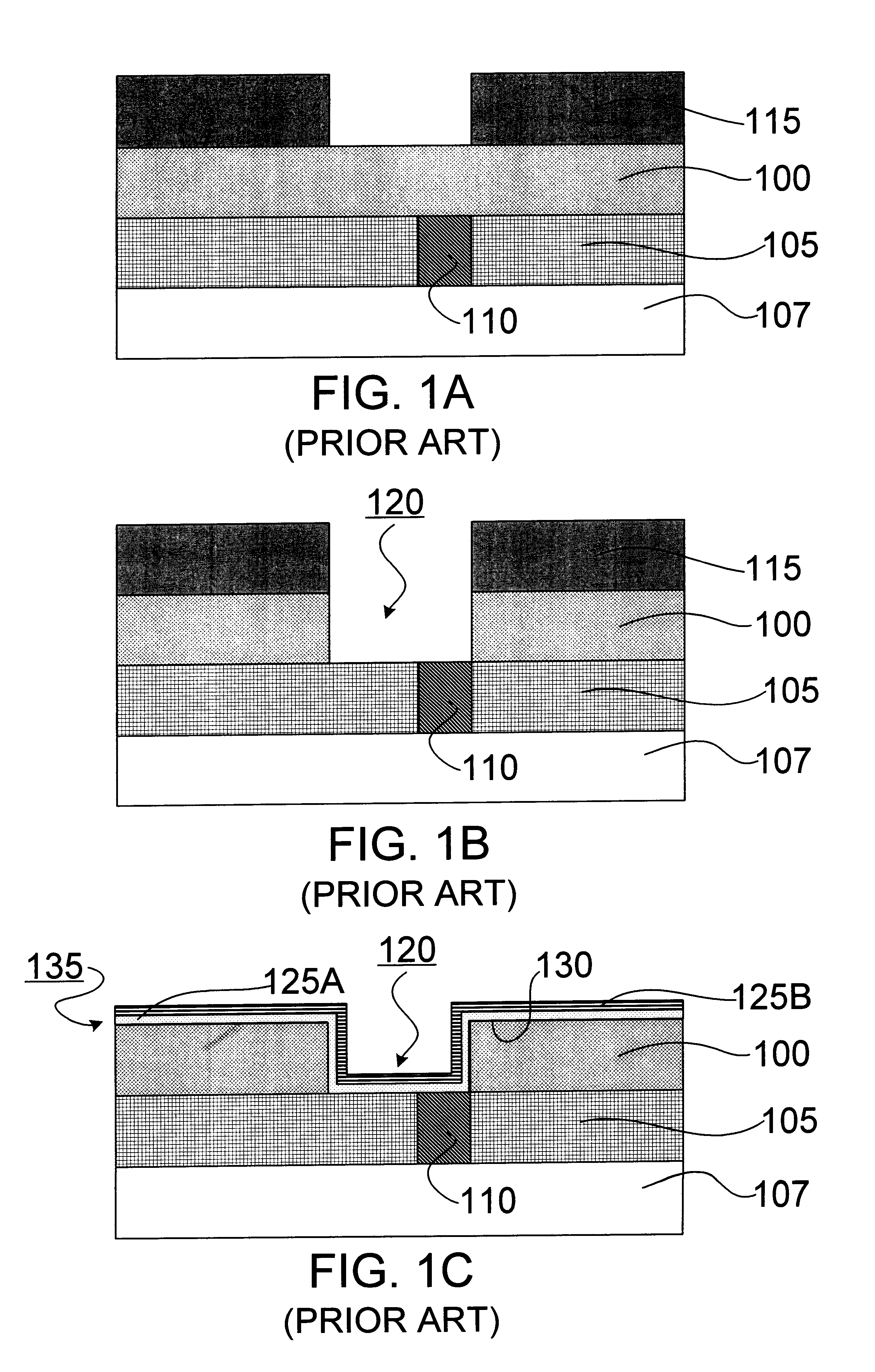

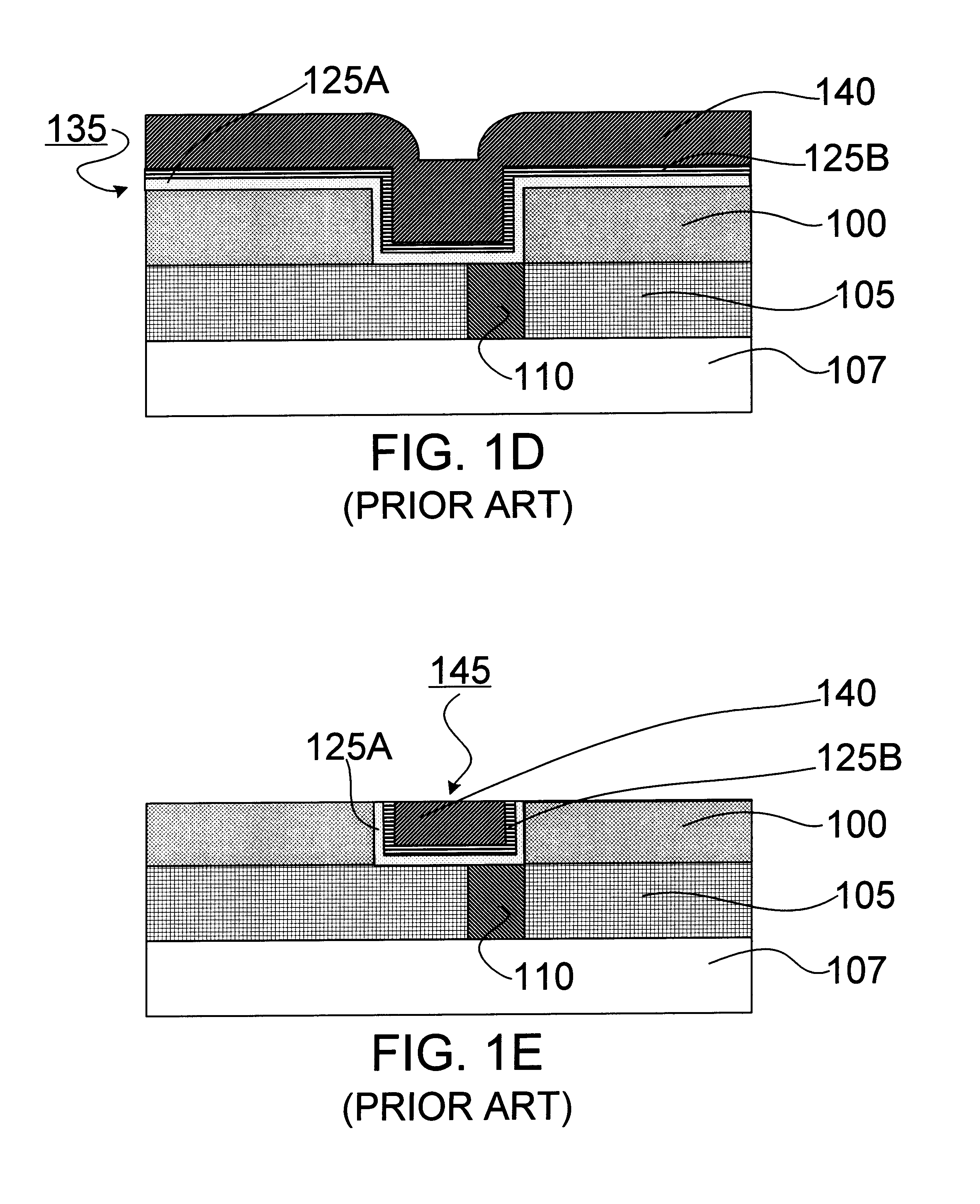

Site-selective electrochemical deposition of copper

InactiveUS6168704B1Semiconductor/solid-state device manufacturingPrinted circuit manufactureOptoelectronicsCopper

A method is provided for selectively electrochemically depositing copper. The method includes forming a layer of dielectric material above a structure layer, forming a conductive layer above the layer of dielectric material and forming an opening in the conductive layer and the layer of dielectric material. The method also includes selectively forming at least one barrier metal layer and a copper seed layer only in the opening, the at least one barrier metal layer and the copper seed layer being conductively coupled to the conductive layer. The method further includes forming an insulating layer above the conductive layer, and selectively electrochemically depositing copper only in the opening.

Owner:ADVANCED MICRO DEVICES INC

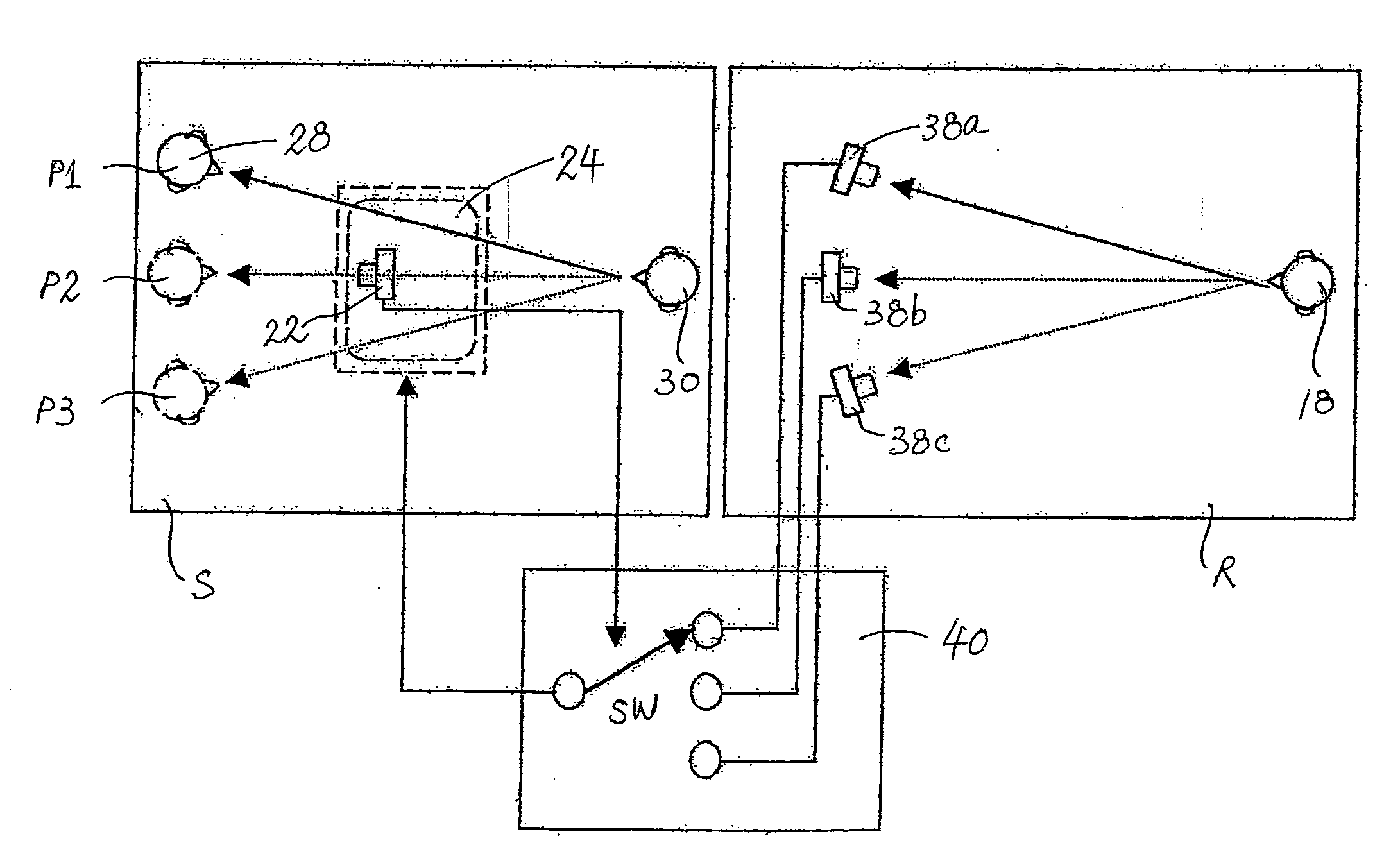

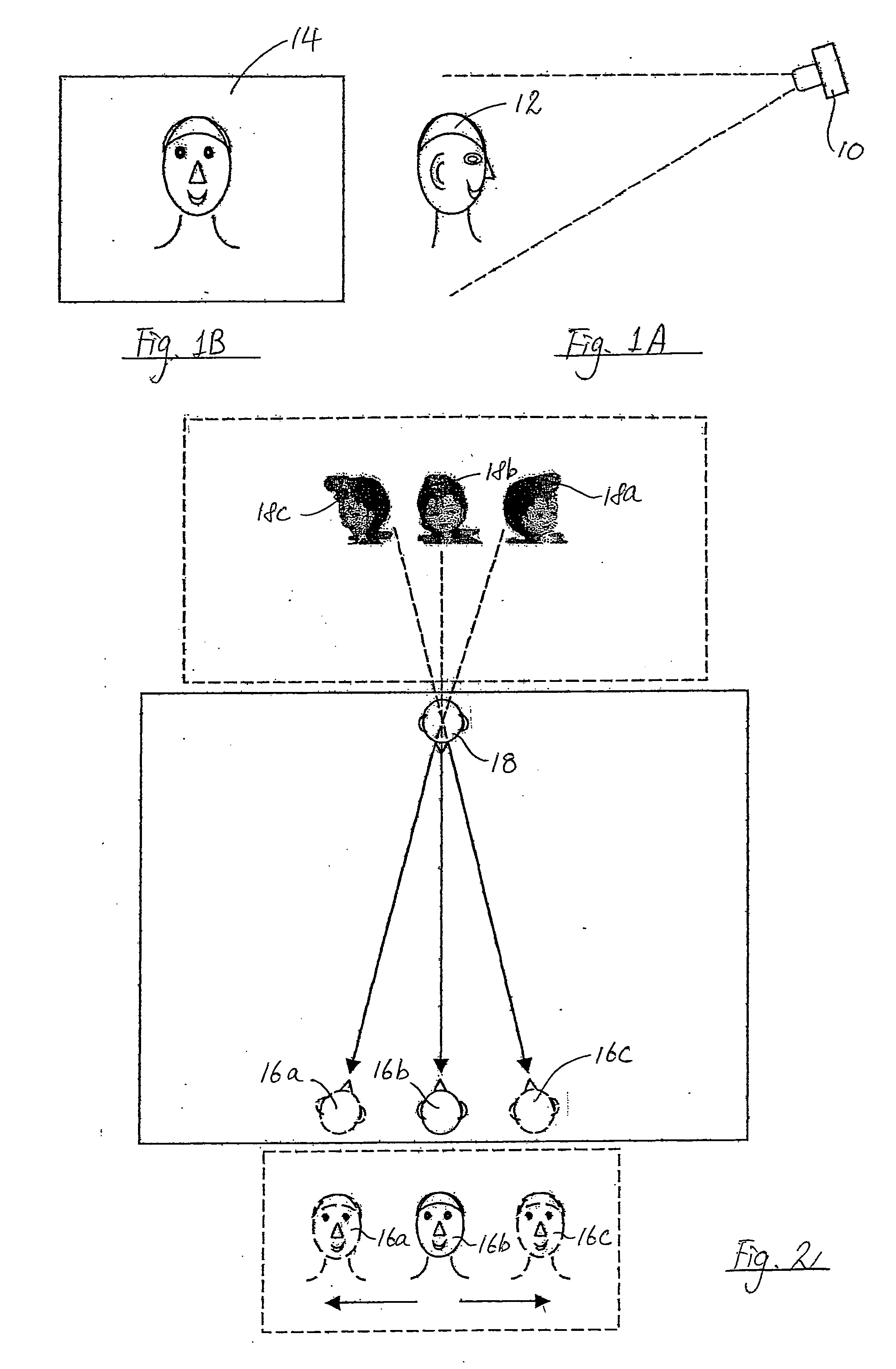

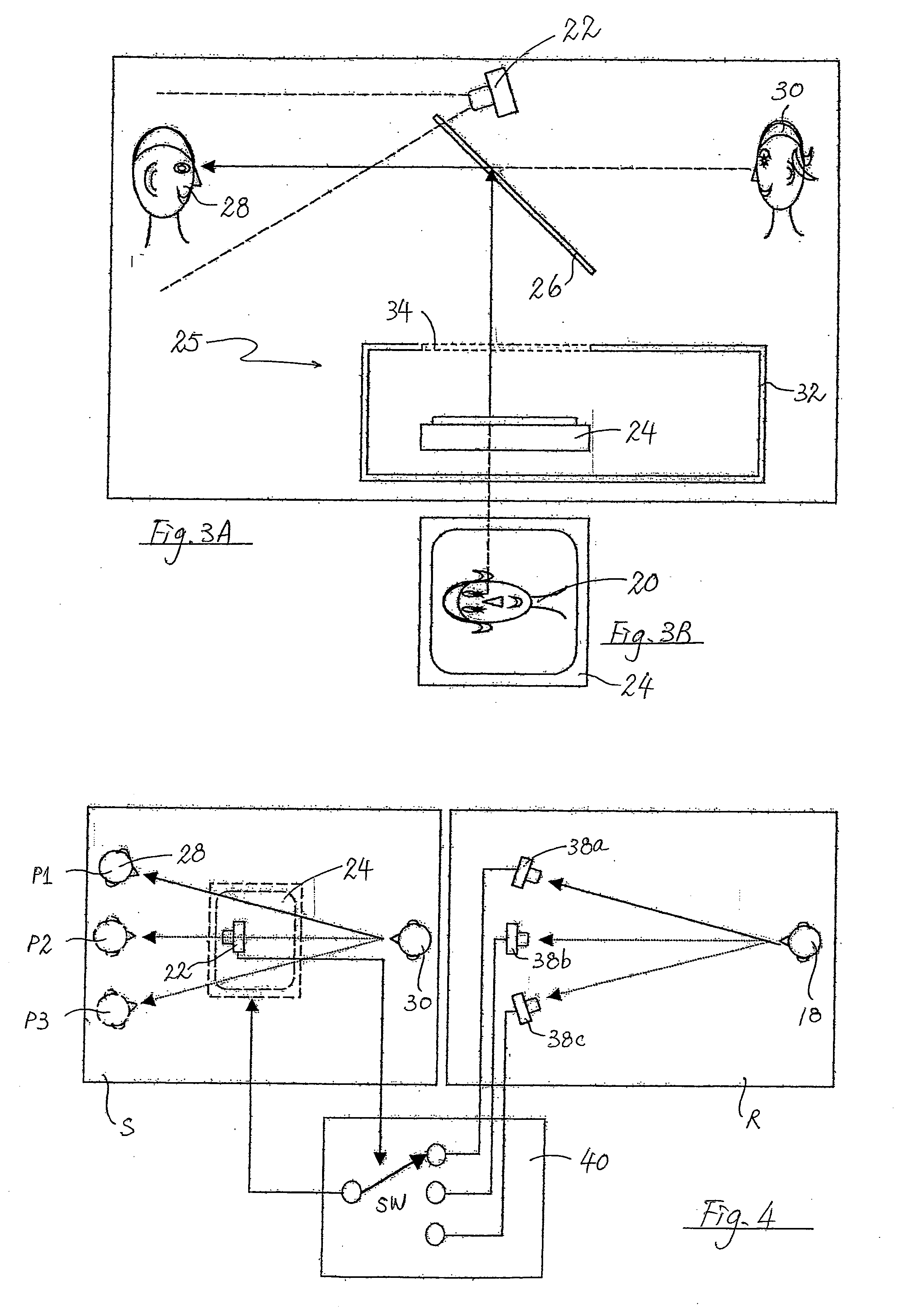

Display system and method

InactiveUS20060274031A1Cathode-ray tube indicatorsTwo-way working systemsDigital videoComputer graphics (images)

A display system is disclosed as including first and second visual display units (VDU's), each for displaying visual images for viewing; a first digital video camera for capturing images of a first individual viewing images displayed by the first VDU; at least second and third digital video cameras for capturing, each from a different angle, images of a second individual viewing the second VDU; in which the first digital video camera is connectable with the second VDU for transmitting the captured images to the second VDU for display; and the first VDU is connectable with either of the second and third digital video cameras for display of images captured by either of the second and third digital video cameras; means for identifying the position of the centre point between the eyes of the captured images of the first individual against a capture window of the first digital video camera; and means for selectively connecting the first VDU with the second digital video camera or the third digital video camera in accordance with the identified position of the centre point between the eyes of the first individual. A visual display apparatus is also disclosed as including a visual display unit supported by a table, the table including a closable opening; a reflector movable relative to the table between a first position in which the reflector closes the opening and a second position in which the opening is open and images displayed by the visual display unit are reflectable by the reflector for viewing; and an end of the reflector is slidably and swivellably movable relative to the table for movement between the first and second positions.

Owner:YUEN LAU CHAN

Method and apparatus for controlling friction between a fluid and a body

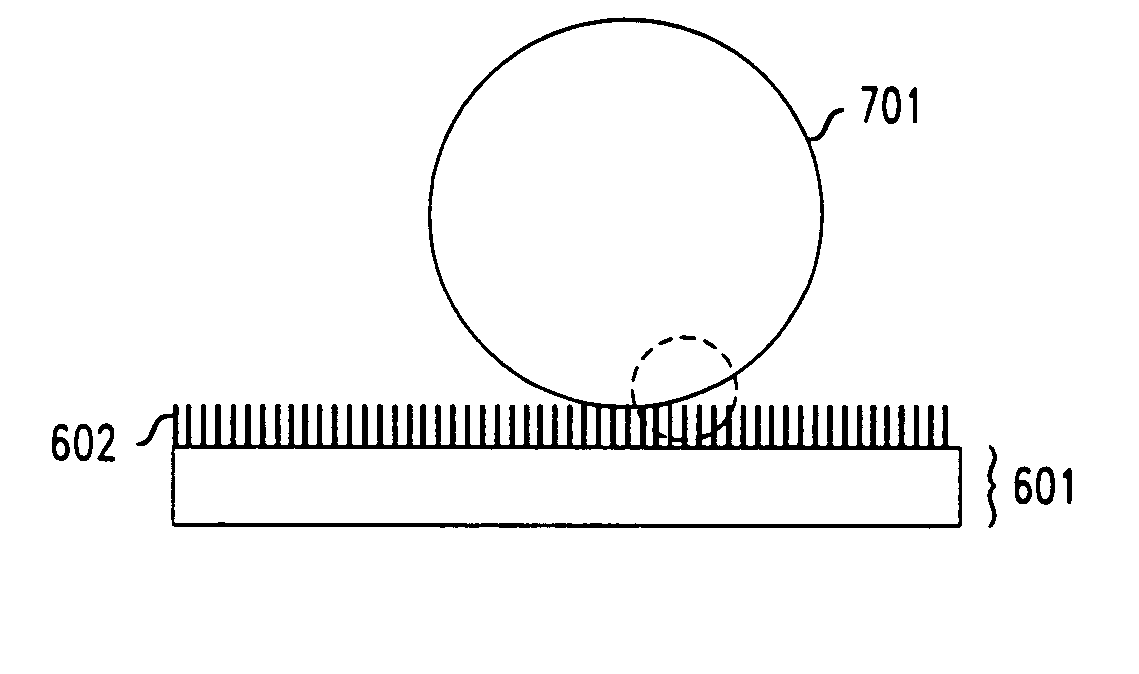

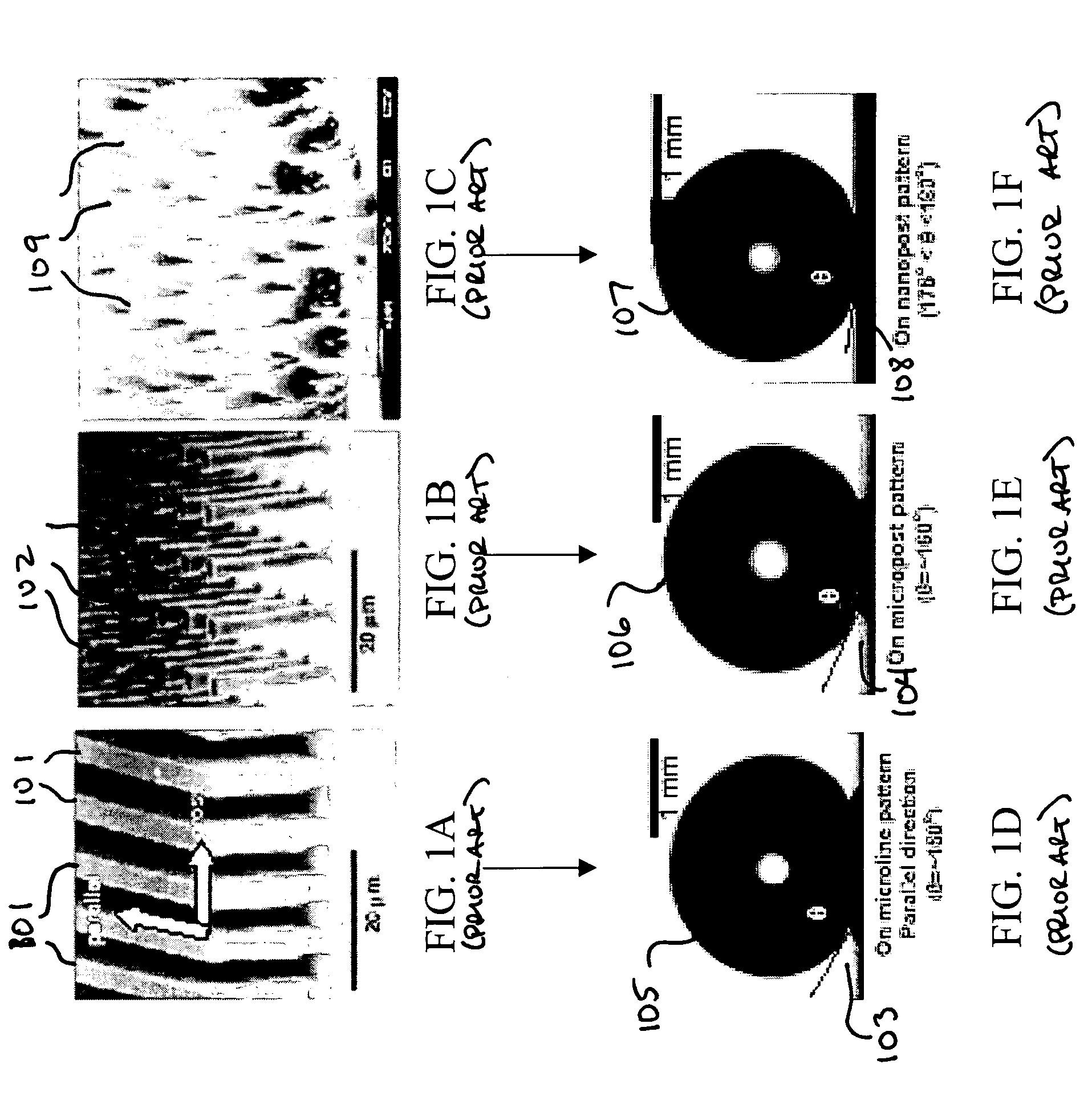

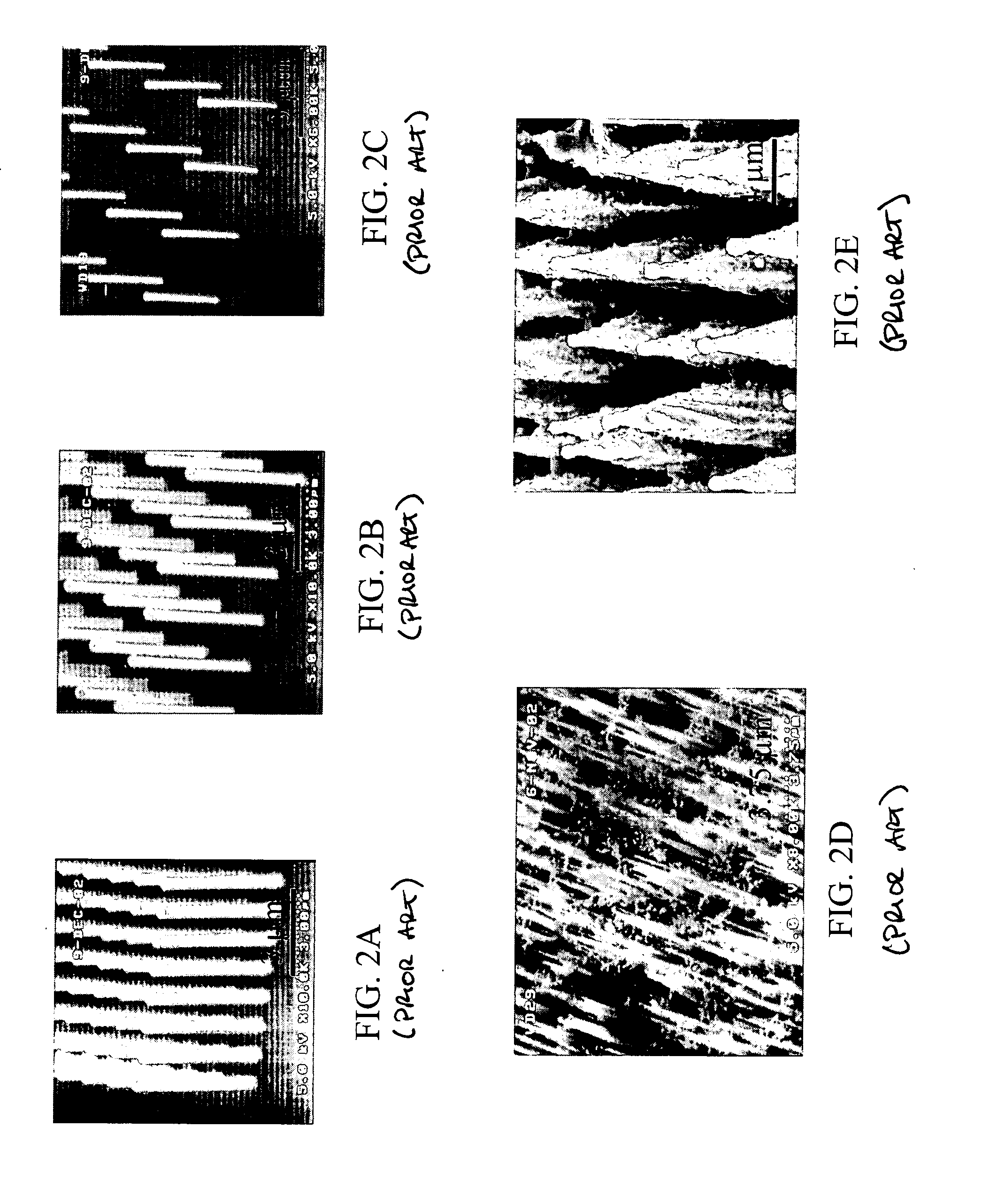

InactiveUS20050039661A1Minimizing detrimental drag effect of frictionReduce frictionRotary propellersWatercraft hull designElectricityNanostructure

A method and apparatus is disclosed wherein nanostructures or microstructures are disposed on a surface of a body (such as a submersible vehicle) that is adapted to move through a fluid, such as water. The nanostructures or microstructures are disposed on the surface in a way such that the contact between the surface and the fluid is reduced and, correspondingly, the friction between the surface and the fluid is reduced. In an illustrative embodiment, the surface is a surface on a submarine or other submersible vehicle (such as a torpedo). Illustratively, electrowetting principles are used to cause the fluid to at least partially penetrate the nanostructures or microstructures on the surface of the body in order to selectively create greater friction in a desired location of the surface. Such penetration may be used, for example, to create drag that alters the direction or speed of travel of the body.

Owner:WSOU INVESTMENTS LLC +1

AC/DC voltage apparatus for detection of nucleic acids

InactiveUS7381525B1Bioreactor/fermenter combinationsBiological substance pretreatmentsOligomerElectron transfer

The invention relates to nucleic acids covalently coupled to electrodes via conductive oligomers. More particularly, the invention is directed to the site-selective modification of nucleic acids with electron transfer moieties and electrodes to produce a new class of biomaterials, and to methods of making and using them.

Owner:CLINICAL MICRO SENSORS +2

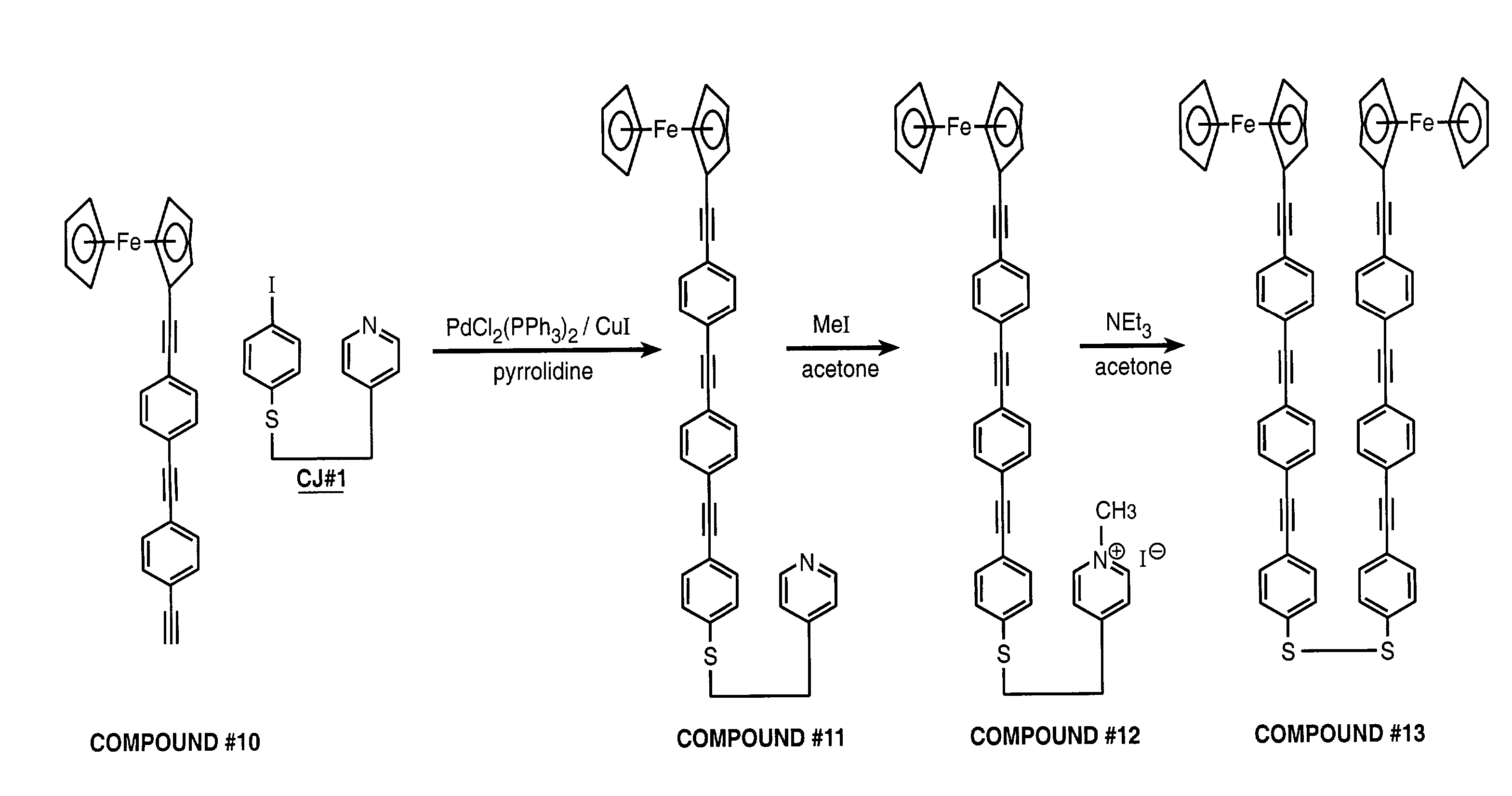

Electrodes linked via conductive oligomers to nucleic acids

InactiveUS7125668B2Simple compositionImmobilised enzymesBioreactor/fermenter combinationsOligomerConductive polymer

The invention relates to nucleic acids covalently coupled to electrodes via conductive oligomers. More particularly, the invention is directed to the site-selective modification of nucleic acids with electron transfer moieties and electrodes to produce a new class of biomaterials, and to methods of making and using them.

Owner:OSMETECH TECH +1

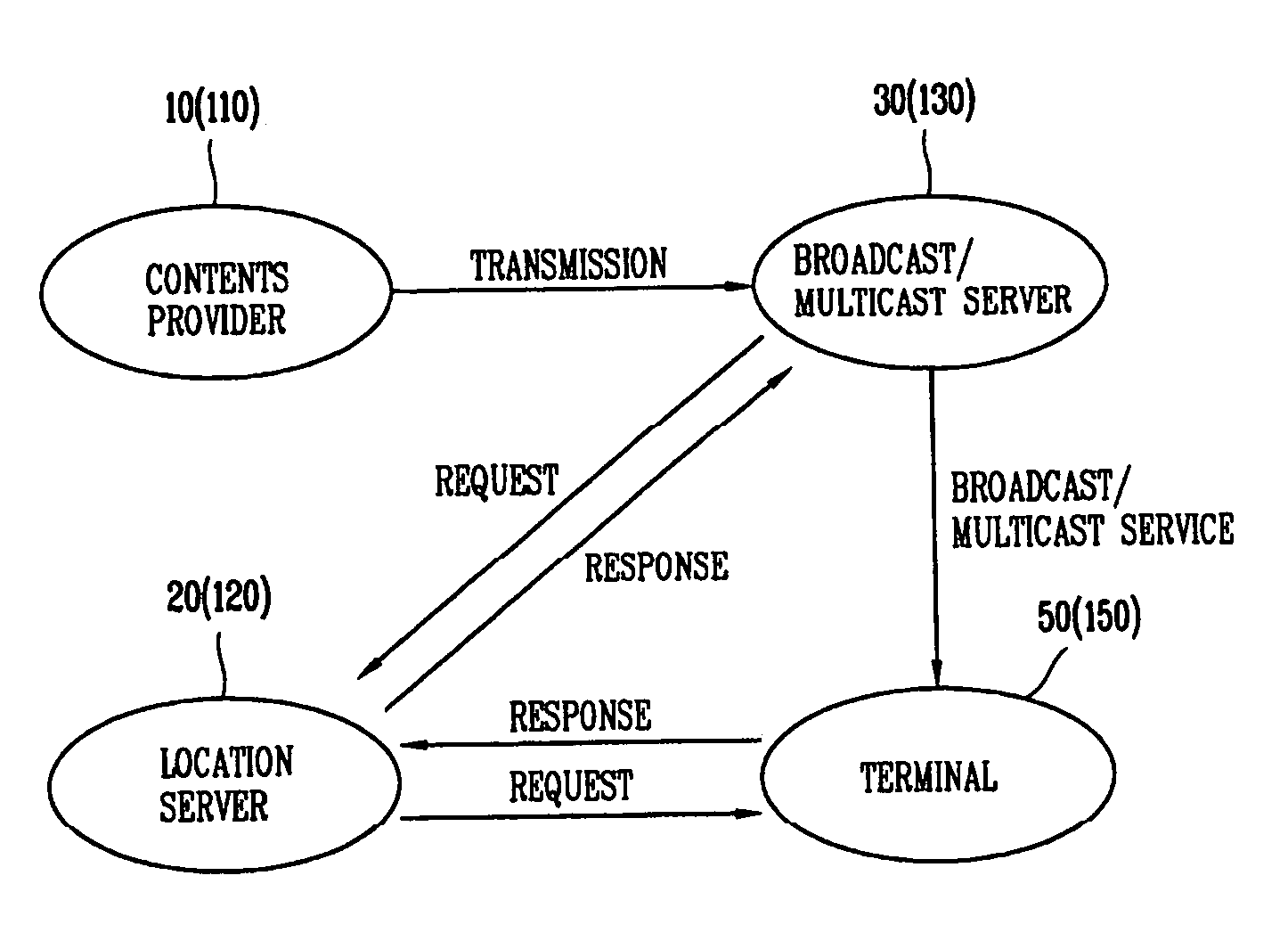

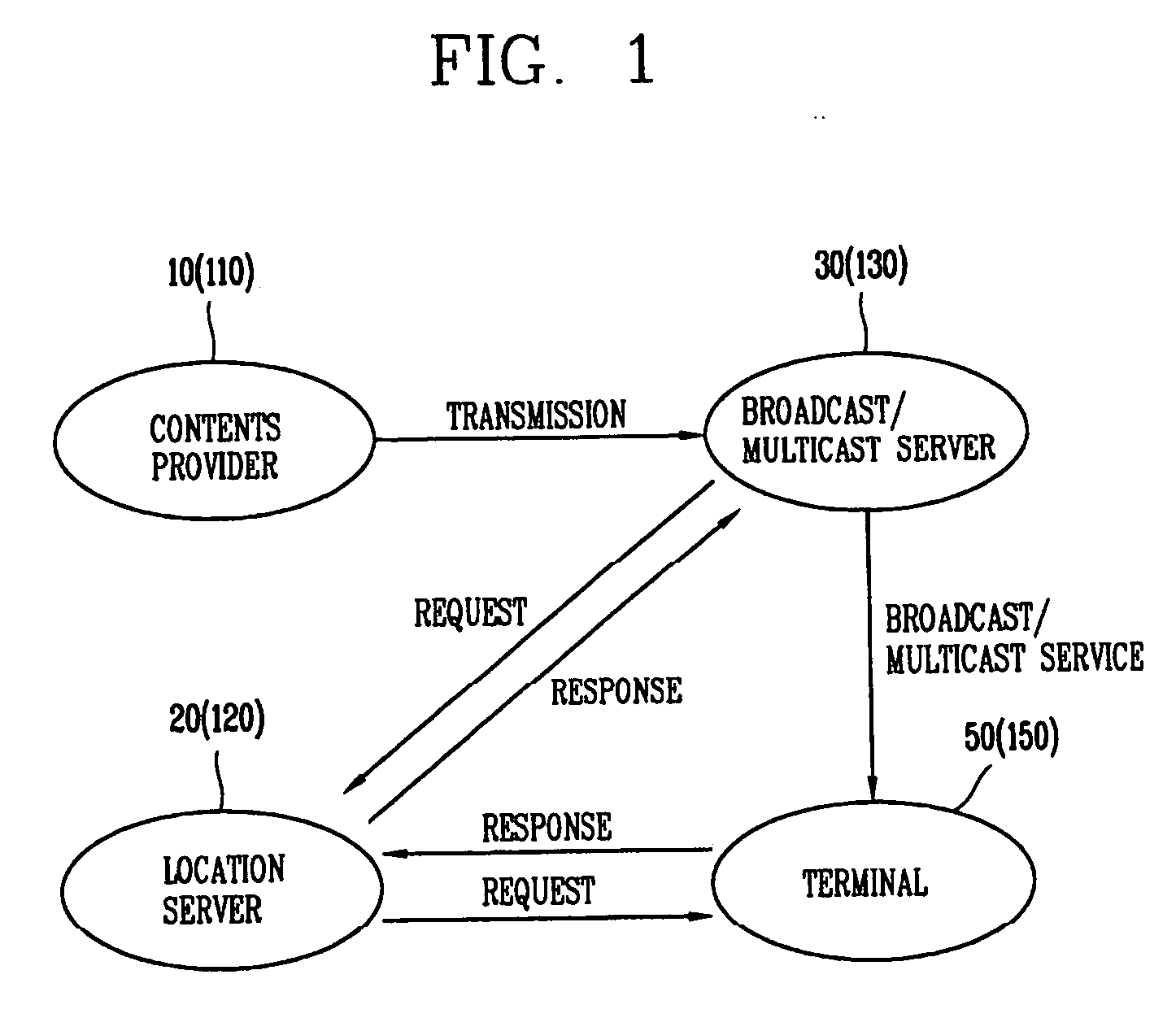

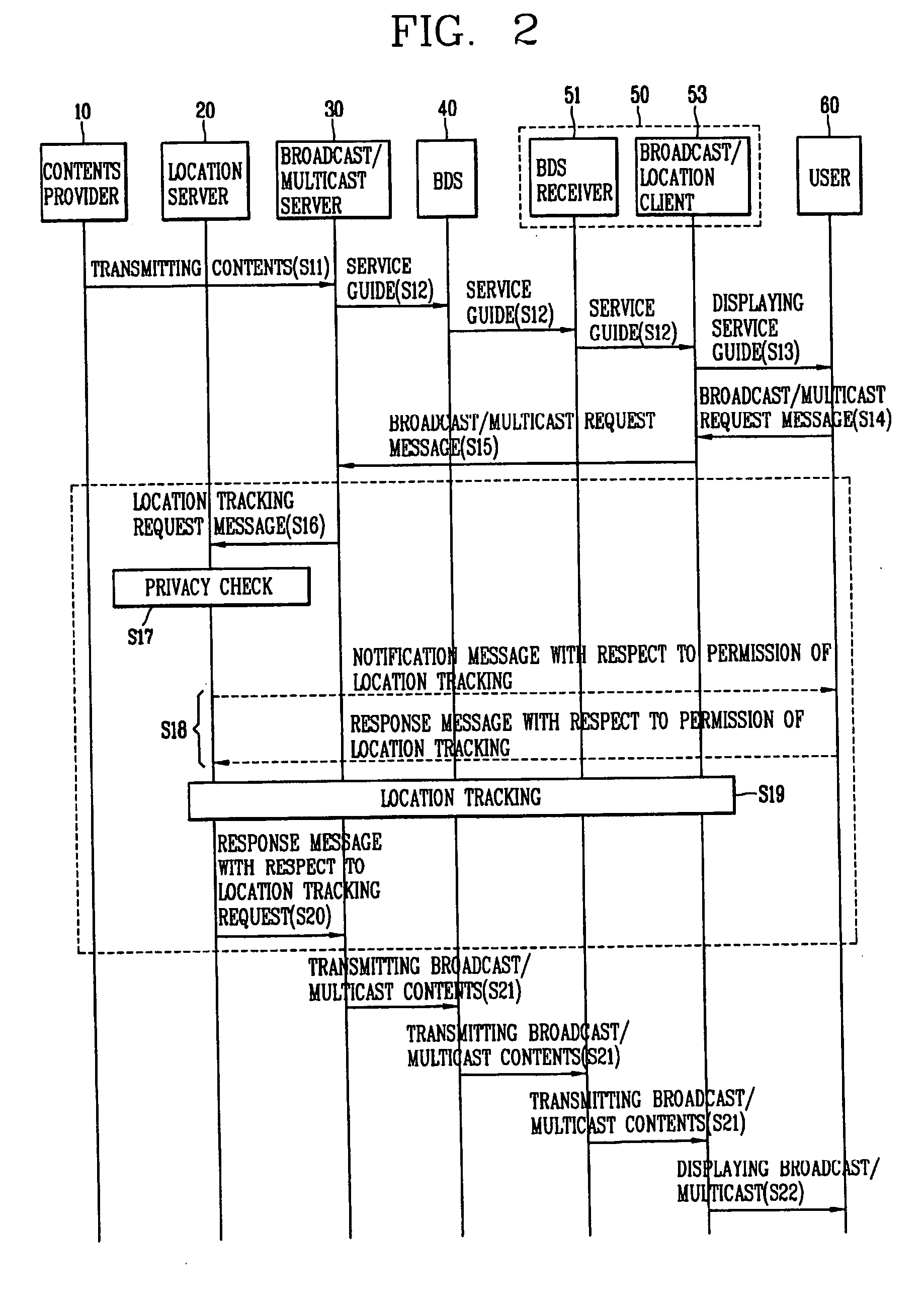

Broadcast/multicast service method based on user location information

InactiveUS20060050672A1Special service provision for substationData switching by path configurationBroadcast multicastMulticast

In a broadcast / multicast service based on user location information, when a terminal sets contents desired to be received in a specific area, a broadcast / multicast server checks current location information of the terminal transmitted from a location server or from the corresponding terminal, selects contents provided in the corresponding area, and transmits it to the terminal. Thus, a waste of a communication channel can be prevented, and since a user can selectively receive contents or information according to his / her location, user's satisfaction and convenience can be enhanced.

Owner:LG ELECTRONICS INC

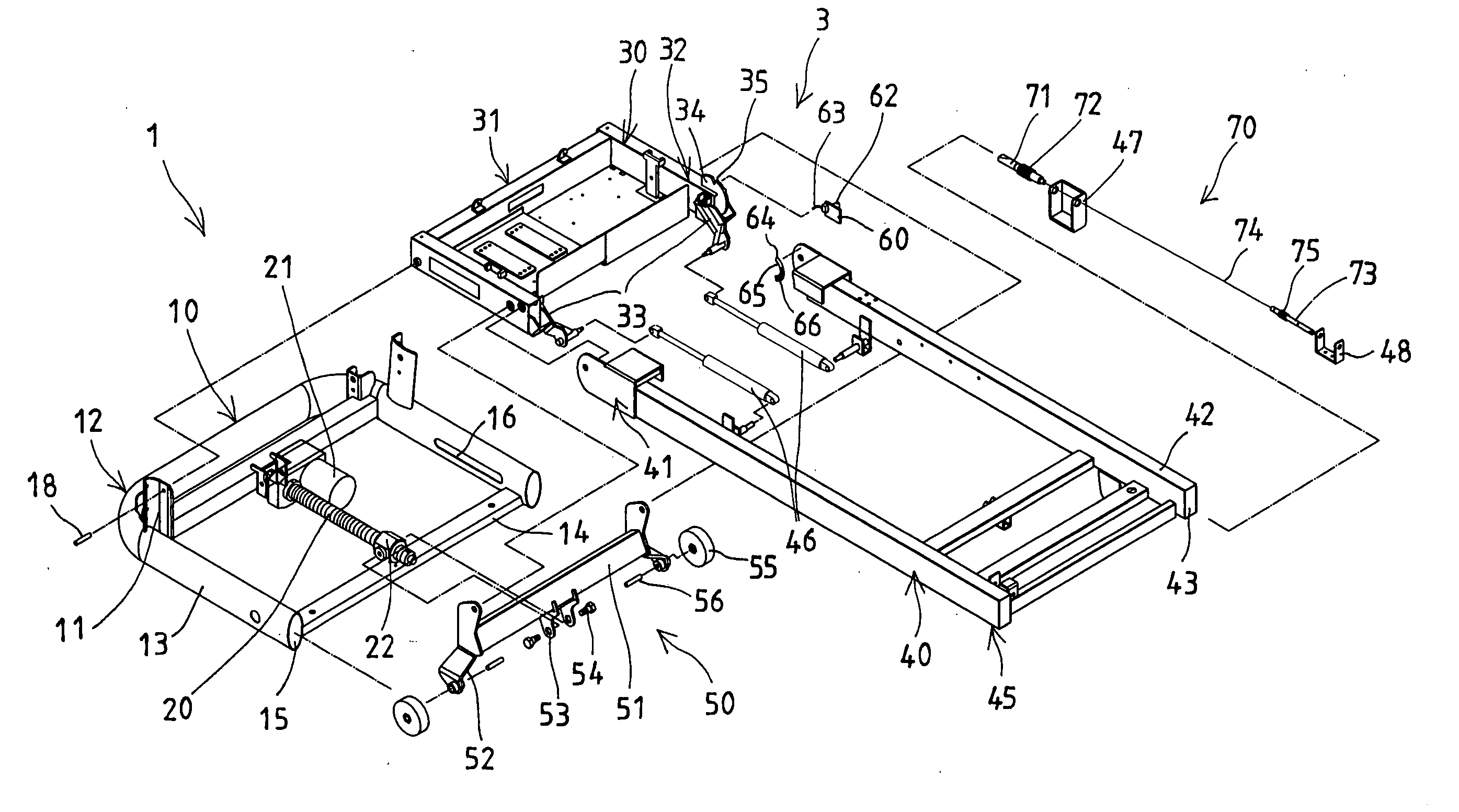

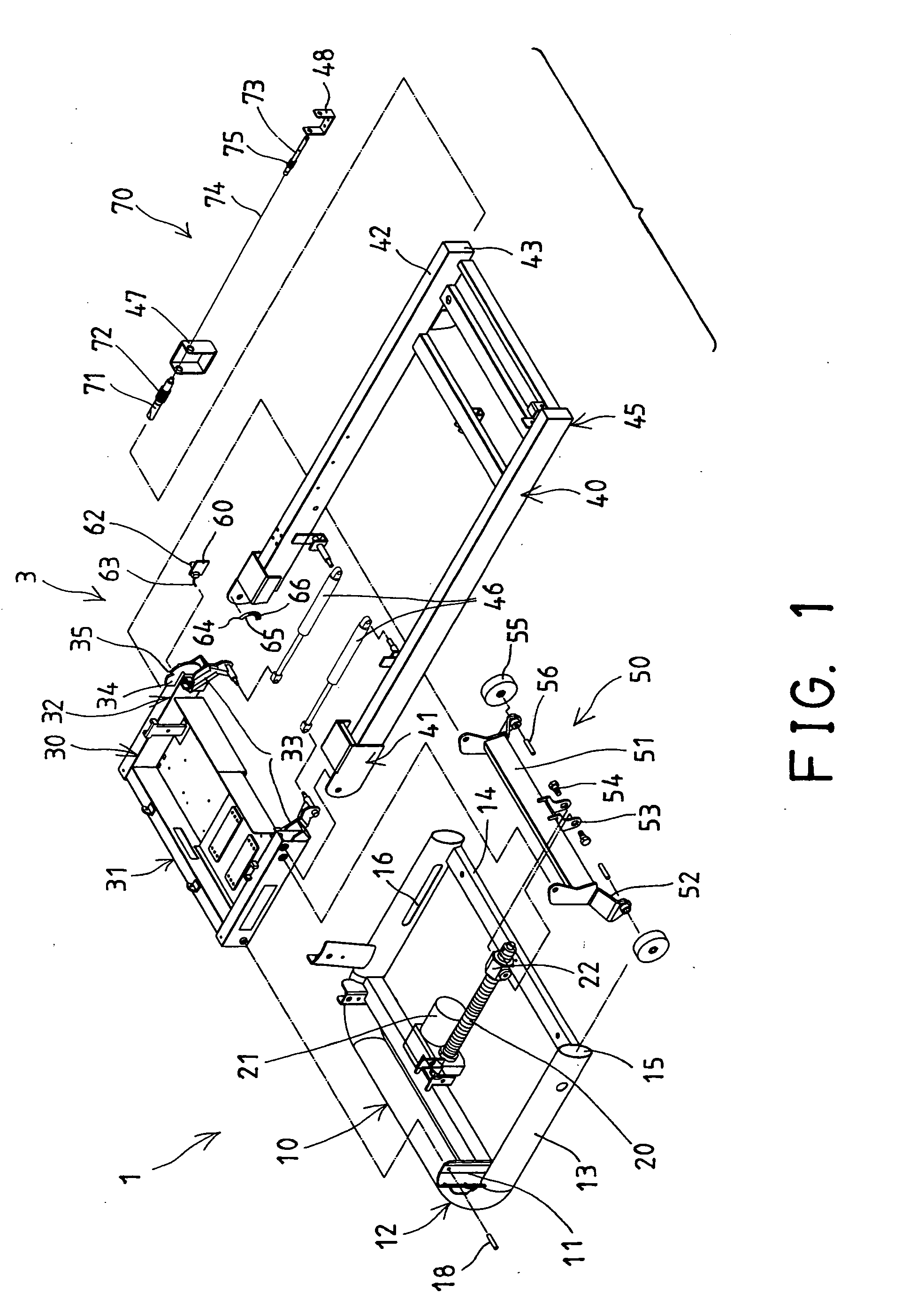

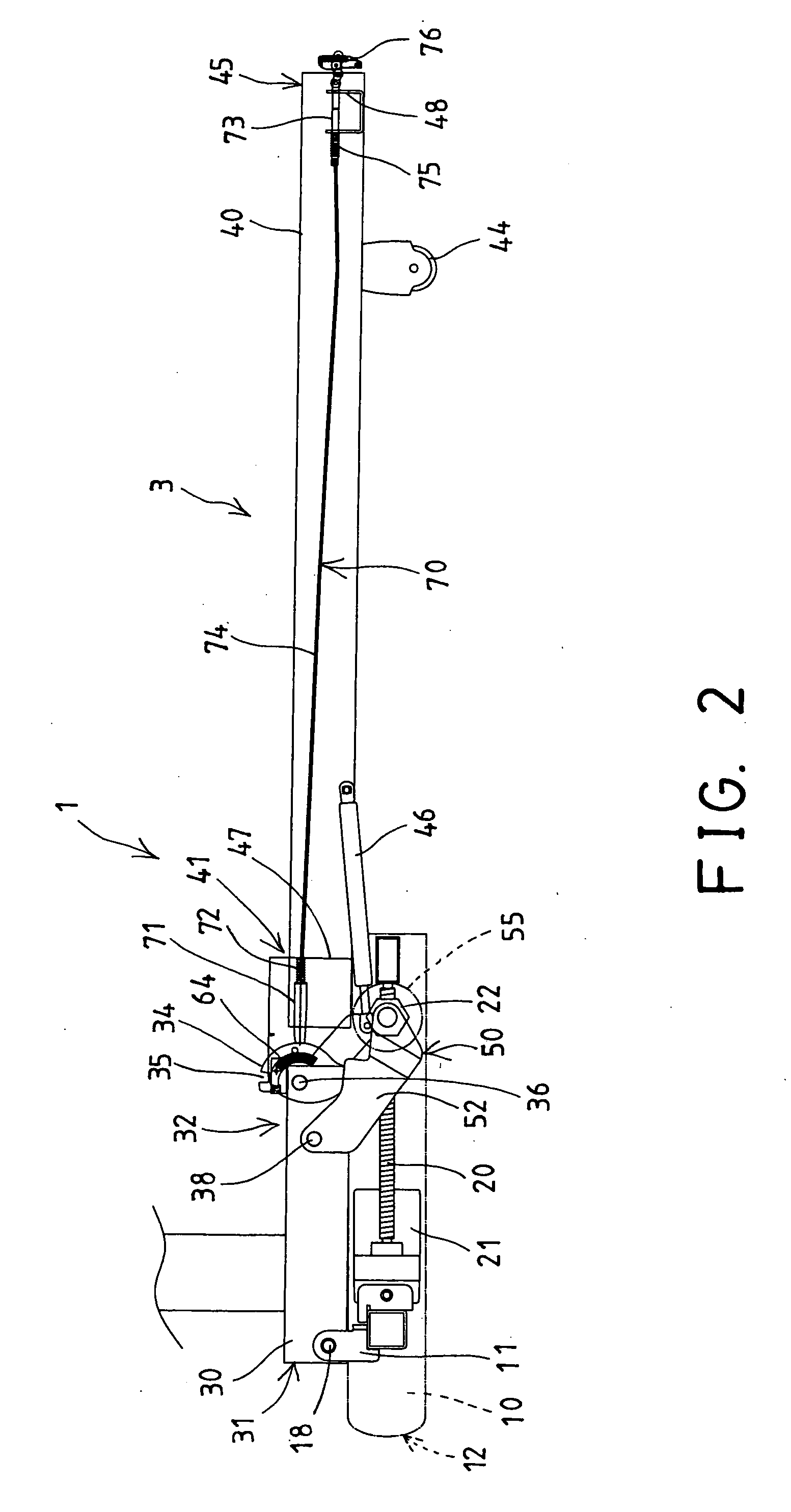

Foldable treadmill

InactiveUS20070191190A1Easy to foldStable structureSpace saving gamesMovement coordination devicesEngineeringCarriage

A foldable treadmill includes a seat, and a two-part tread base having a front carriage pivotally attached to the seat with a pivot axle for allowing the carriage to be rotated relative to the seat, and a rear treadmill frame pivotally secured to the carriage for allowing the treadmill frame to be rotated and folded relative to the carriage, and the carriage is foldable and engageable with the seat for lowering a center of gravity of the treadmill and for preventing the treadmill from falling down when the treadmill frame is rotated and folded relative to the carriage and the seat. A spring biased latch may selectively latch the treadmill frame to the carriage at an upwardly erecting position.

Owner:KUO HAI PIN

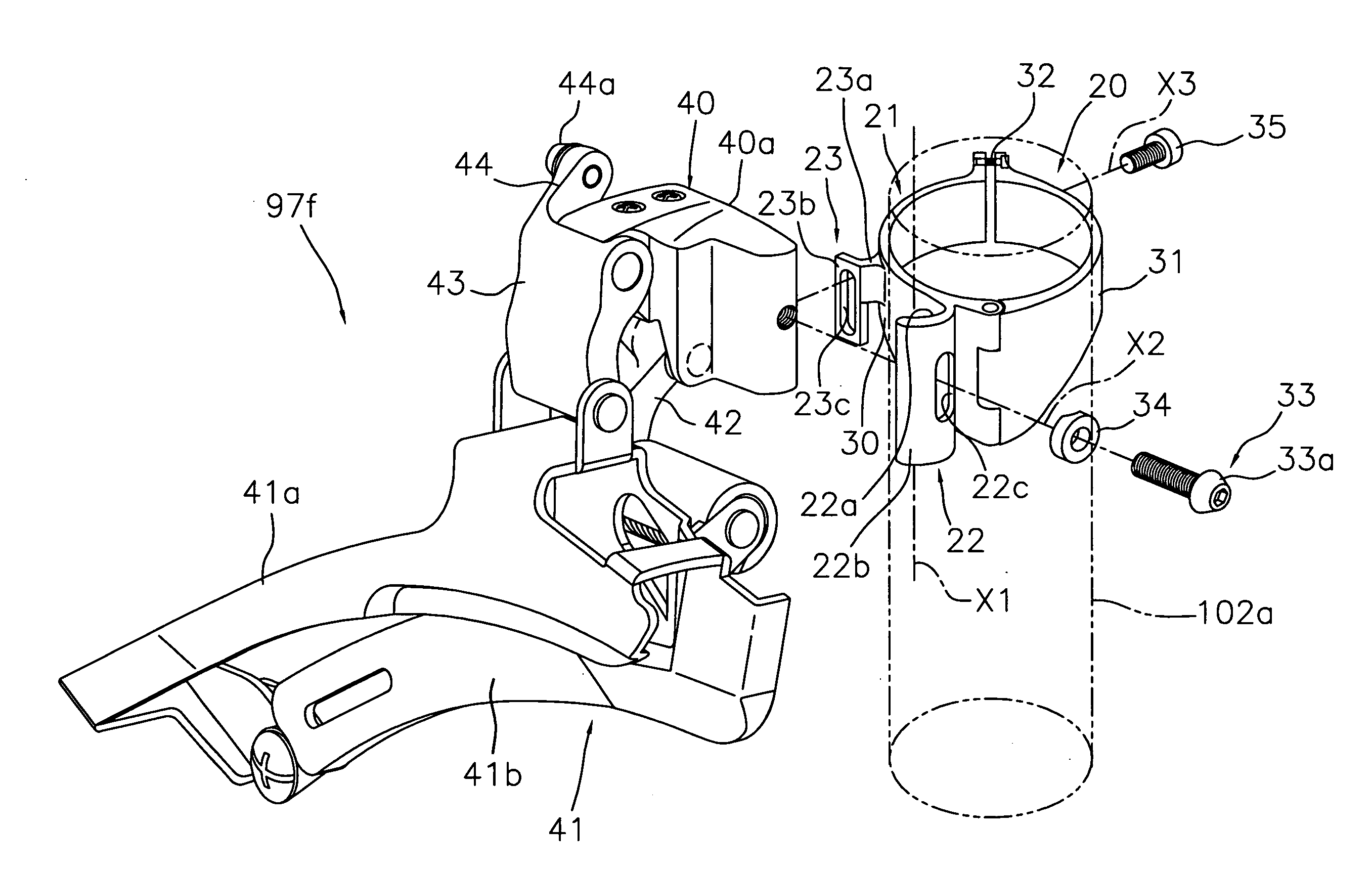

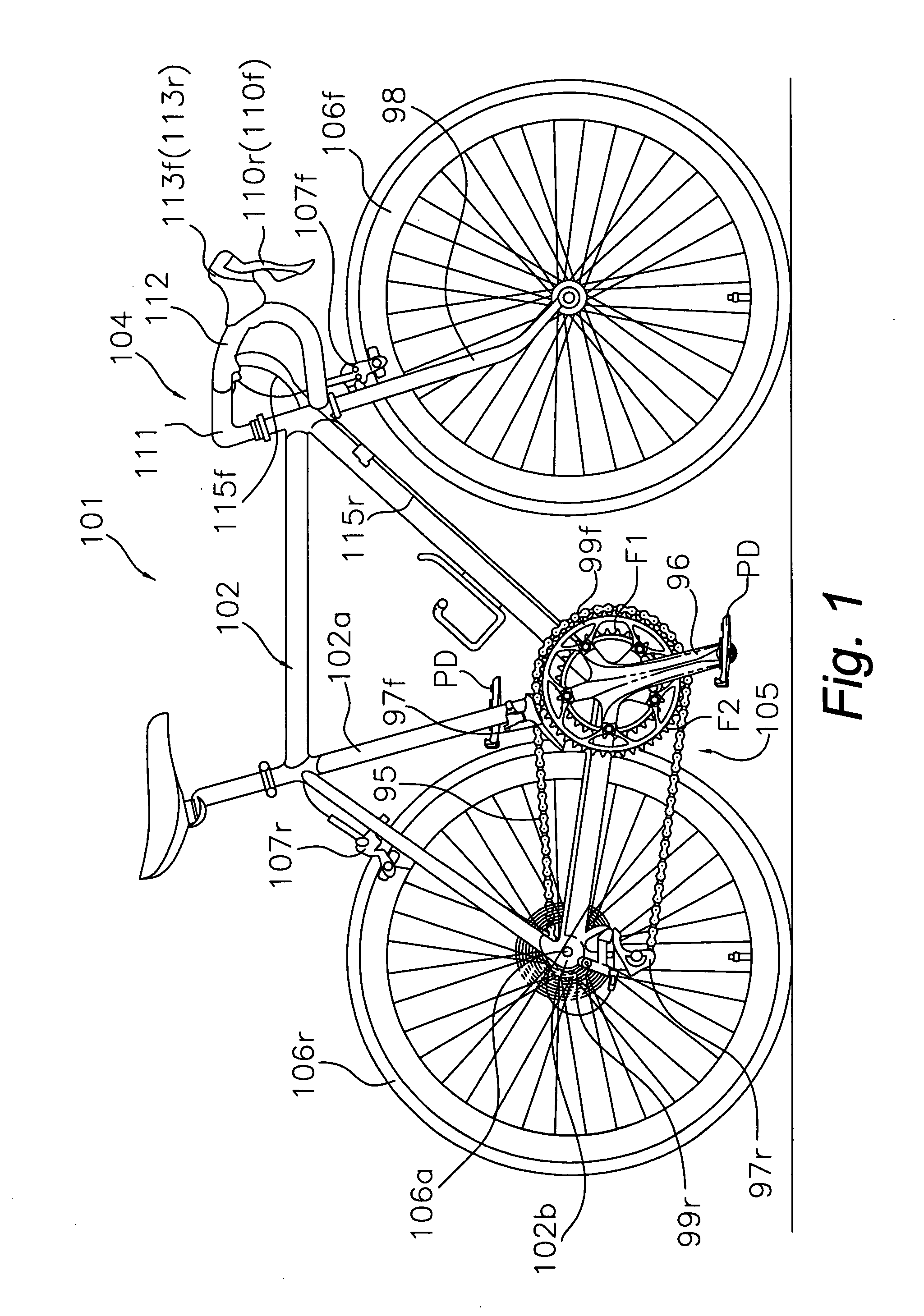

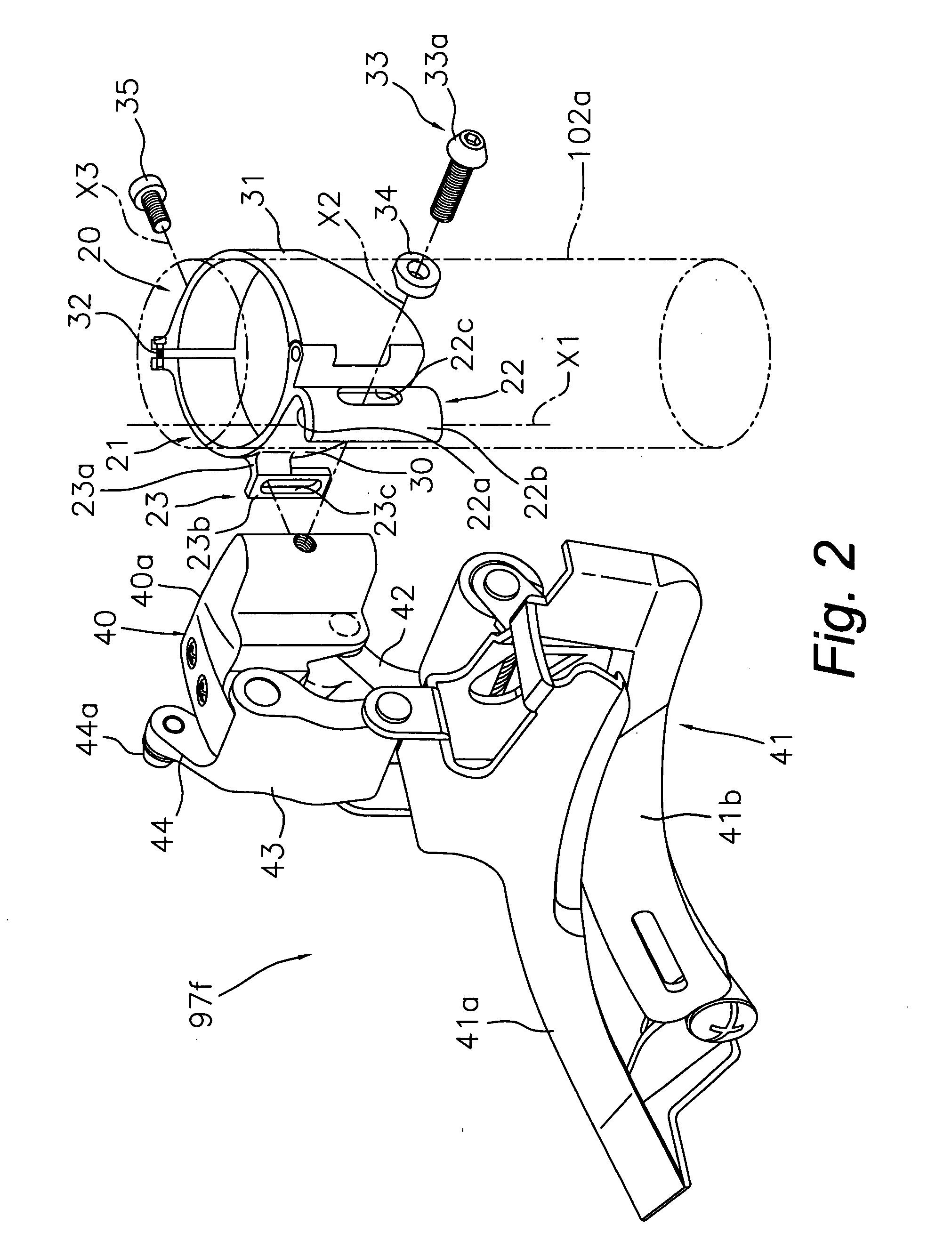

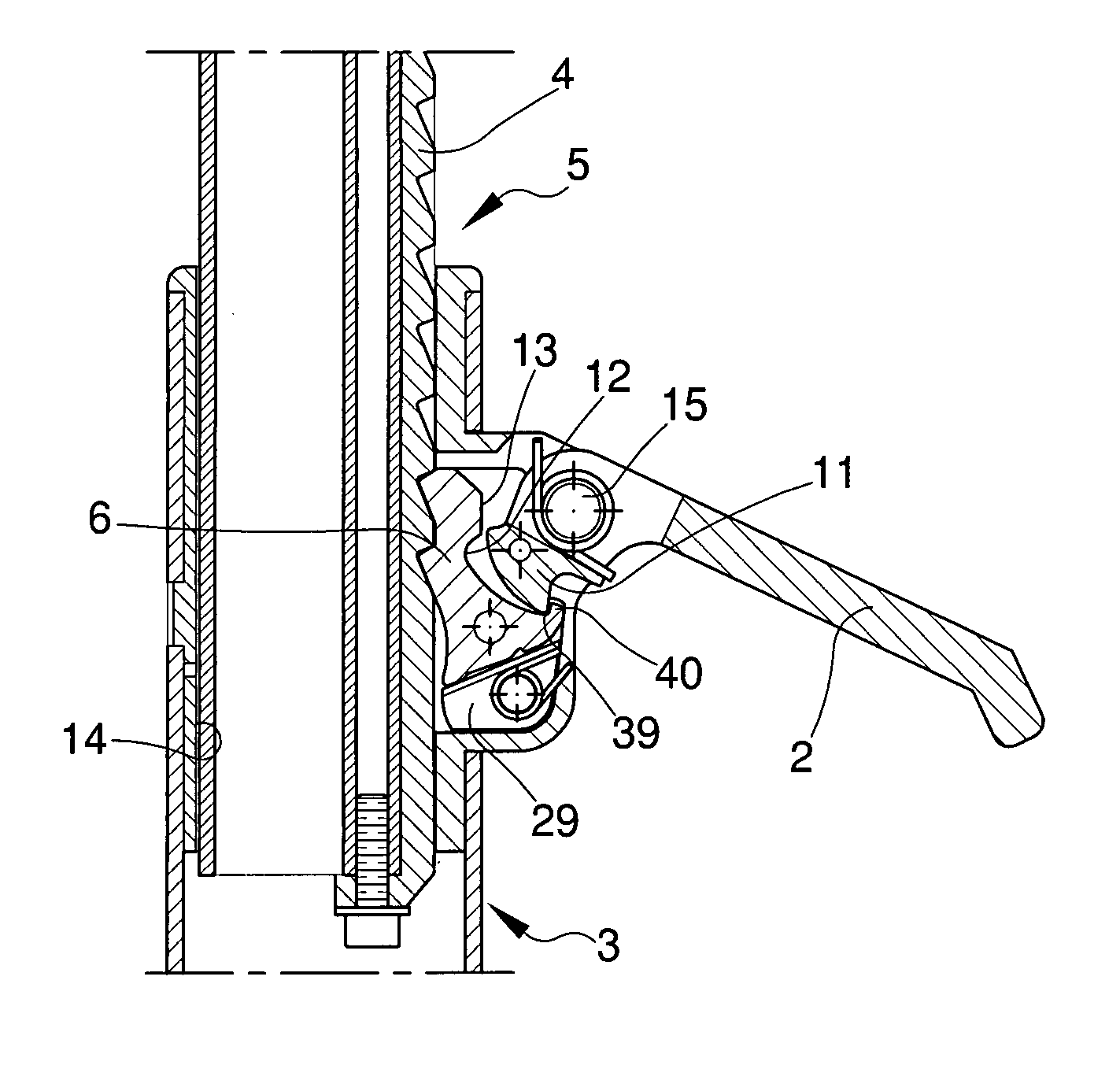

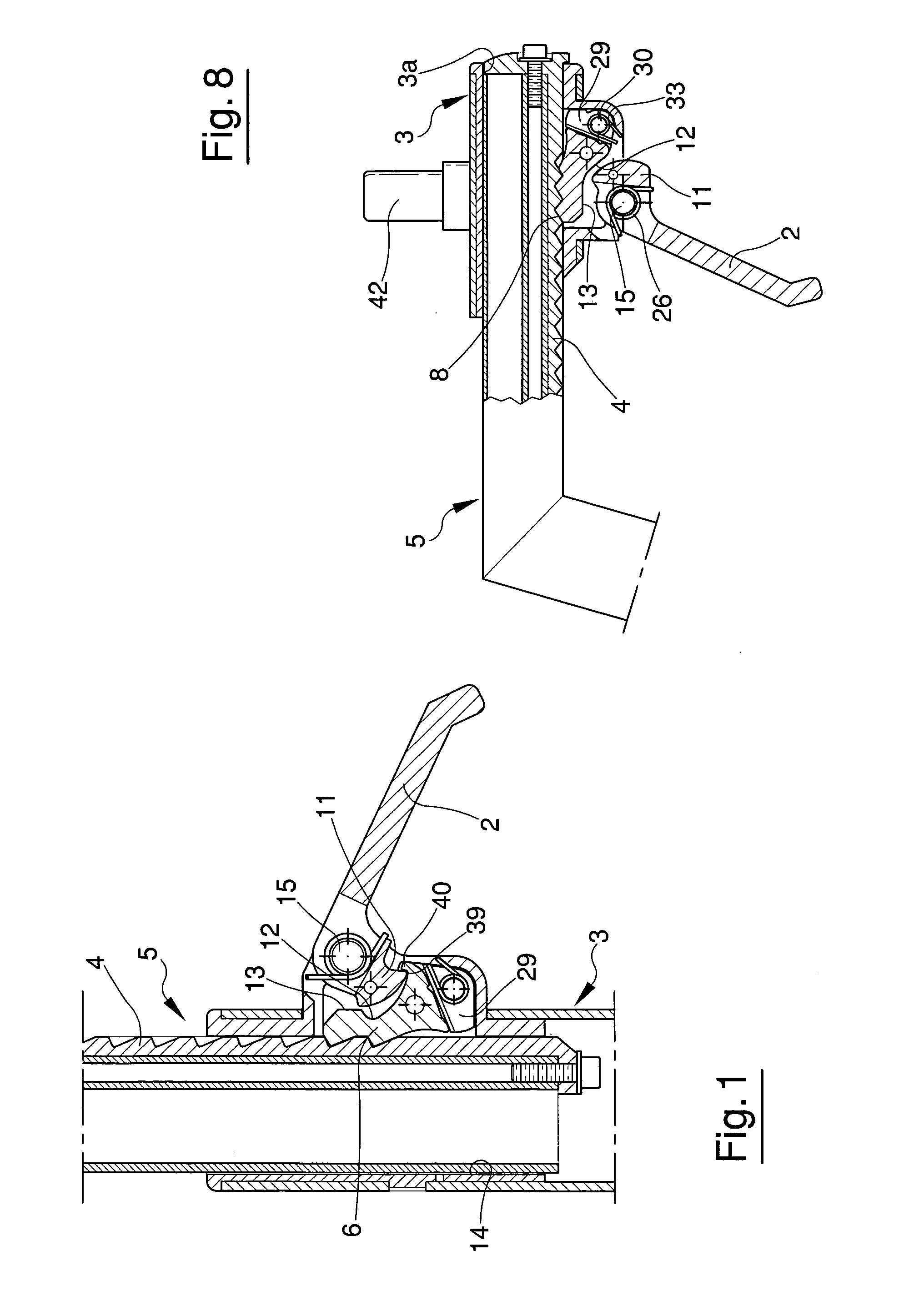

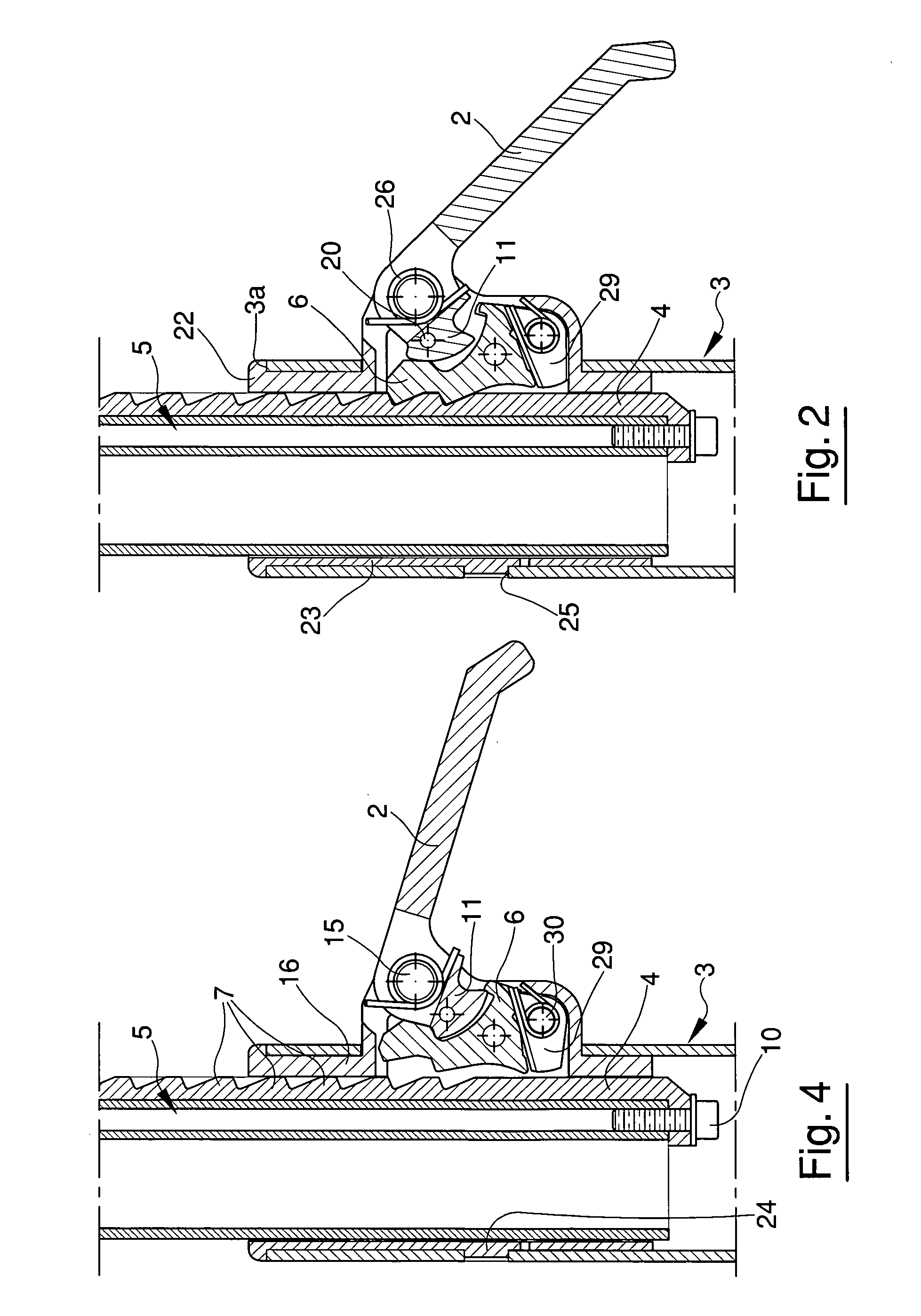

Front derailleur with mounting fixture

A bicycle front derailleur is provided with a mounting fixture that is configured to maintain an angular orientation of the front derailleur about a mounting axis parallel to a center axis of a frame tube in a stable manner. The mounting fixture has a bicycle frame fastening part, a front derailleur mounting part and a front derailleur contact part. The bicycle frame fastening part is configured to be fastened to the seat tube. The front derailleur mounting part is disposed on the bicycle frame fastening part and configured to be fastened to the front derailleur so that fine adjustment is possible about the mounting axis disposed at a distance from the seat tube. The front derailleur contact part selectively contacts a side surface of the front derailleur on the side facing the seat tube in a position that is different from that of the front derailleur mounting part.

Owner:SHIMANO INC

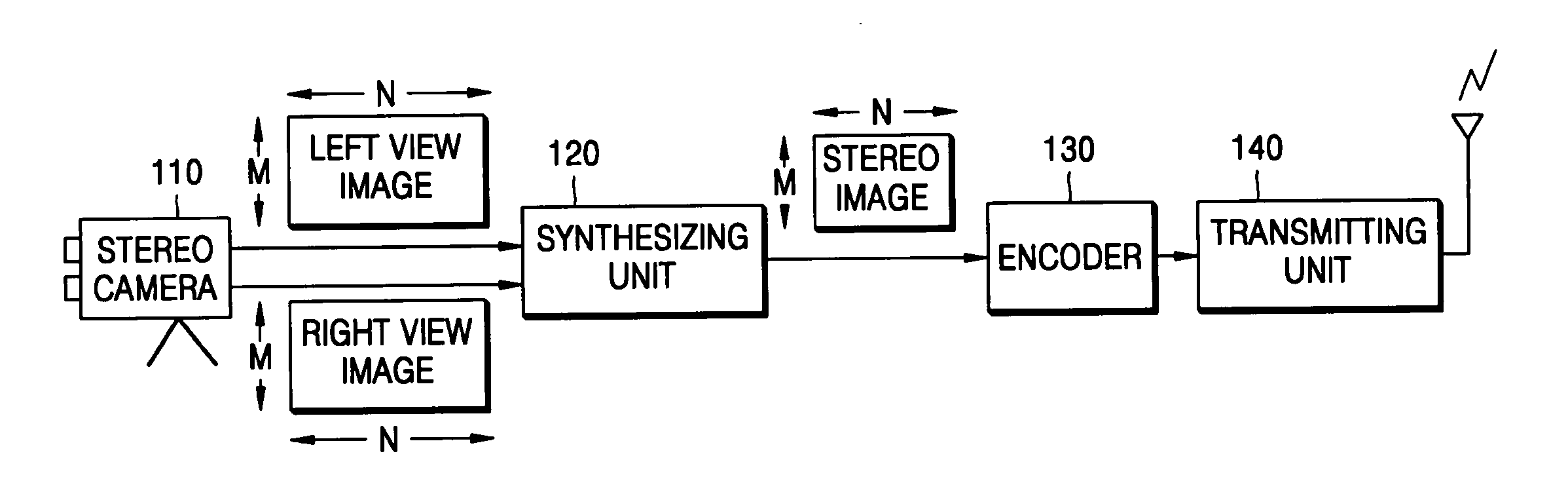

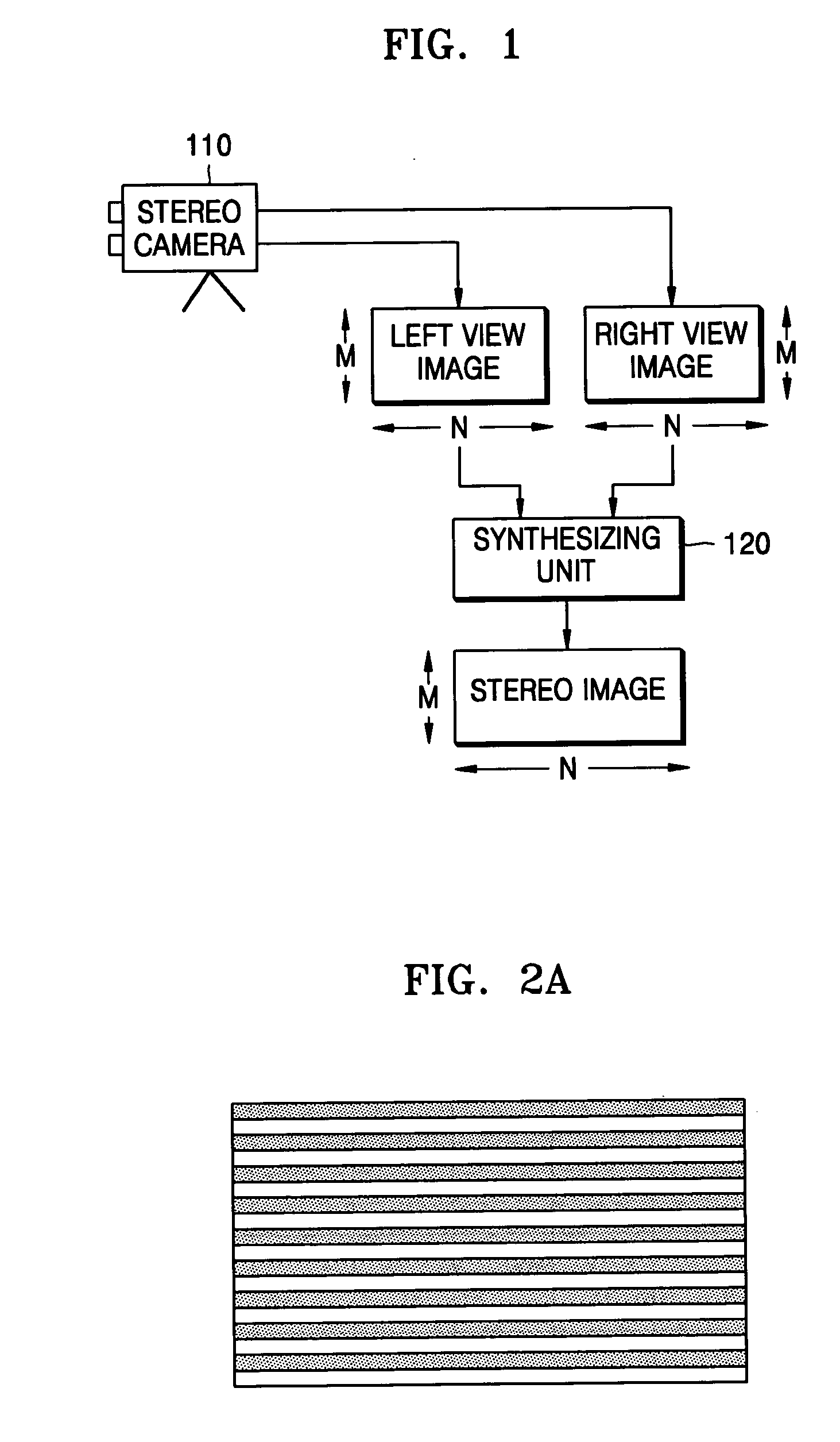

Method and apparatus for encoding and decoding stereo image

A method and apparatus are provided for encoding and decoding a stereo image through motion estimation performed in a block using a search area that is temporally or spatially separated from the block according to the position of the block. The method of encoding a stereo image includes determining the position of a block to be motion-estimated, selectively performing time domain motion estimation or spatial domain motion estimation according to the determined position, and performing motion compensation according to the result of motion estimation.

Owner:SAMSUNG ELECTRONICS CO LTD

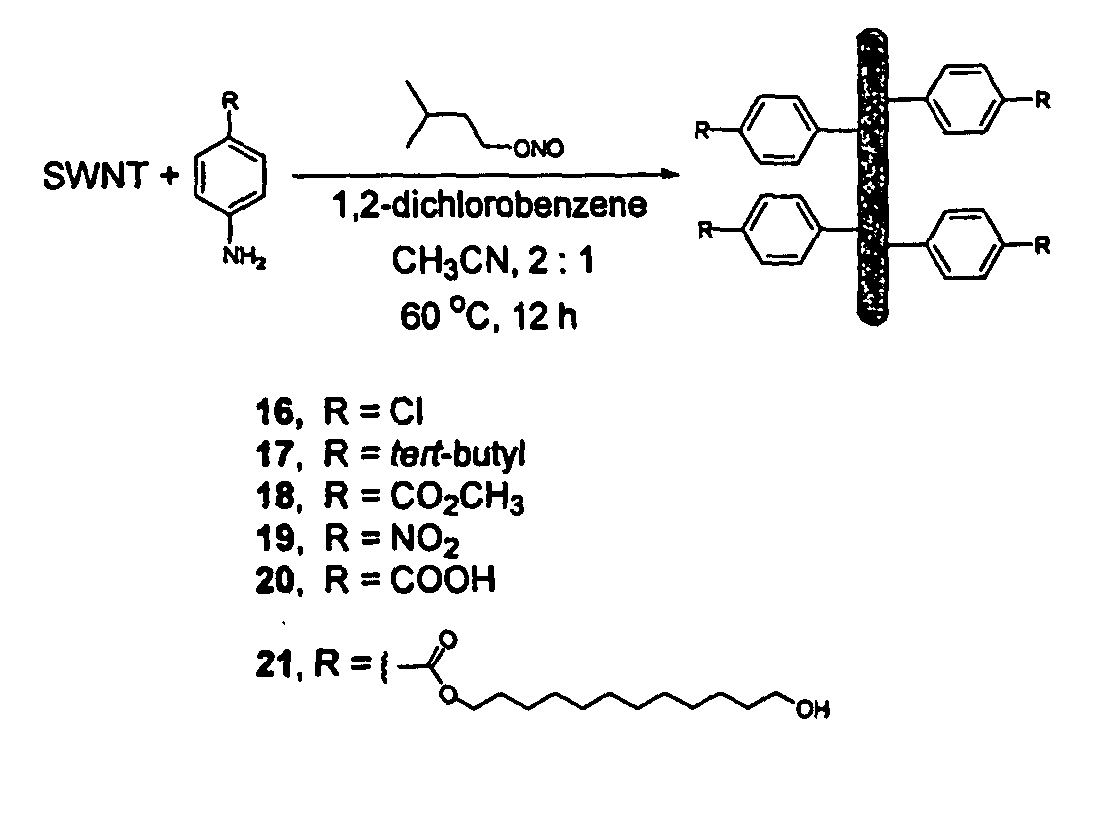

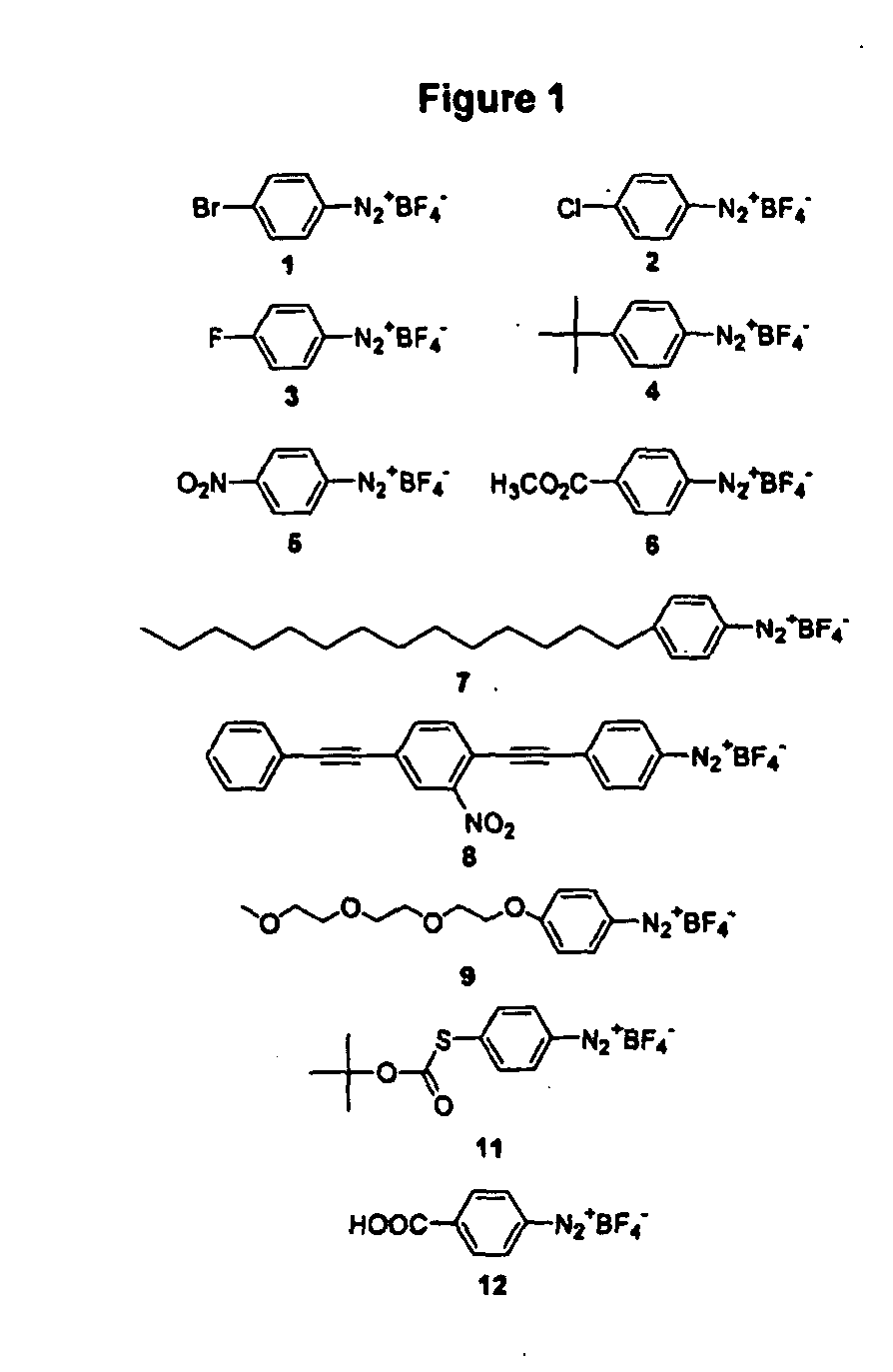

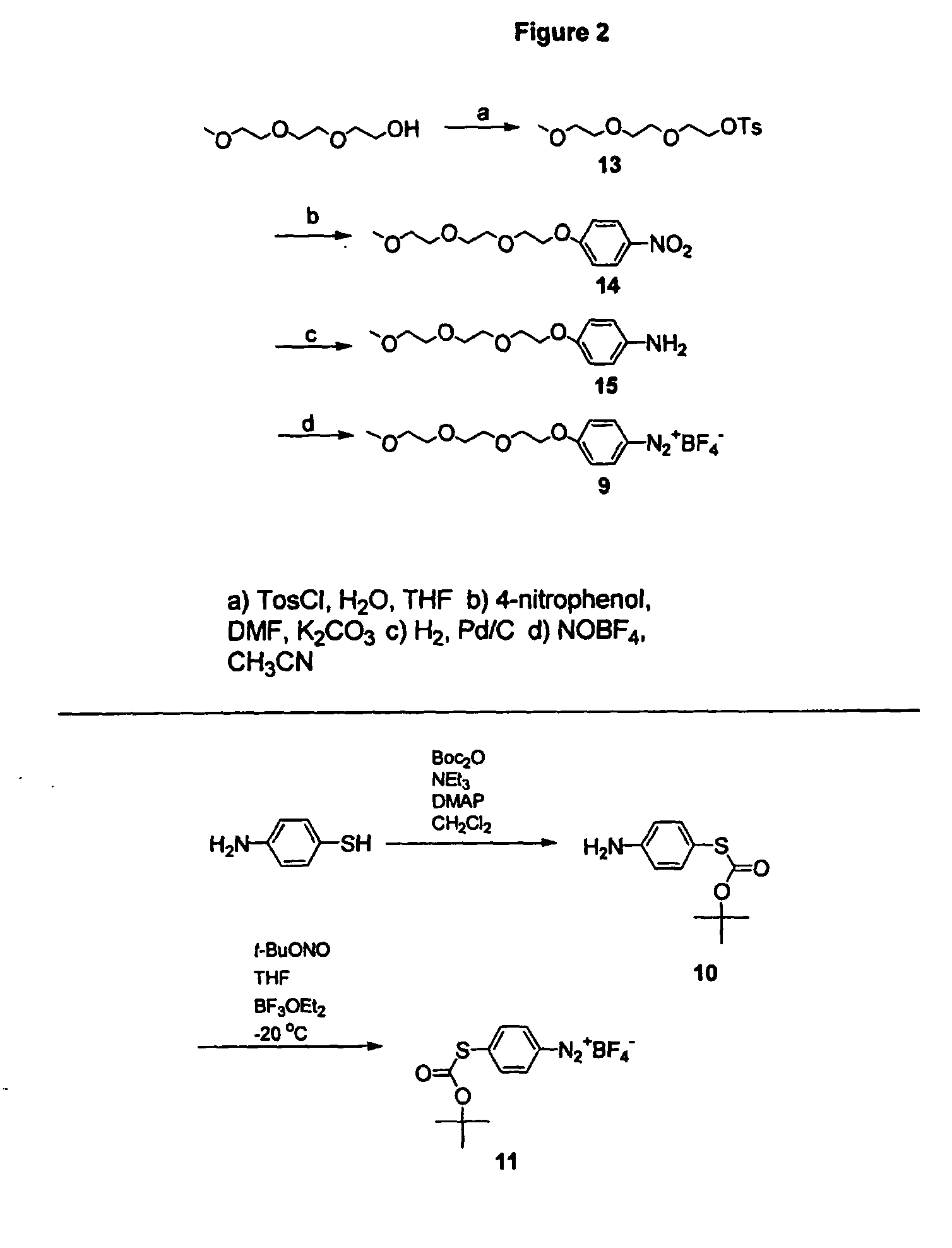

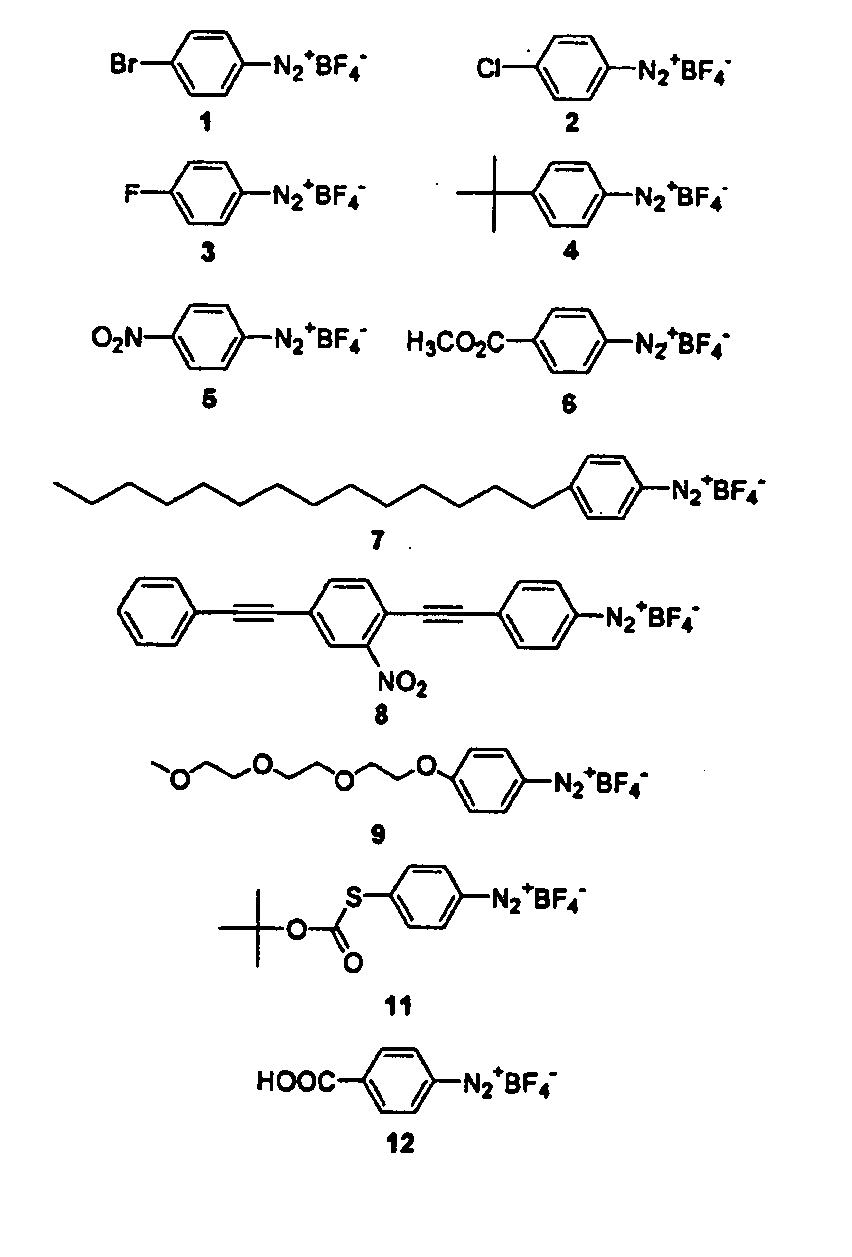

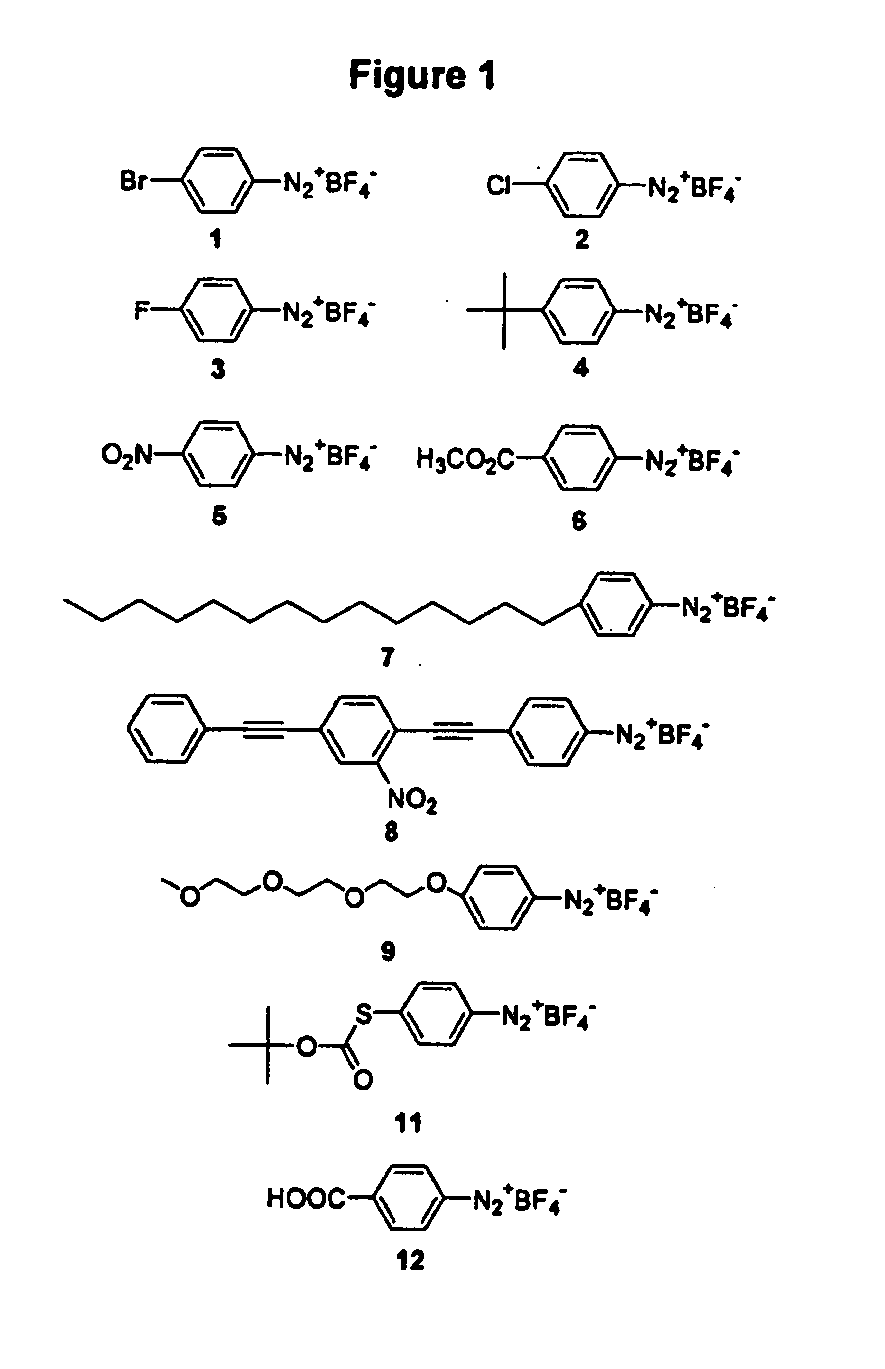

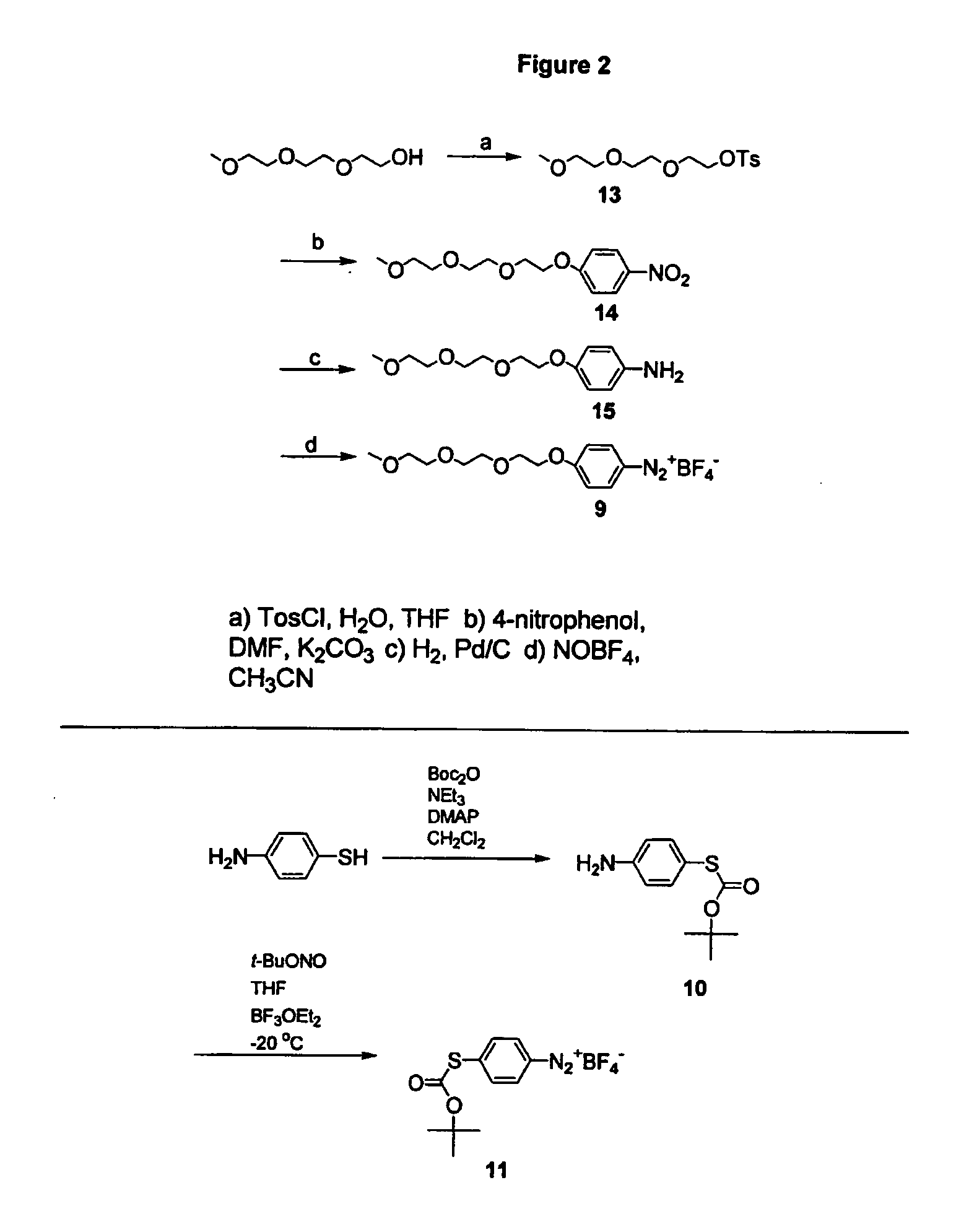

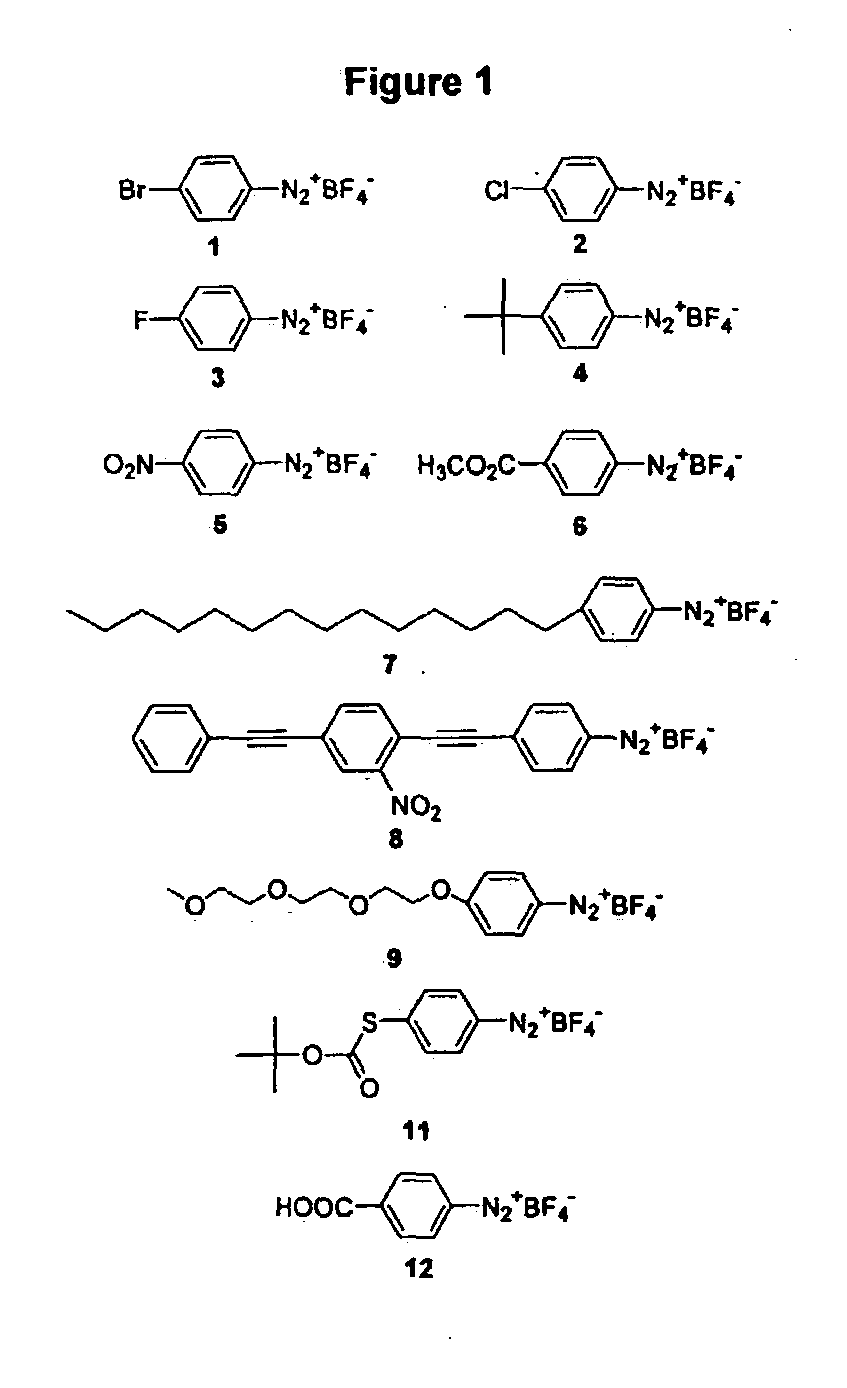

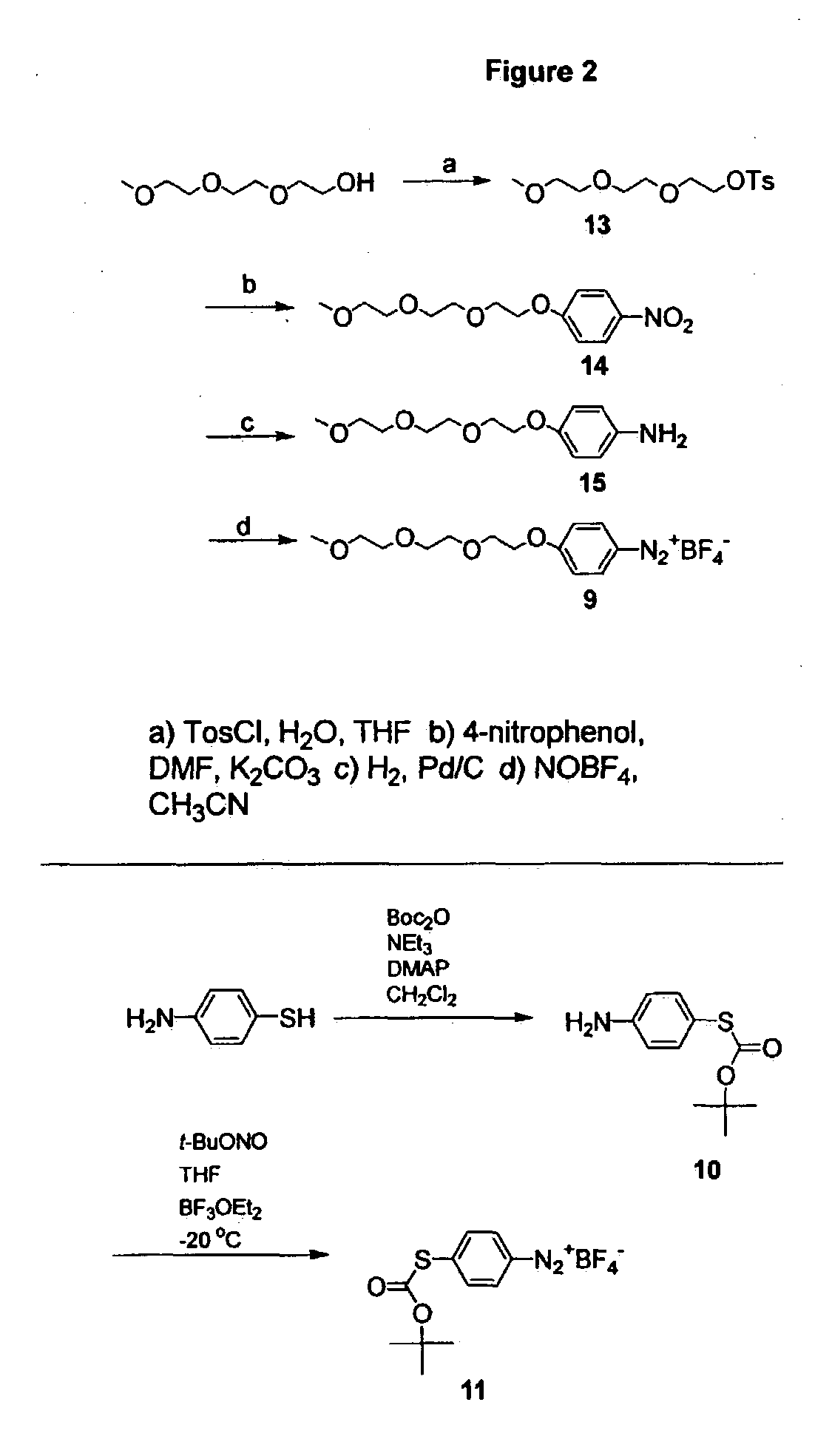

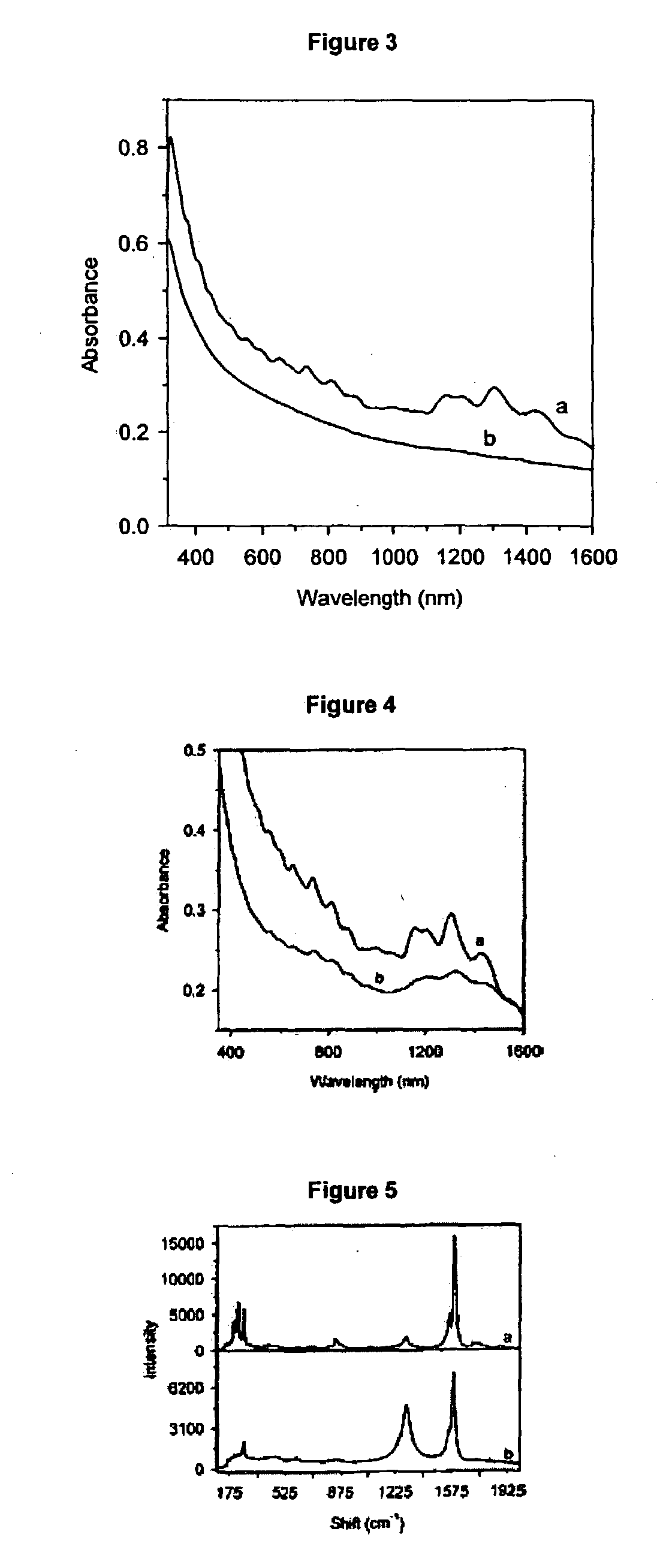

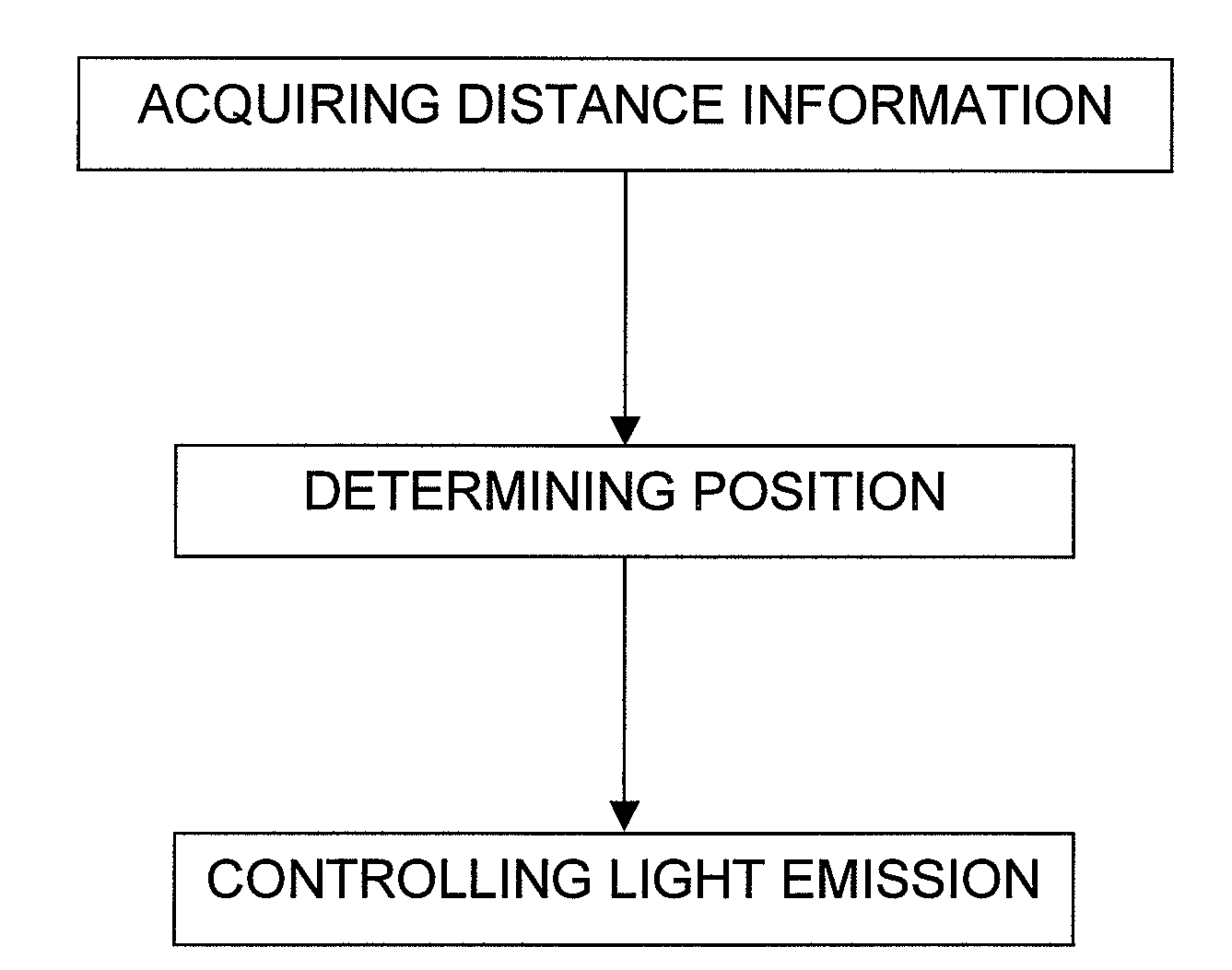

Carbon nanotubes derivatized with diazonium species

InactiveUS20050207963A1Advantage of scalabilityMaterial nanotechnologyPigmenting treatmentElectrochemistryOrganic compound

Owner:RICE UNIV

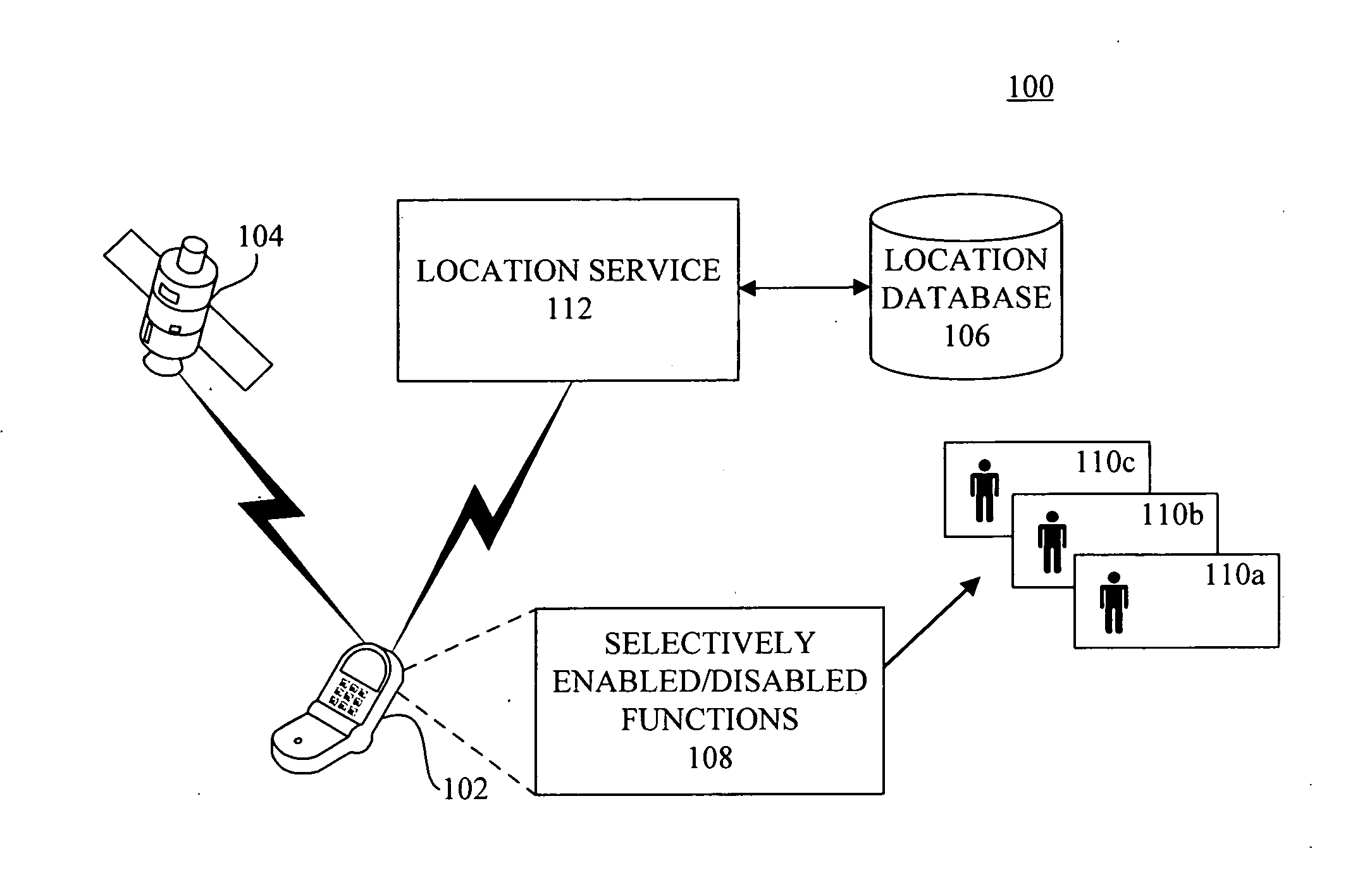

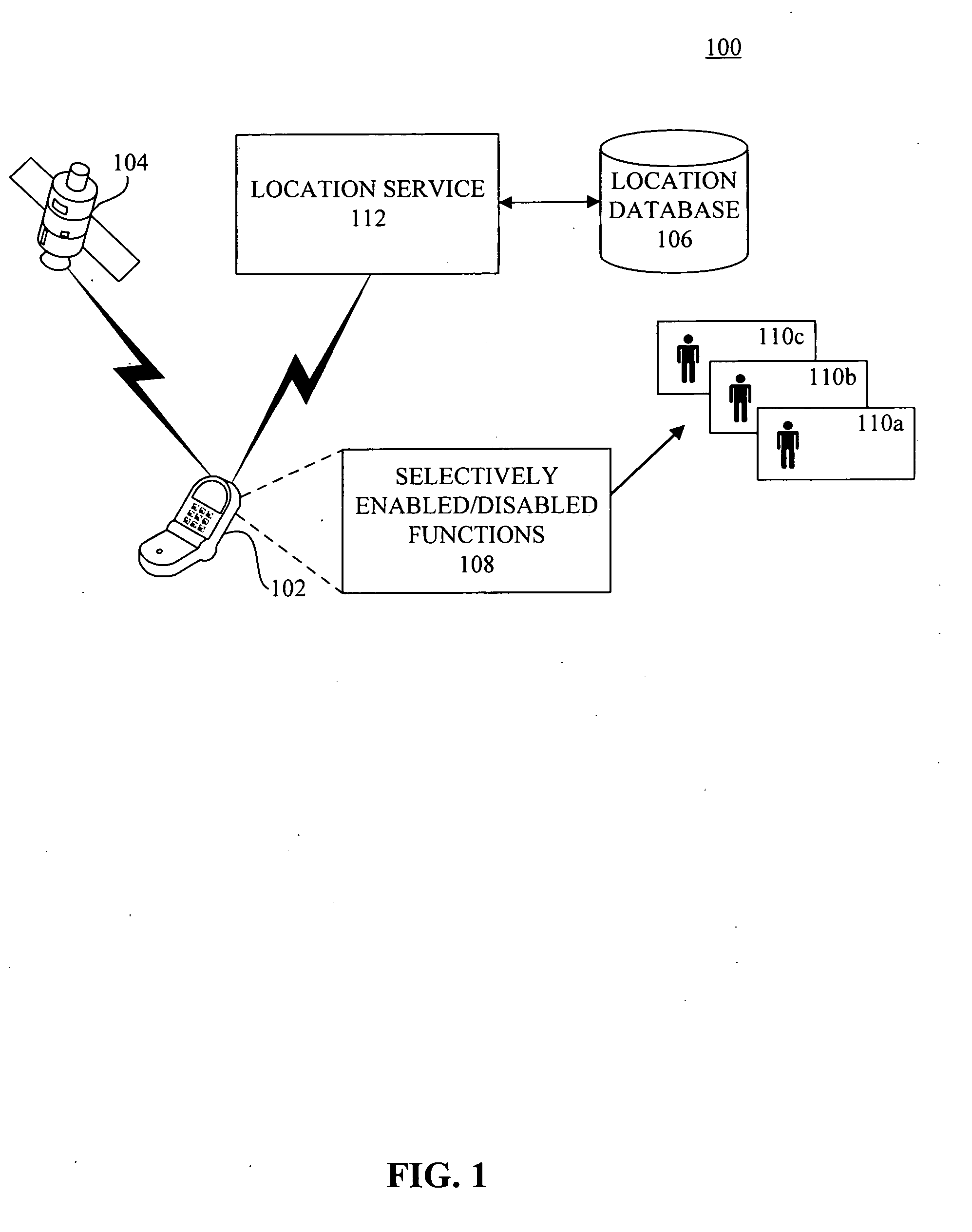

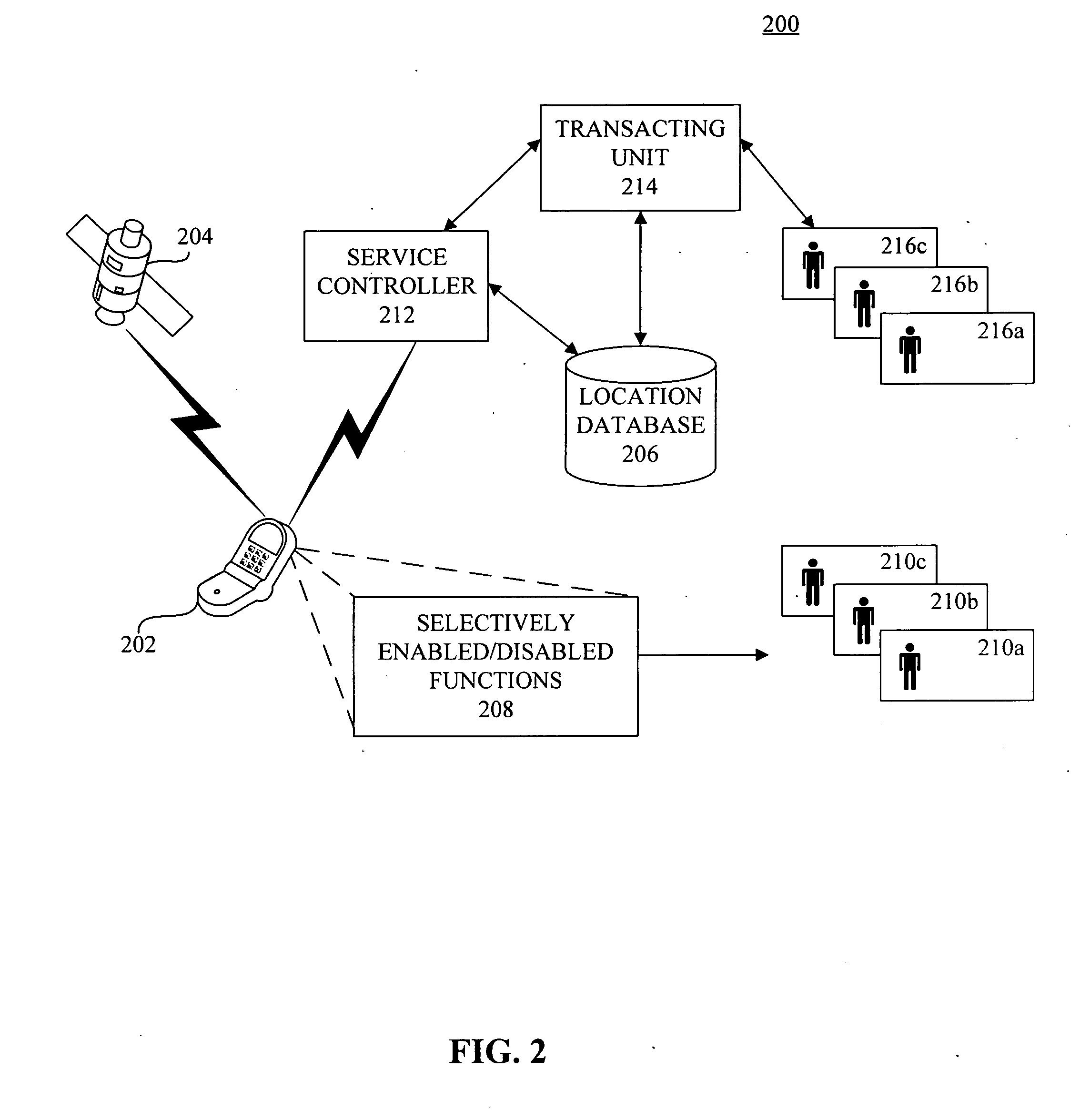

Selective enablement and disablement of a mobile communications device based upon location

ActiveUS20070129083A1Accounting/billing servicesAssess restrictionTelecommunicationsLocation determination

A system for controlling the functionality of a mobile communications device based upon geographic location is provided. The system includes a location determining unit to determine a geographic location of the mobile communications device. The system further includes a location database in communication with the location determining unit. The location database contain one or more data elements designating one or more geographic locations as communications-limited zones within which the mobile communications device is precluded from performing one or more predetermined functions.

Owner:IBM CORP

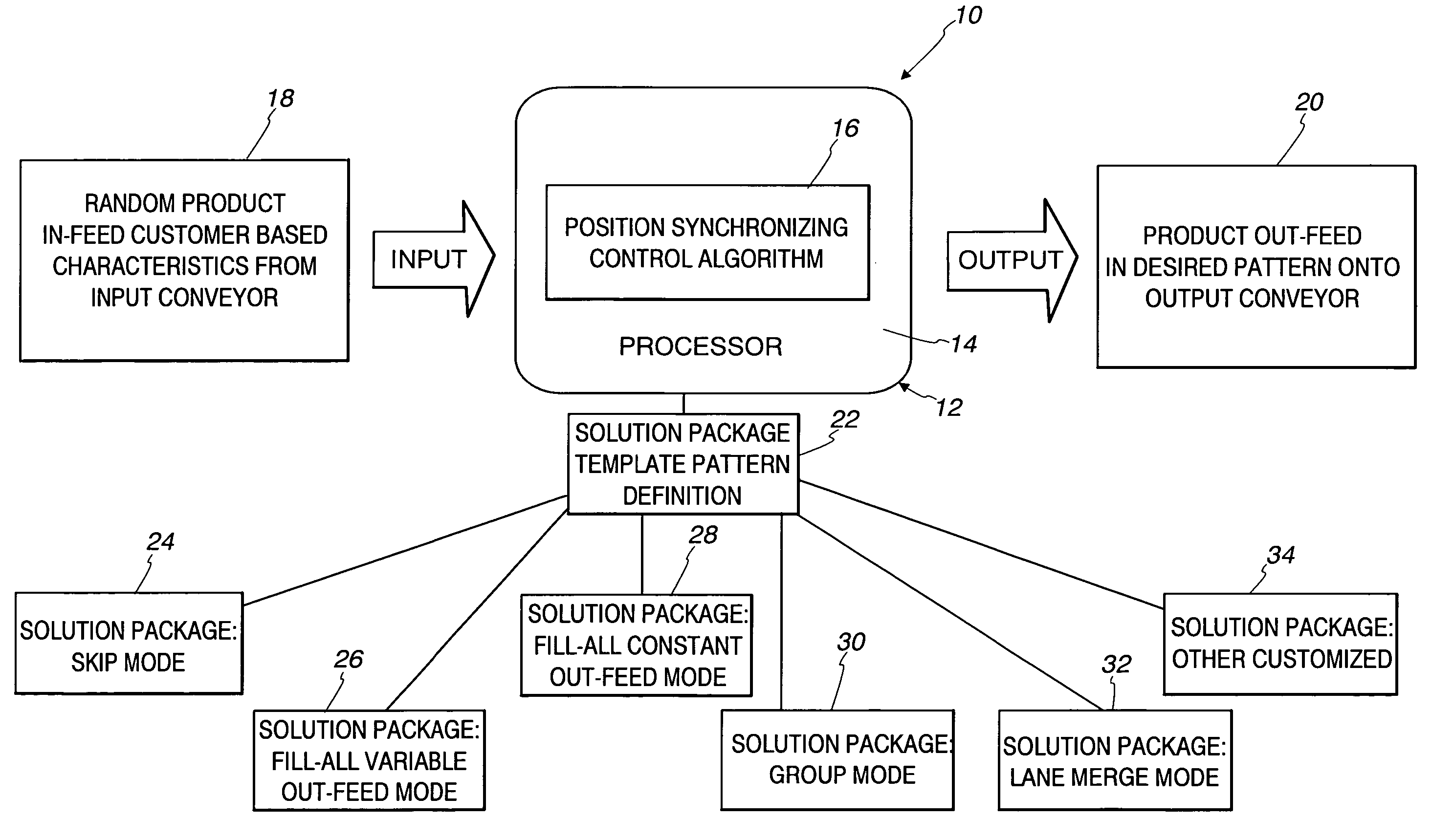

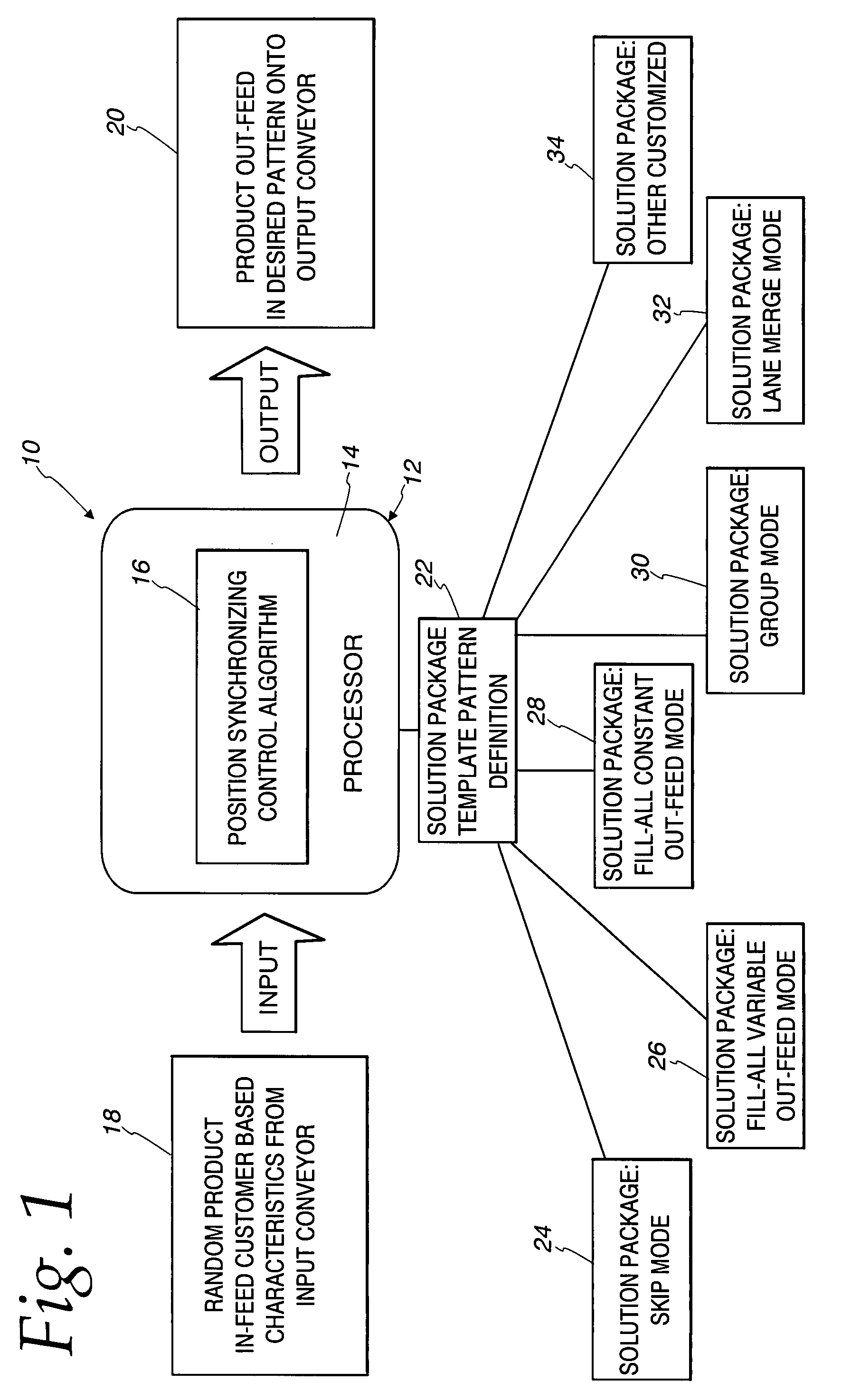

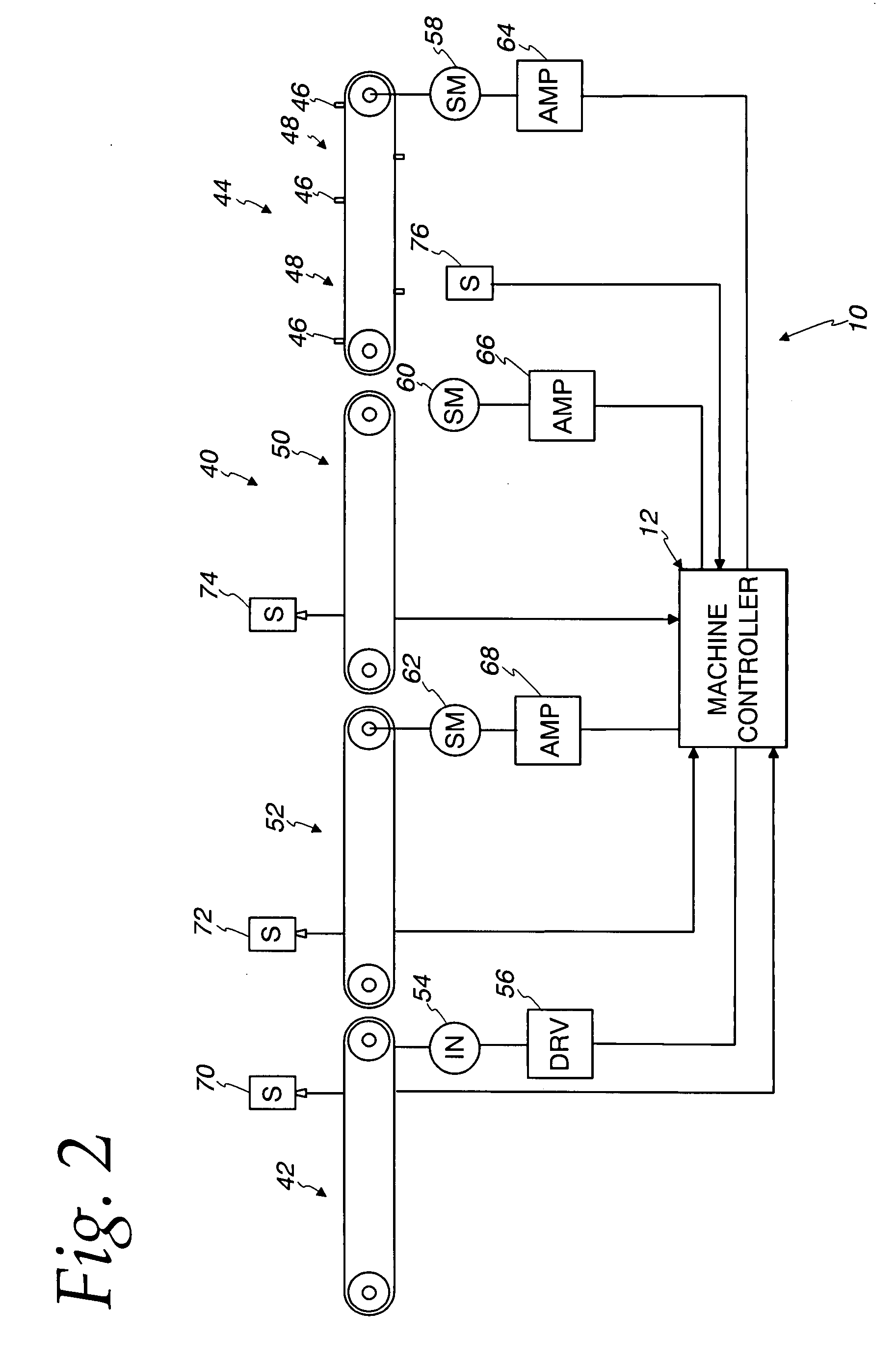

Automated conveying system

InactiveUS20080082206A1Prevent slippingAvoid lossDigital data processing detailsControl devices for conveyorsControl systemProduct pattern

An automated control system is described for a conveying system including an input conveyor supplying a product, a segmented output conveyor delivering a product in a pattern, and one or more synchronizing conveyors disposed between the input conveyor and the output conveyor. The control system comprises a plurality of product position sensors for sensing position of product on each synchronizing conveyor. A conveyor sensor senses segment position of the output conveyor. A plurality of drives, one for each respective conveyor, control the respective conveyors. A database stores a plurality of template pattern algorithms each defining a control algorithm for a distinct product pattern to be delivered from the segmented output conveyor. A controller is operatively connected to the product position sensors, the conveyor sensor and the drives for controlling the conveyors responsive to sensed product position and segment position. The controller includes a programmable processor operable to download a select one of the template pattern algorithms. The controller selectively advances or retards product position relative to the segment position of the output conveyor to release the products onto the output conveyor according to the distinct product pattern defined by the downloaded template pattern algorithm.

Owner:YASKAWA ELECTRIC AMERICA

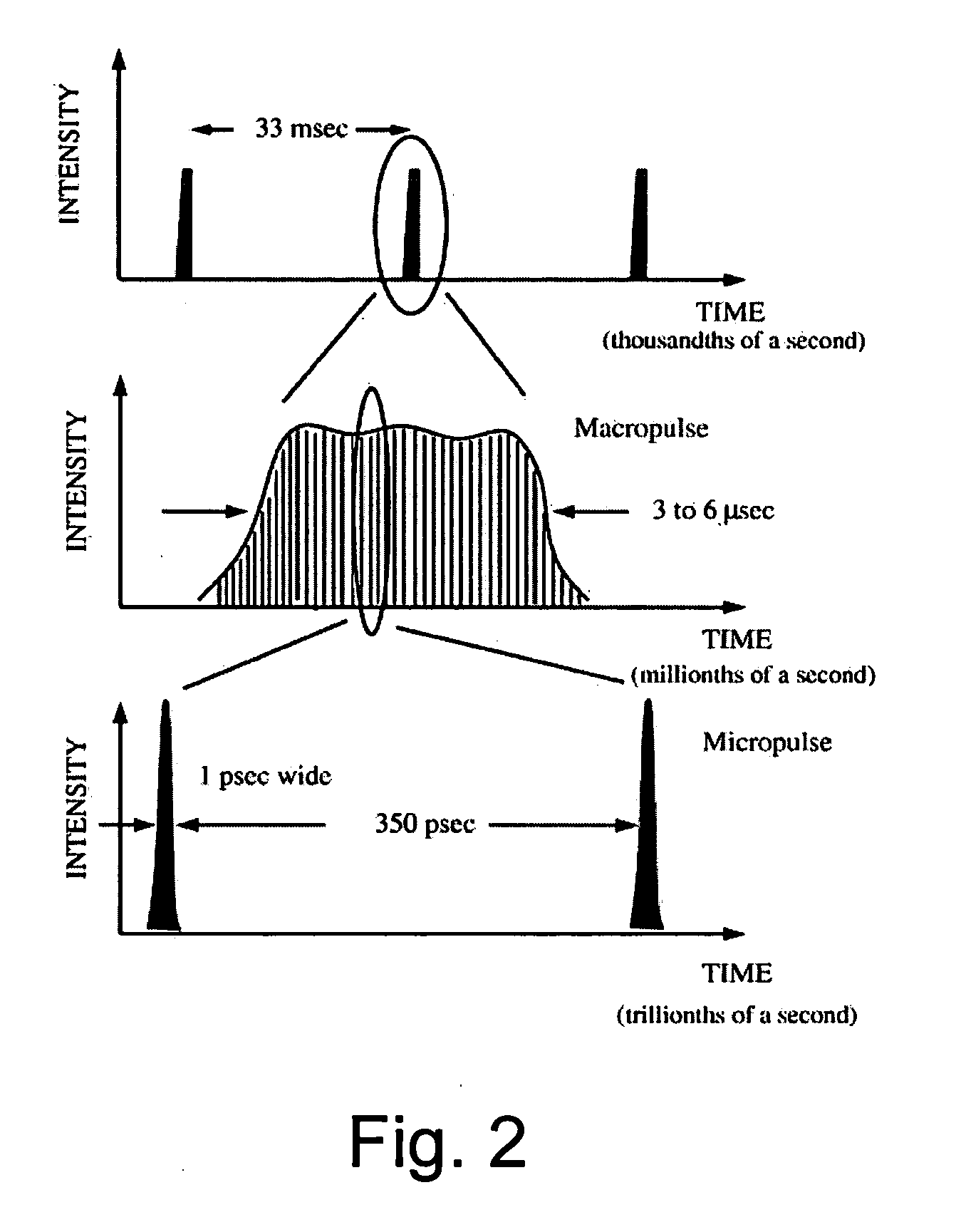

Methods and apparatus for transferring a material onto a substrate using a resonant infrared pulsed laser

InactiveUS20090169868A1Radiation applicationsSynthetic resin layered productsLength waveMaterial transfer

A method for transferring a material onto a substrate. In one embodiment, the method includes the steps of directing a coherent light of a wavelength resonant with a vibrational mode of the material at the material to vaporize the material, depositing the vaporized material on the substrate in a form that is essentially same chemically as the material, and selectively heating the deposited material at one or more positions of the substrate to form a film thereon.

Owner:VANDERBILT UNIV

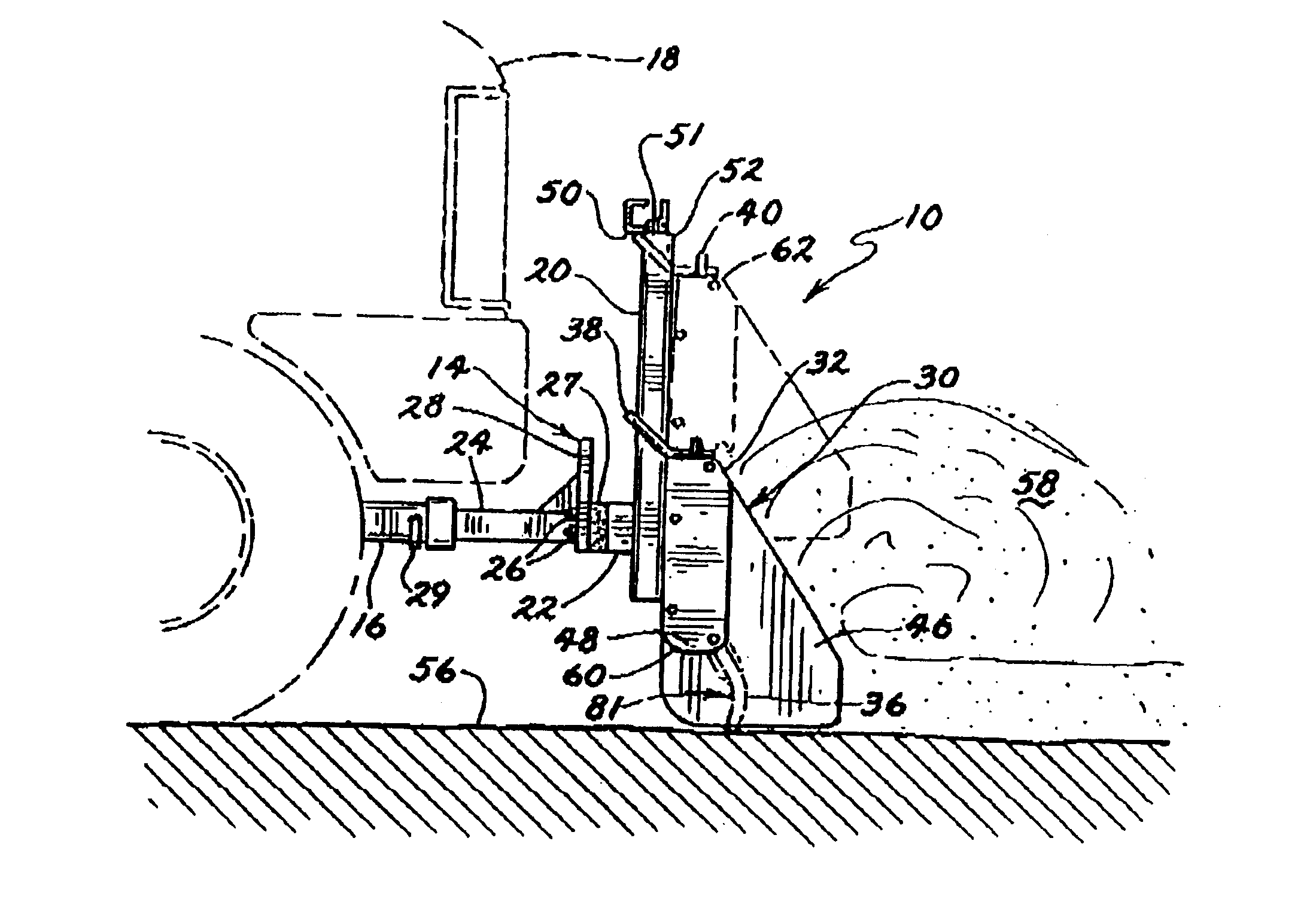

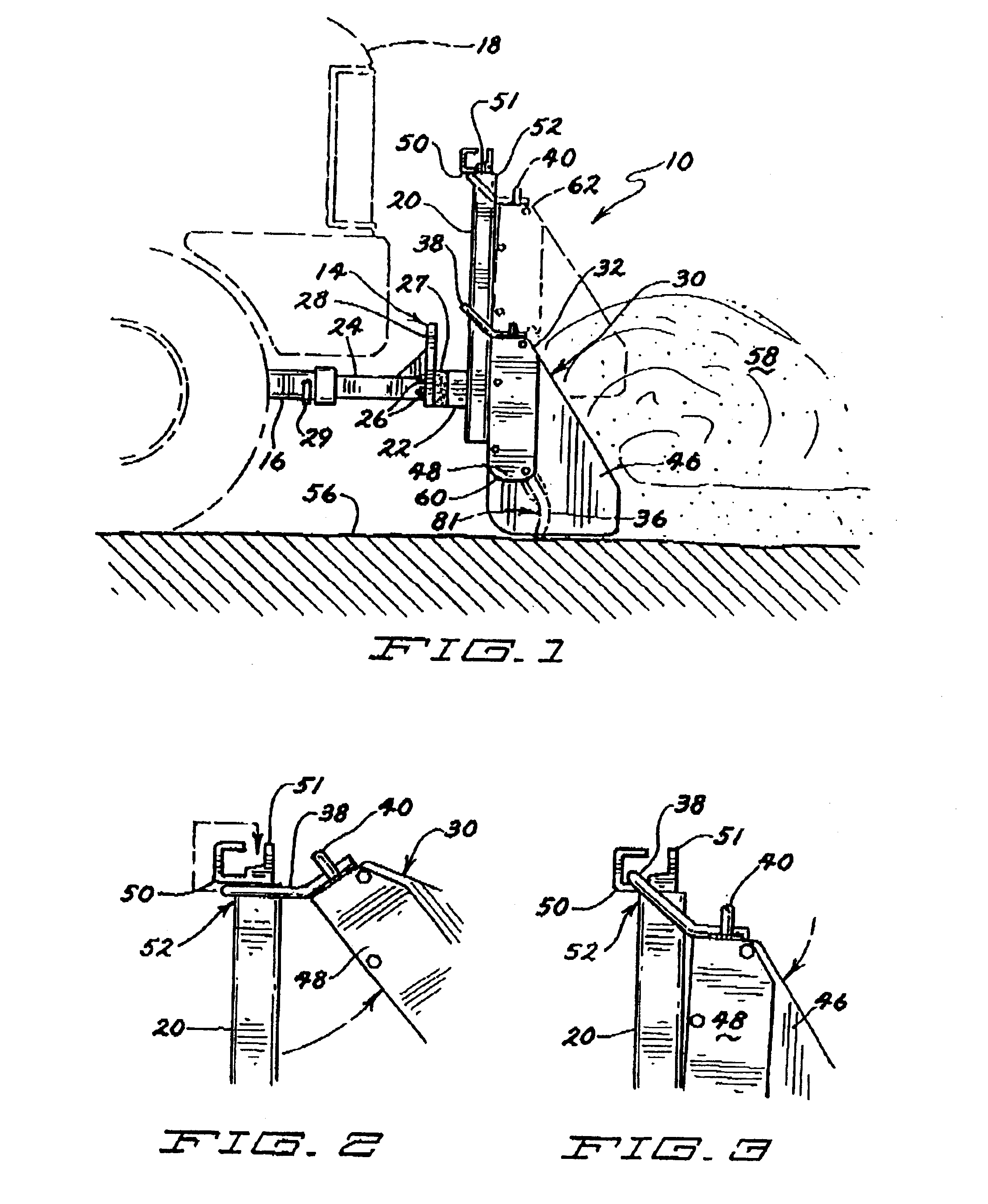

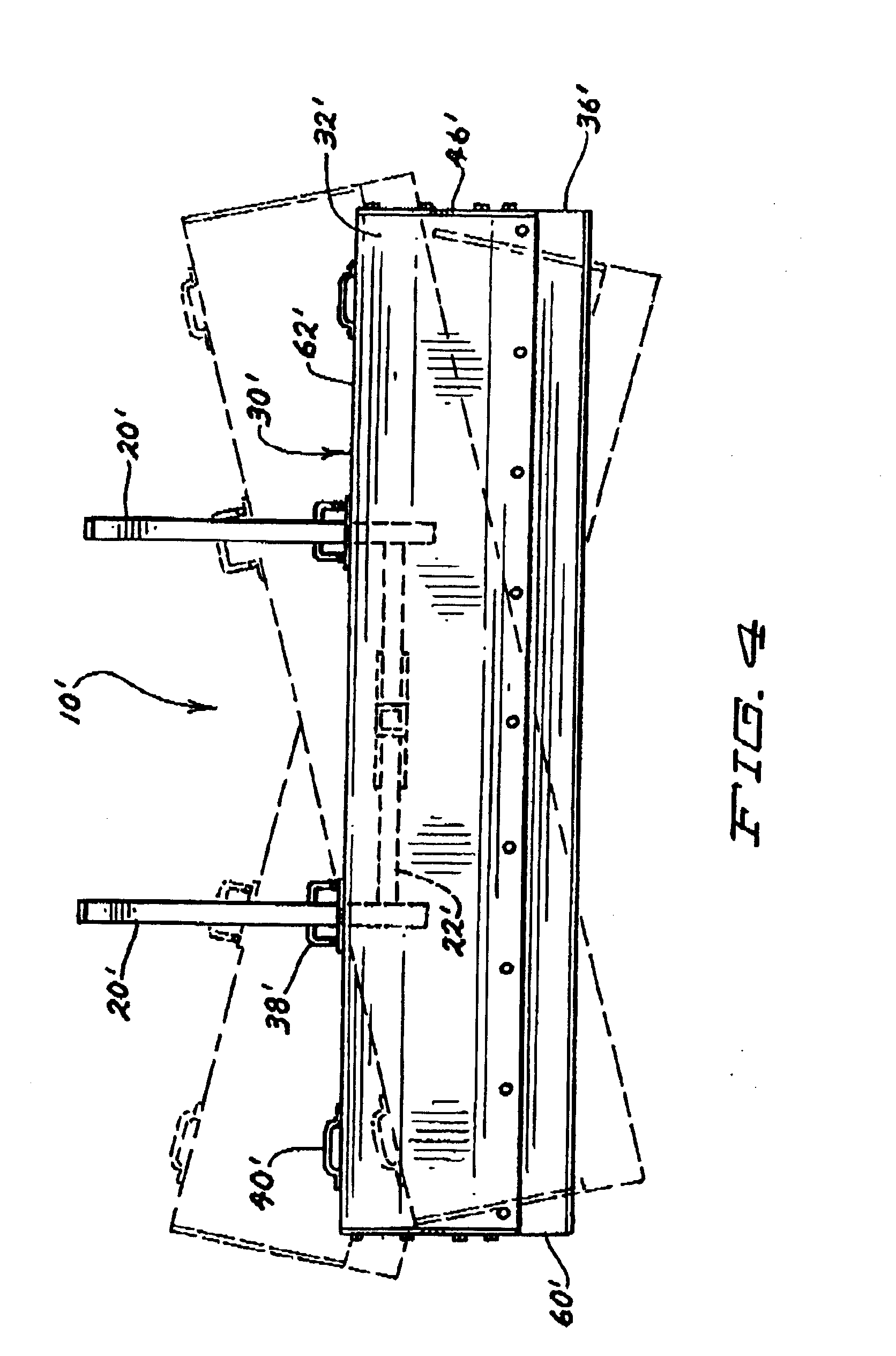

Multifunctional plow blade positioning apparatus and method

InactiveUS20070062073A1Improve practicalityEasy to liftMechanical machines/dredgersSnow cleaningPickup truckAgricultural engineering

A self-adjusting snow plow for use with pickup trucks, SUVs, all-terrain vehicles or other land vehicles. The snow plow includes a mounting apparatus for attachment to a vehicle and a plow blade, preferably including a mold board and a retention apparatus assembly. The retention apparatus assembly disengageably secures the plow blade to the mounting apparatus when the plow blade is in a snow displacement position. The snow plow further includes an elongated strap selectively connectable between the plow blade and the mounting apparatus in at least one position, wherein the position is a constrained orientation wherein the elongated strap resists upward movement of the plow blade when the plow blade is disengageably secured to the mounting apparatus or an elevated orientation, wherein the elongated strap suspends the plow blade a desired distance from the ground to prevent the plow blade from contacting the ground and / or snow on the ground.

Owner:AGRI COVER

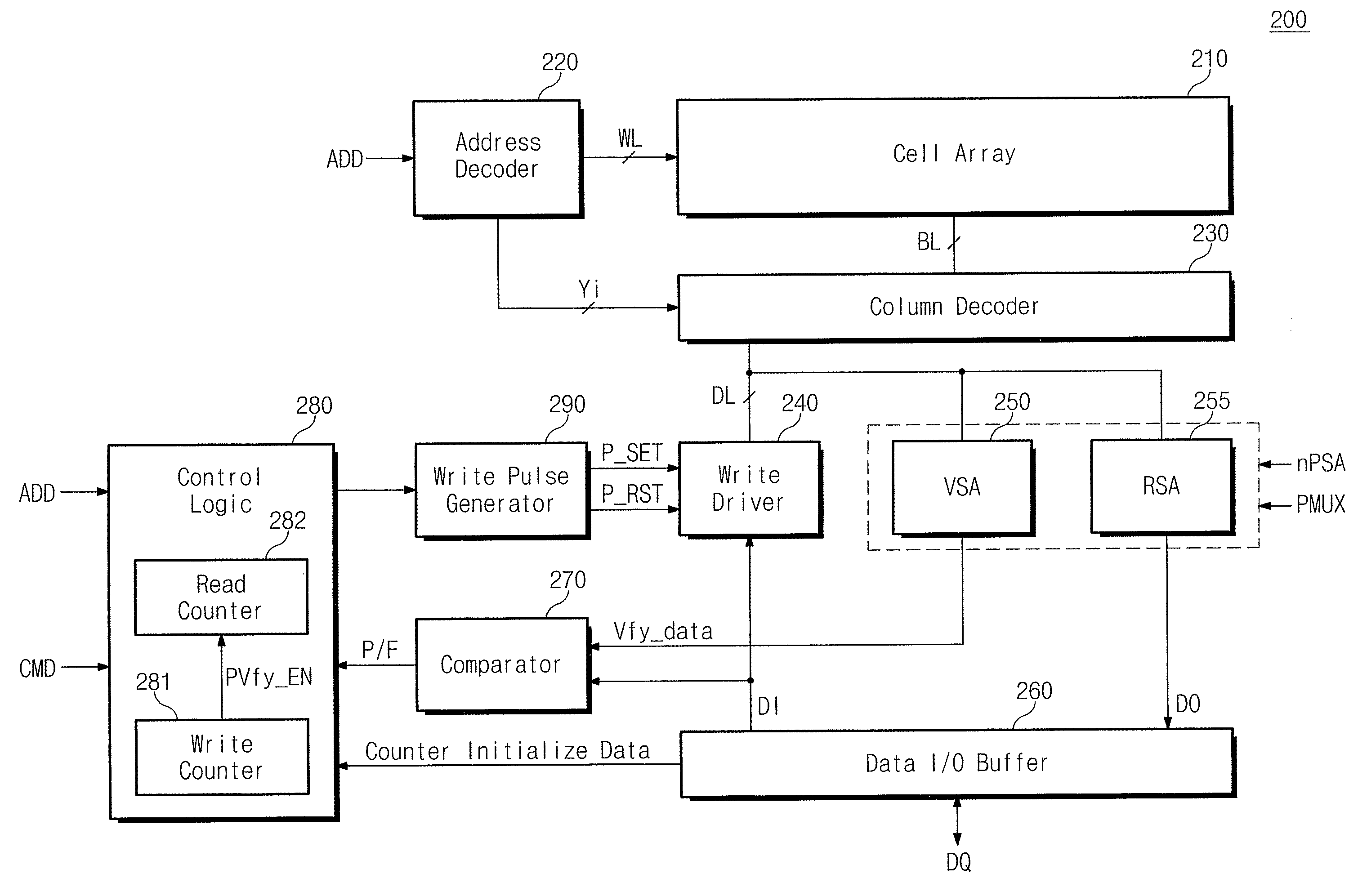

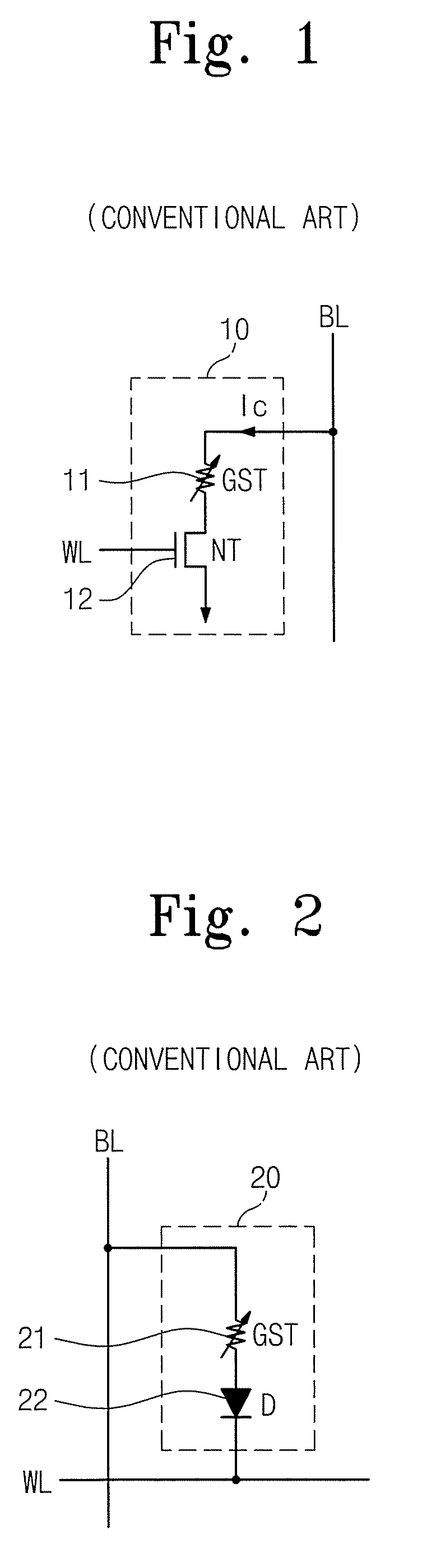

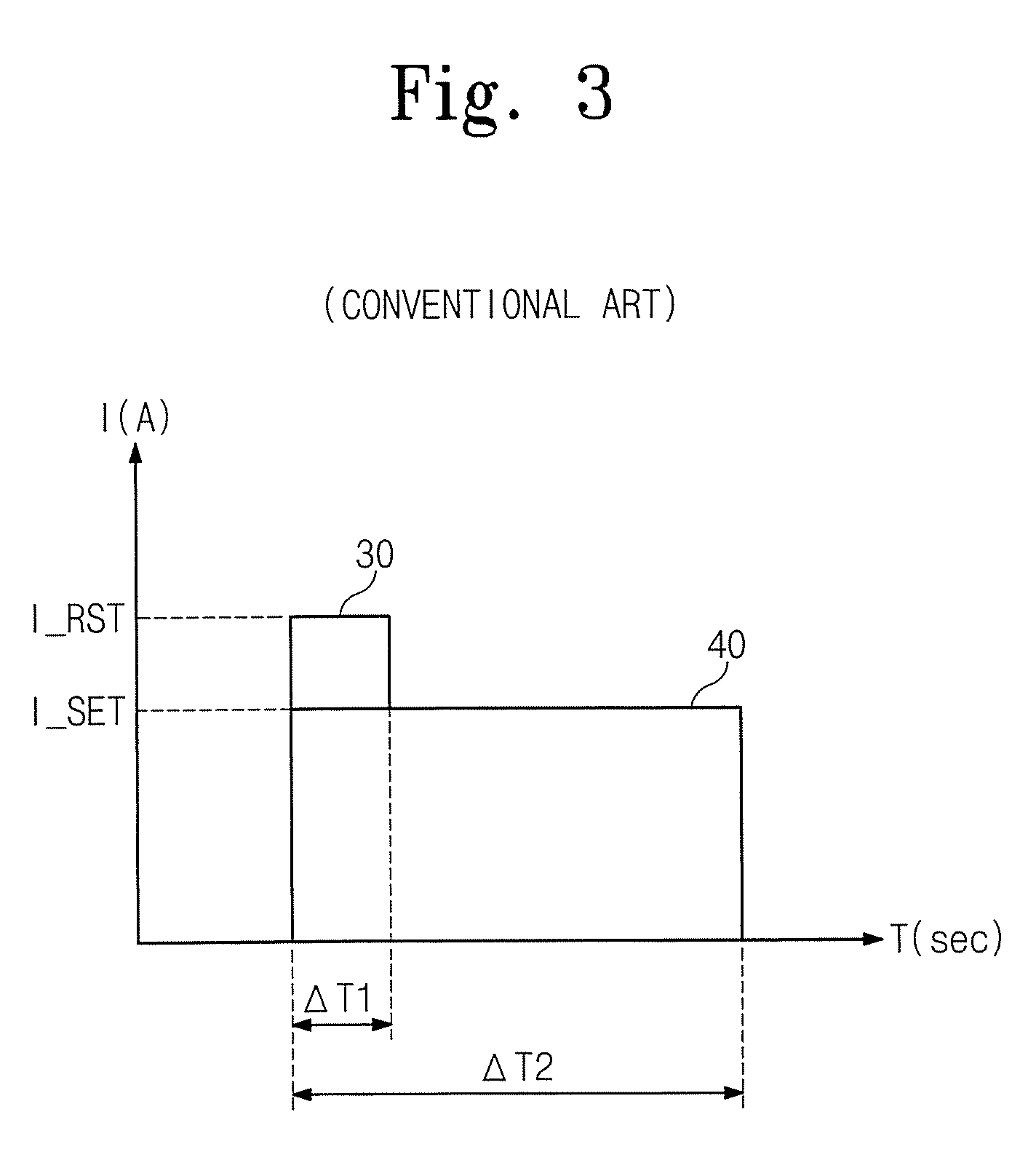

Memory devices with selective pre-write verification and methods of operation thereof

A number of read cycles applied to a selected memory location of a memory device, such as a variable-resistance memory device, is monitored. Write data to be written to the selected memory location is received. Selective pre-write verifying and writing of the received write data to the selected memory location occurs based on the monitored number of read cycles. Selectively pre-write verifying and writing of the received write data may include, for example, writing received write data to the selected memory cell region without pre-write verification responsive to the monitored number of read cycles being greater than a predetermined number of read cycles

Owner:SAMSUNG ELECTRONICS CO LTD

Regulating device

Owner:TECHNOGYM SPA

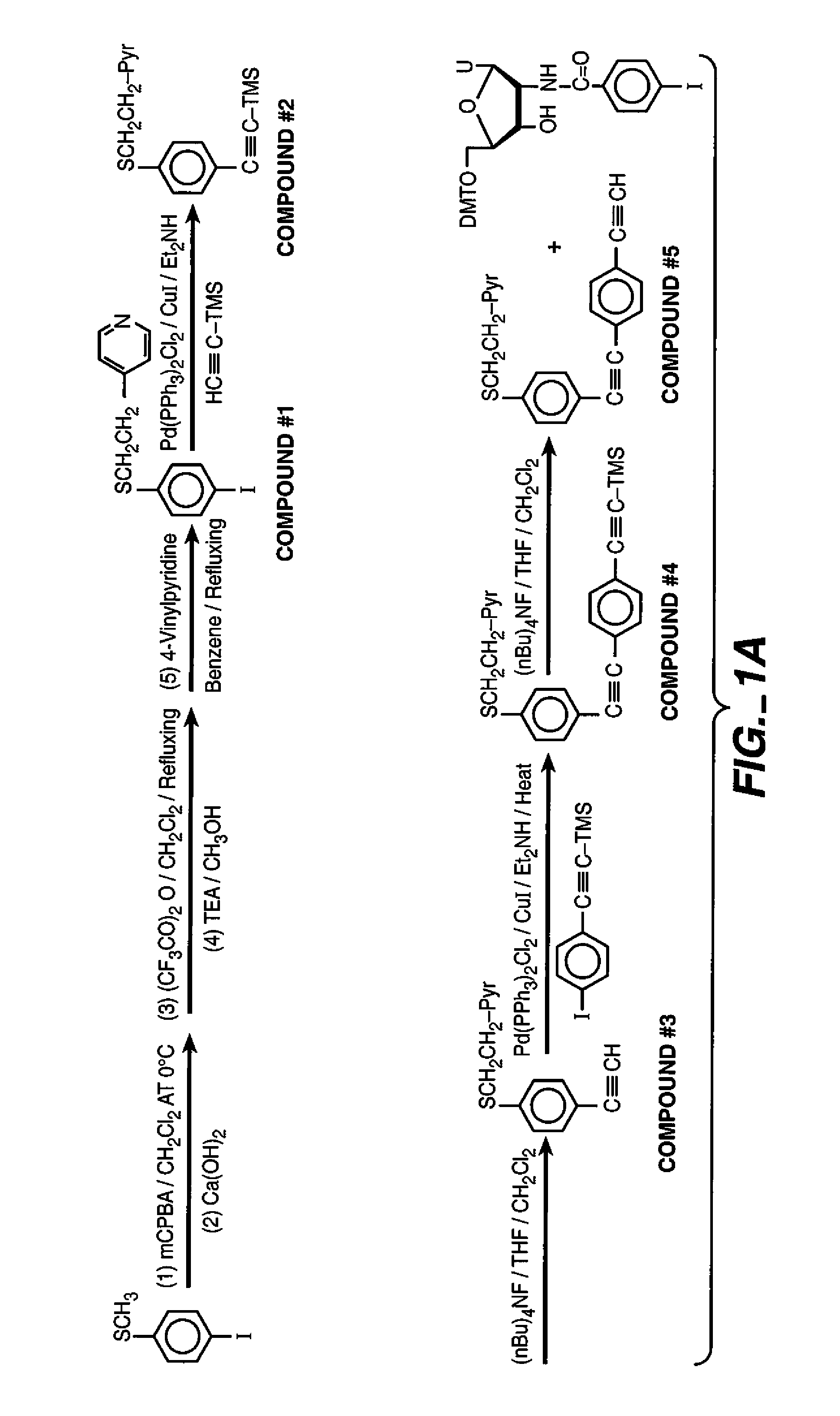

Process for attaching molecular wires and devices to carbon nanotubes and compositions thereof

InactiveUS20050074613A1Advantage of scalabilityPigmenting treatmentMaterial nanotechnologyElectrochemistryOrganic compound

The invention incorporates new processes for the chemical modification of carbon nanotubes. Such processes involve the derivatization of multi- and single-wall carbon nanotubes, including small diameter (ca. 0.7 nm) single-wall carbon nanotubes, with diazonium species. The method allows the chemical attachment of a variety of organic compounds to the side and ends of carbon nanotubes. These chemically modified nanotubes have applications in polymer composite materials, molecular electronic applications, and-sensor devices. The methods of derivatization include electrochemical induced reactions, thermally induced reactions (via in-situ generation of diazonium compounds or pre-formed diazonium compounds), and photochemically induced reactions. The derivatization causes significant changes in the spectroscopic properties of the nanotubes. The estimated degree of functionality is ca. 1 out of every 20 to 30 carbons in a nanotube bearing a functionality moiety. Such electrochemical reduction processes can be adapted to apply site-selective chemical functionalization of nanotubes. Moreover, when modified with suitable chemical groups, the derivatized nanotubes are chemically compatible with a polymer matrix, allowing transfer of the properties of the nanotubes (such as, mechanical strength or electrical conductivity) to the properties of the composite material as a whole. Furthermore, when modified with suitable chemical groups, the groups can be polymerized to form a polymer that includes carbon nanotubes.

Owner:RICE UNIV

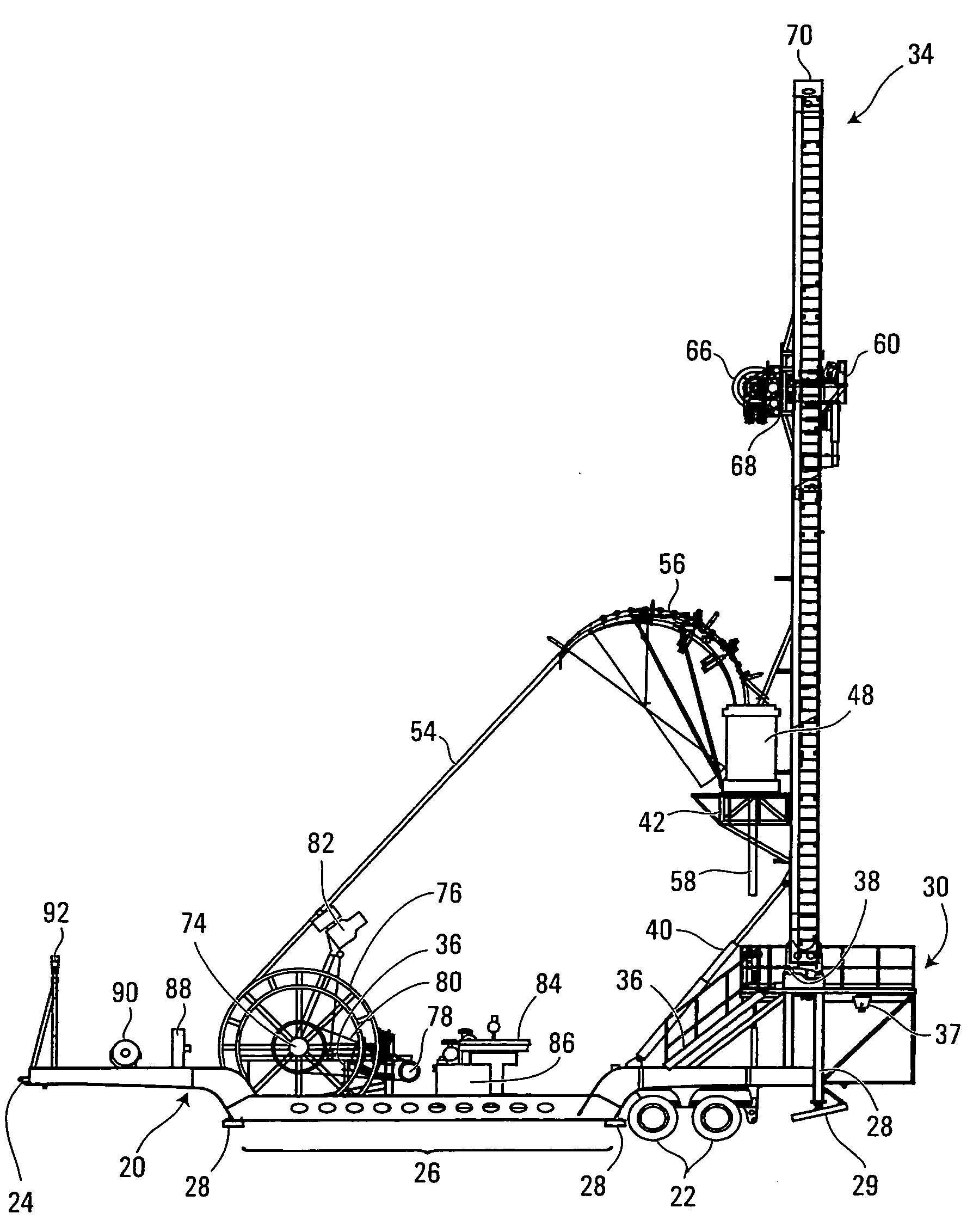

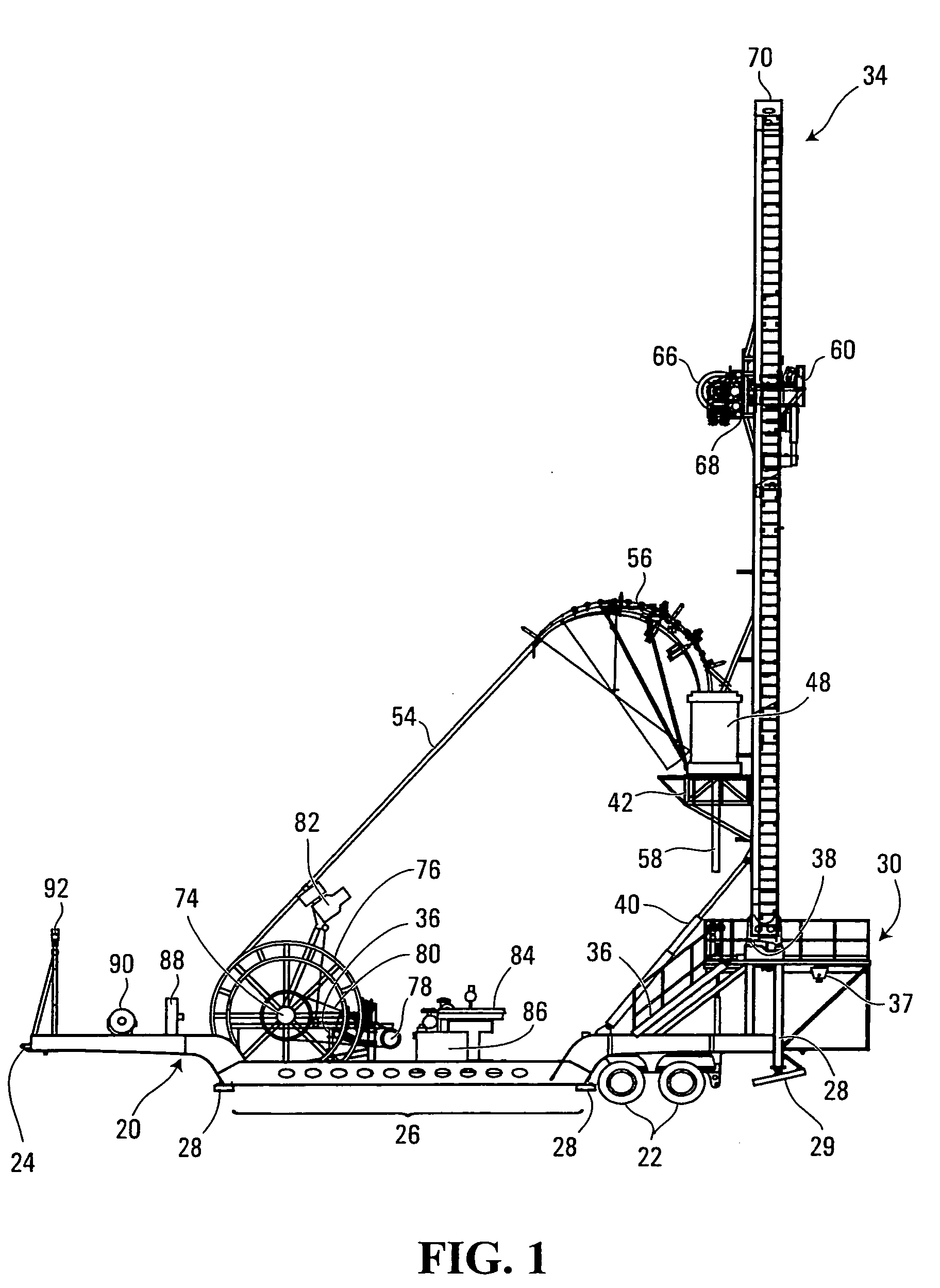

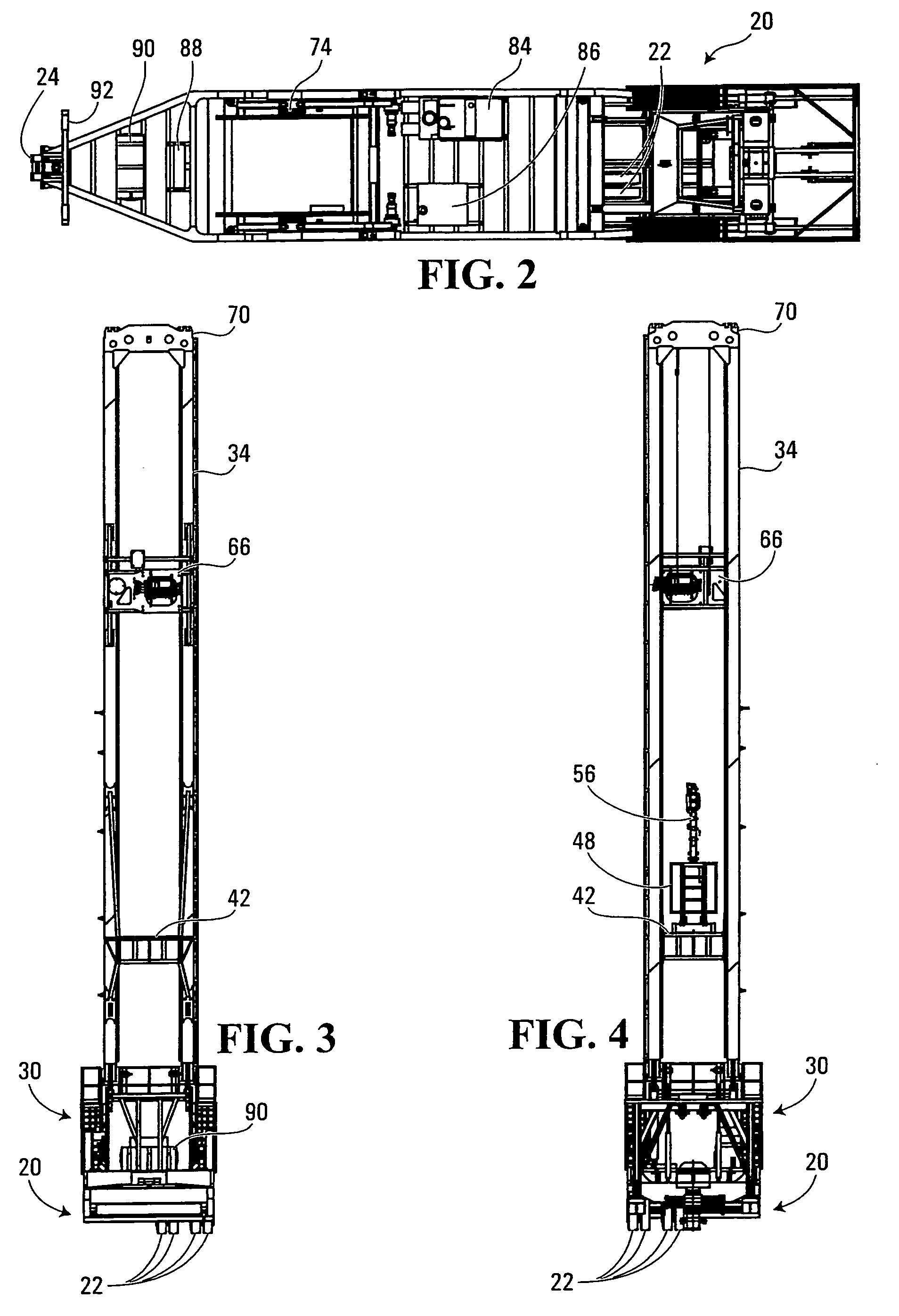

Drilling rig apparatus and downhole tool assembly system and method

InactiveUS20060027373A1Easy and time-efficient assemblyDrilling rodsDerricks/mastsTop driveCoiled tubing

Owner:SAVANNA ENERGY SERVICES

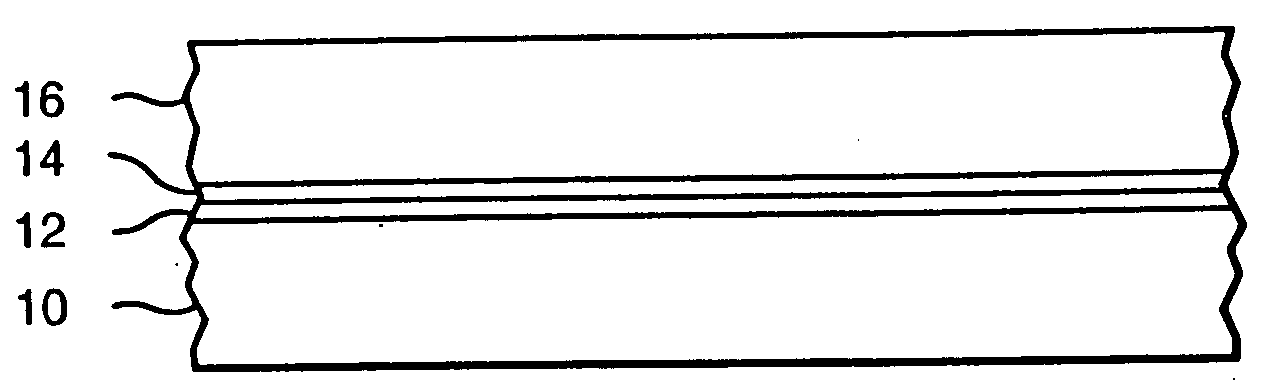

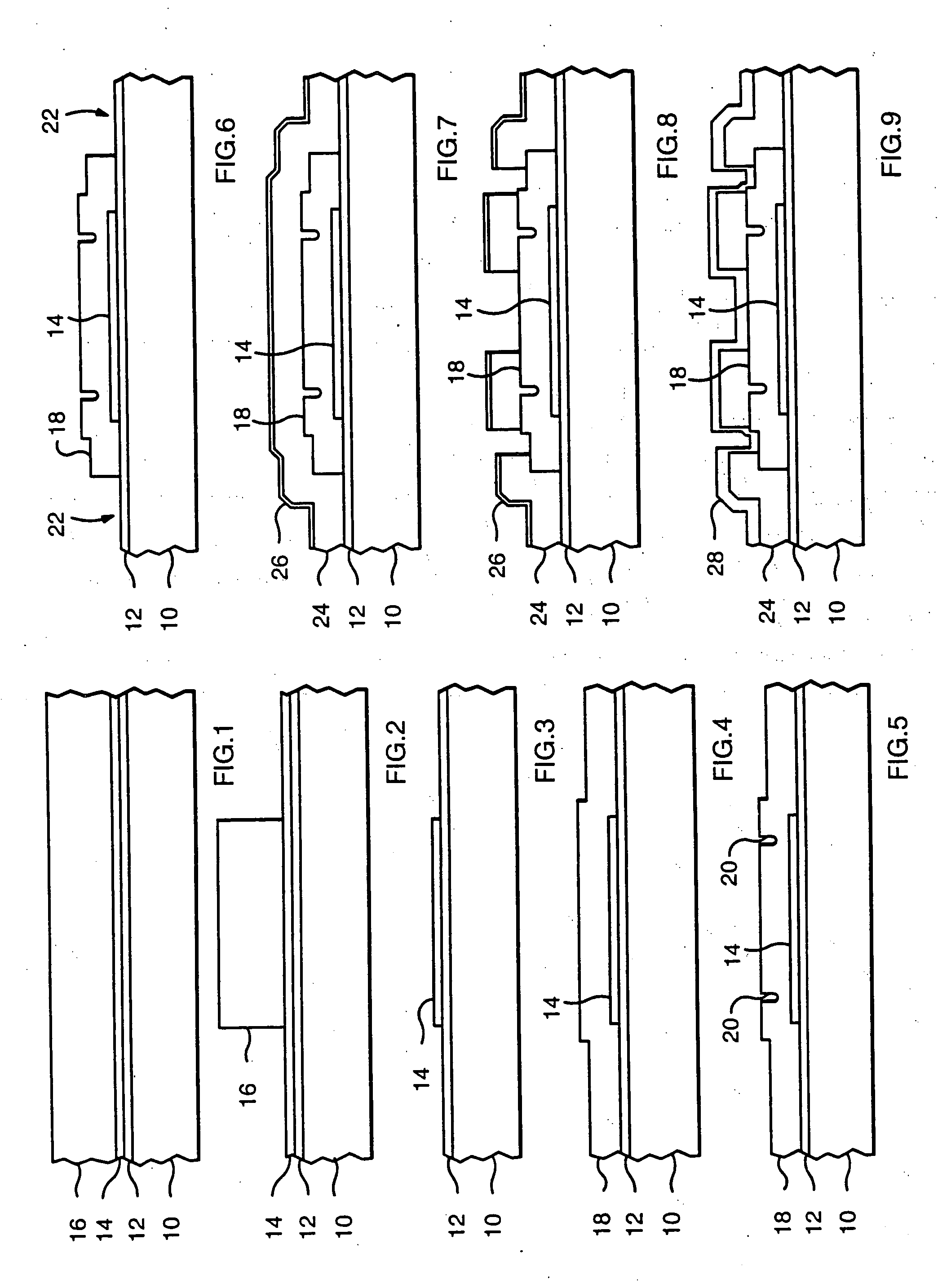

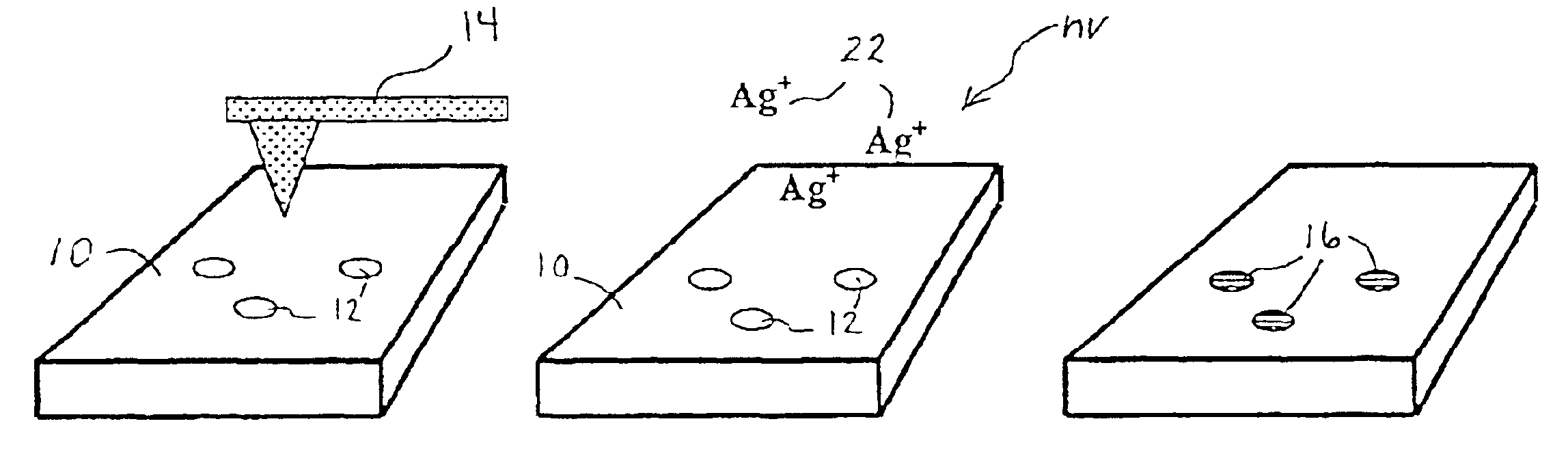

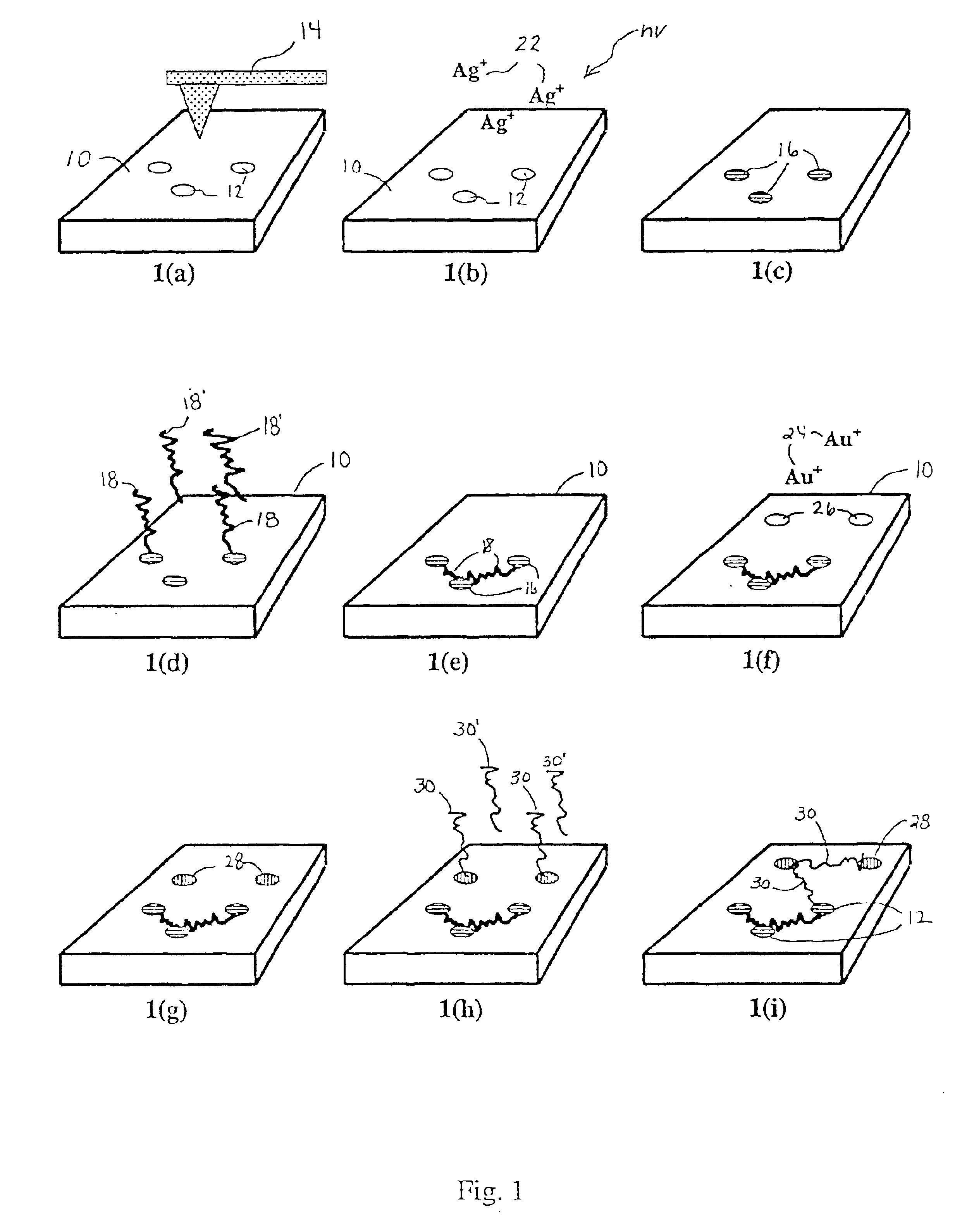

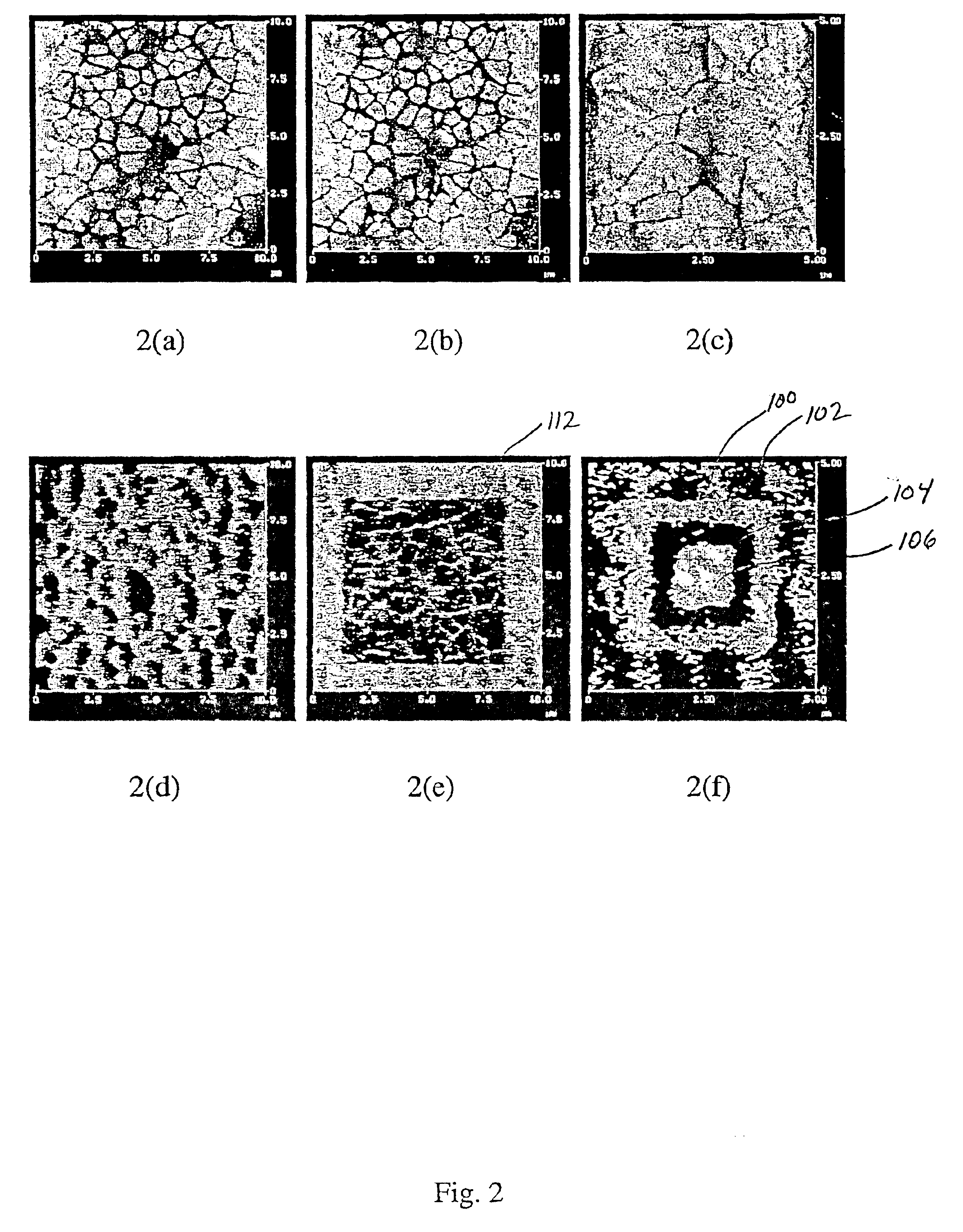

Directed assembly of nanometer-scale molecular devices

InactiveUS6982174B2Material nanotechnologyNanostructure manufactureComputational chemistrySurface charges

A ferroelectric substrate (10) is patterned using local electric fields from an apparatus (14) to produce nanometer sized domains with controlled surface charge (12), that allow site selective metalization (22) and subsequent reaction with functional molecules (18), resulting in nanometer-scale molecular devices.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Process for making polymers comprising derivatized carbon nanotubes and compositions thereof

InactiveUS20050074390A1Advantage of scalabilityMaterial nanotechnologyPigmenting treatmentElectrochemistryOrganic compound

The invention incorporates new processes for the chemical modification of carbon nanotubes. Such processes involve the derivatization of multi- and single-wall carbon nanotubes, including small diameter (ca. 0.7 nm) single-wall carbon nanotubes, with diazonium species. The method allows the chemical attachment of a variety of organic compounds to the side and ends of carbon nanotubes. These chemically modified nanotubes have applications in polymer composite materials, molecular electronic applications, and sensor devices. The methods of derivatization include electrochemical induced reactions, thermally induced reactions (via in-situ generation of diazonium compounds or pre-formed diazonium compounds), and photochemically induced reactions. The derivatization causes significant changes in the spectroscopic properties of the nanotubes. The estimated degree of functionality is ca. 1 out of every 20 to 30 carbons in a nanotube bearing a functionality moiety. Such electrochemical reduction processes can be adapted to apply site-selective chemical functionalization of nanotubes. Moreover, when modified with suitable chemical groups, the derivatized nanotubes are chemically compatible with a polymer matrix, allowing transfer of the properties of the nanotubes (such as, mechanical strength or electrical conductivity) to the properties of the composite material as a whole. Furthermore, when modified with suitable chemical groups, the groups can be polymerized to form a polymer that includes carbon nanotubes.

Owner:RICE UNIV

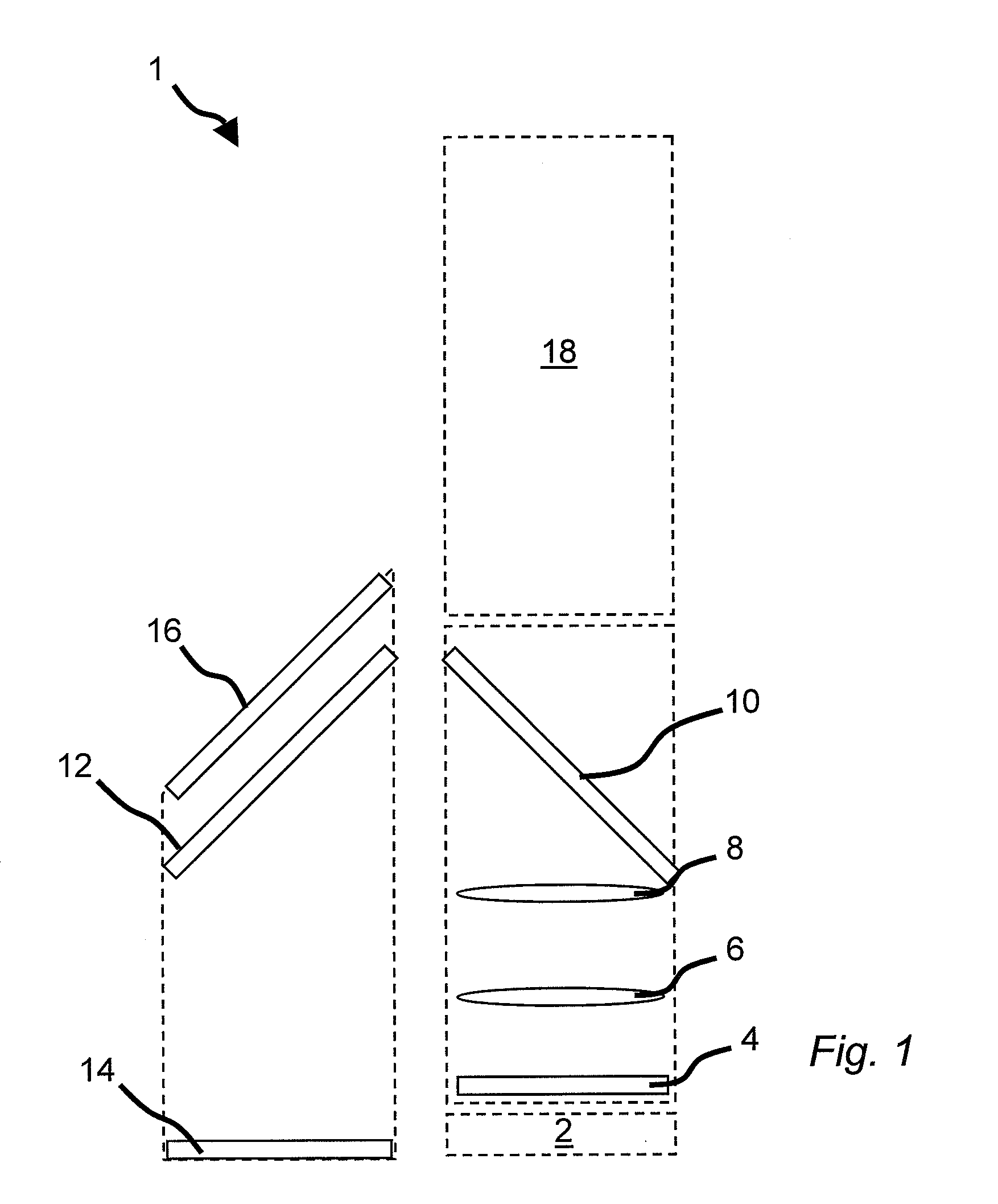

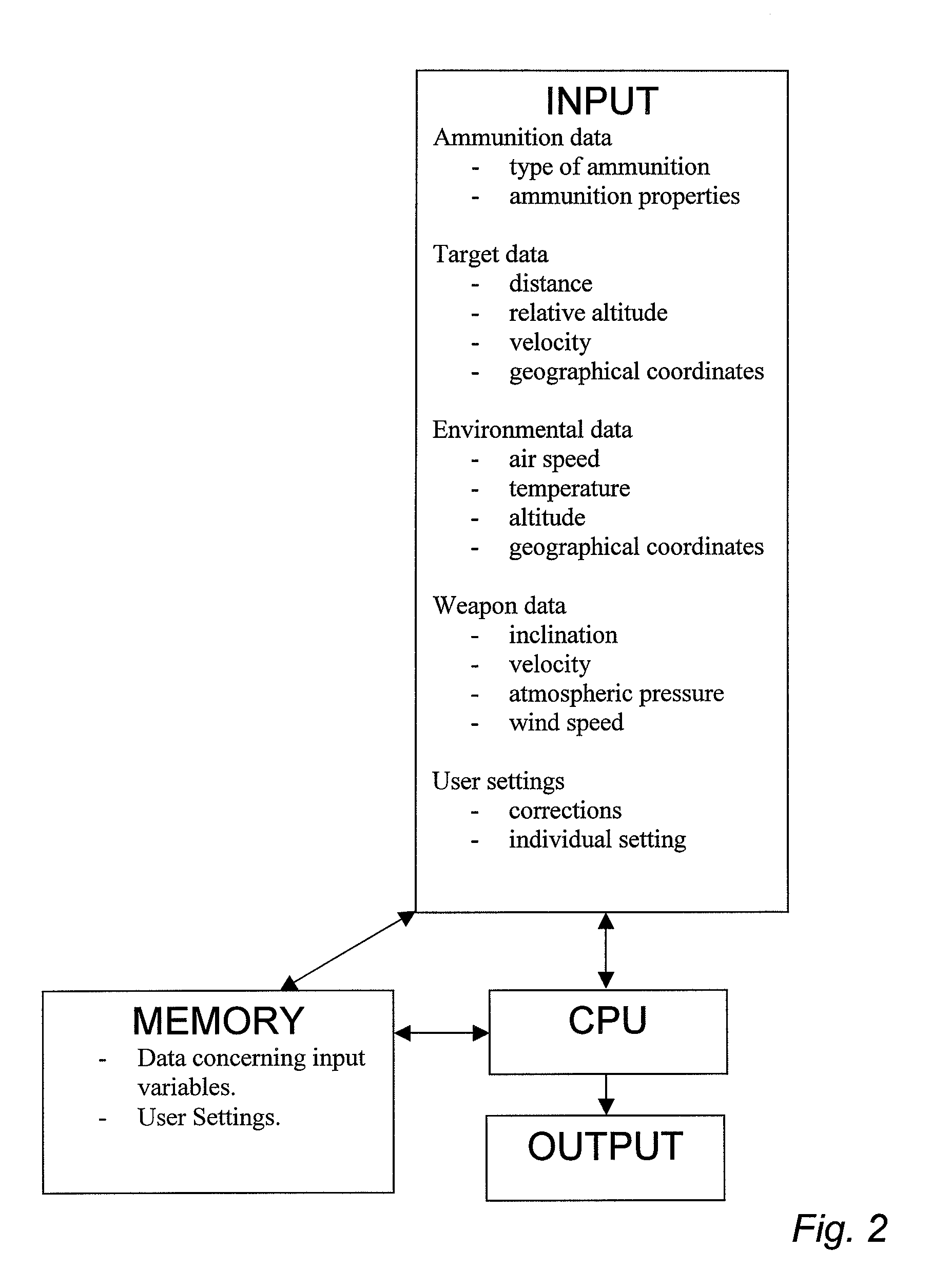

Sight

ActiveUS20090188976A1Increase awarenessReduce consumptionSighting devicesWeapon control systemsDistance to targetComputer science

A self-compensating weapon sight comprisesa housing,partially reflective optics, through which a user may observe a target and receive visually displayed information simultaneously,a light source, for visualization of an aiming point to the user via the partially reflective optics,means for receiving a measure of the distance to the targeta processor, for determining the adequate position of the aiming point, based on the distance to the target, and for controlling the light source to emit light so that the aiming point is visualized at the adequate position,wherein the light source is an array capable of selectively emitting light in well defined locations on its surface.

Owner:AIMPOINT AB

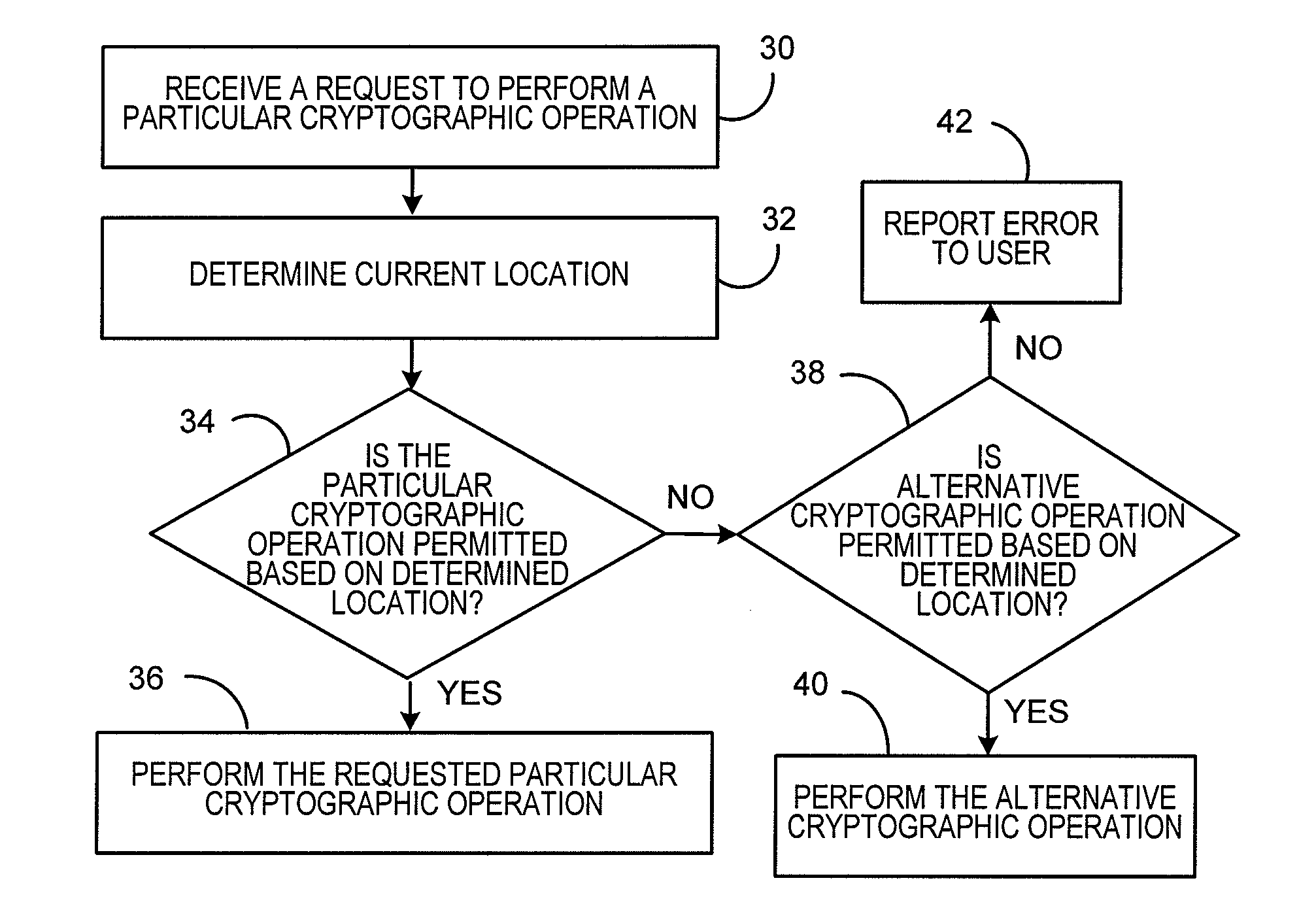

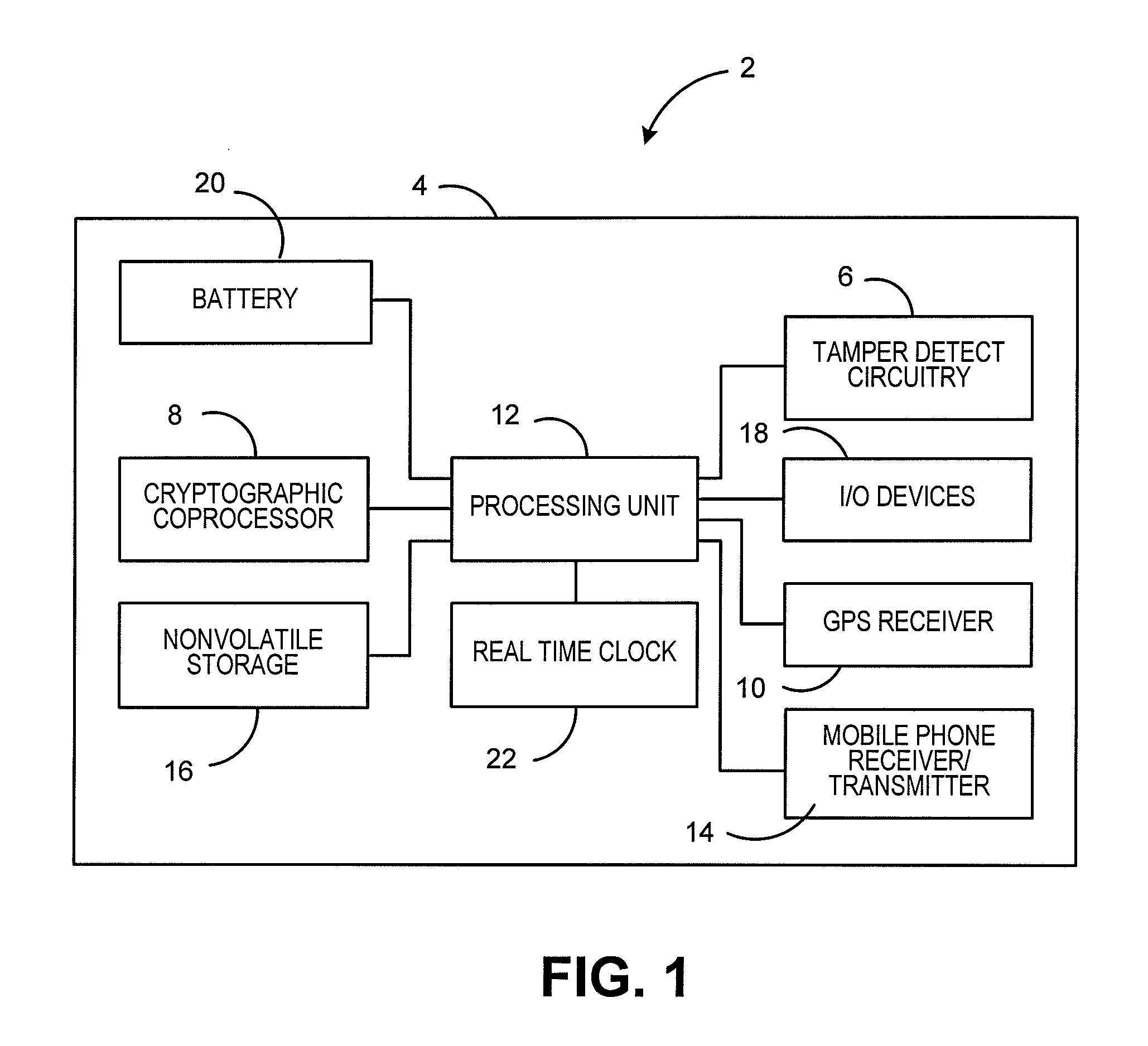

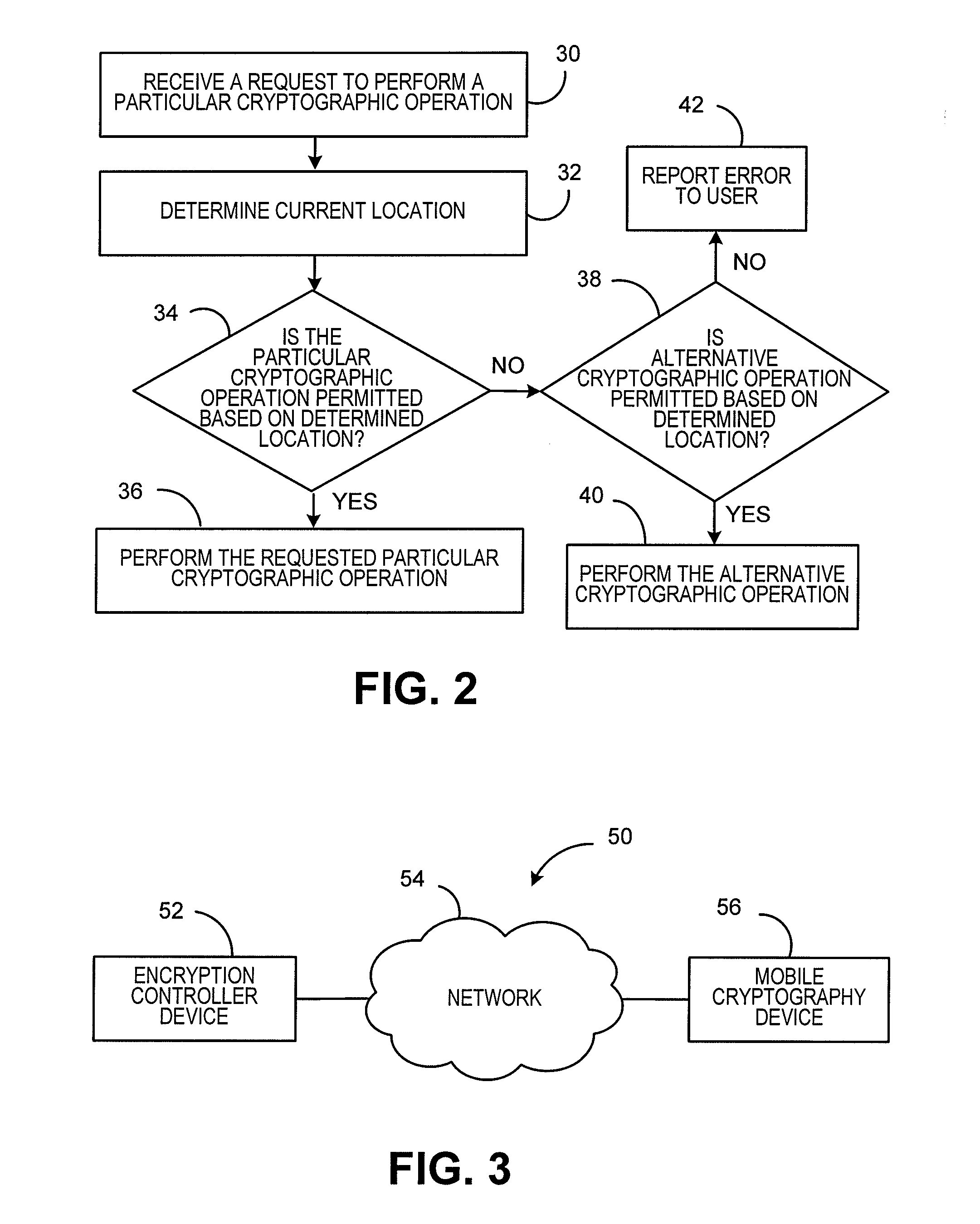

System and method for selectively providing cryptographic capabilities based on location

InactiveUS20110154050A1Unauthorized memory use protectionHardware monitoringMobile electronicsSite selective

A system and method of providing cryptographic functionality includes receiving a request to perform a cryptographic operation in a mobile electronic device, determining whether the cryptographic operation is permitted to be performed by the mobile electronic device based on the current location of the mobile electronic device, and performing the cryptographic operation in the mobile electronic device only if it is determined that the cryptographic operation is permitted.

Owner:PITNEY BOWES INC

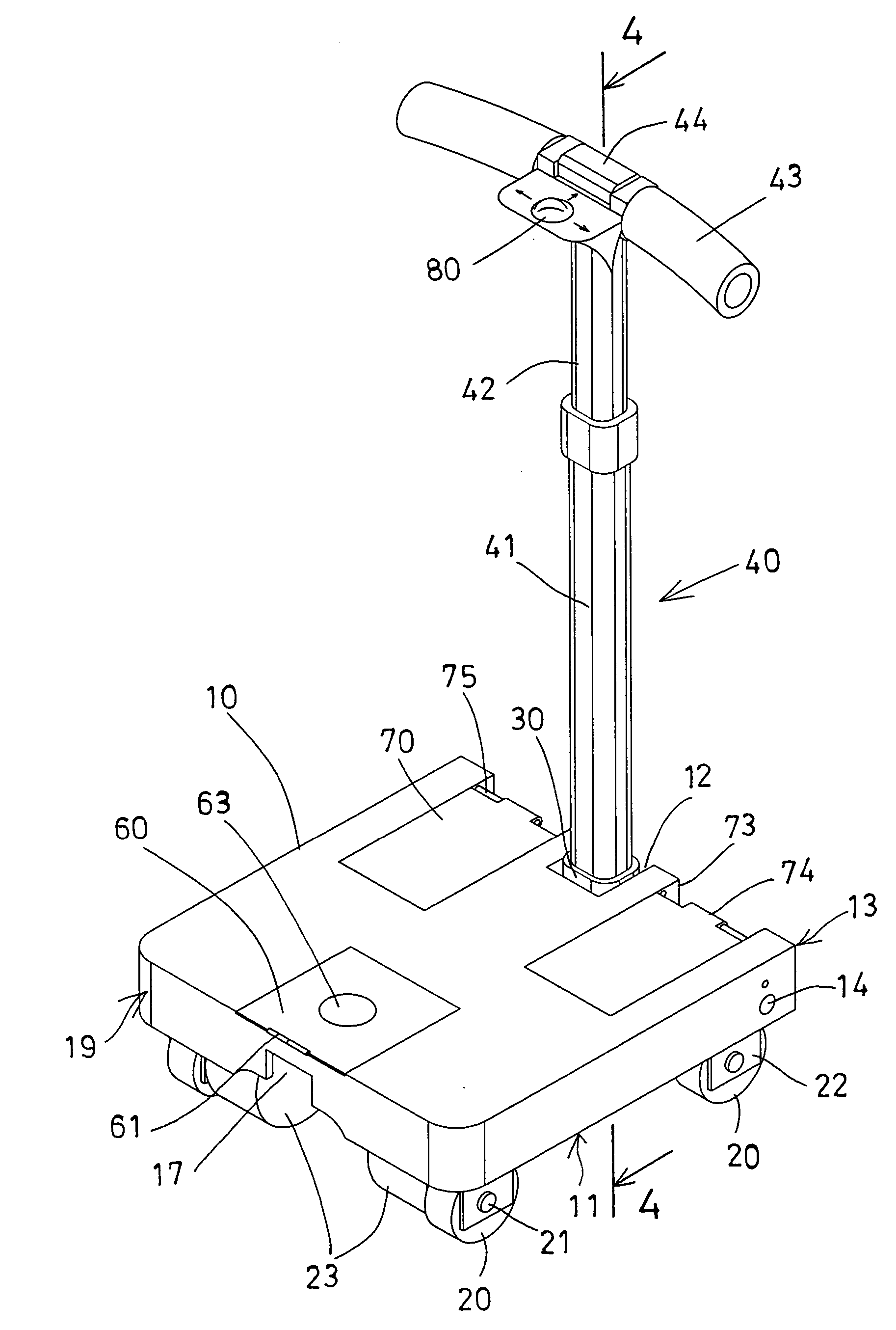

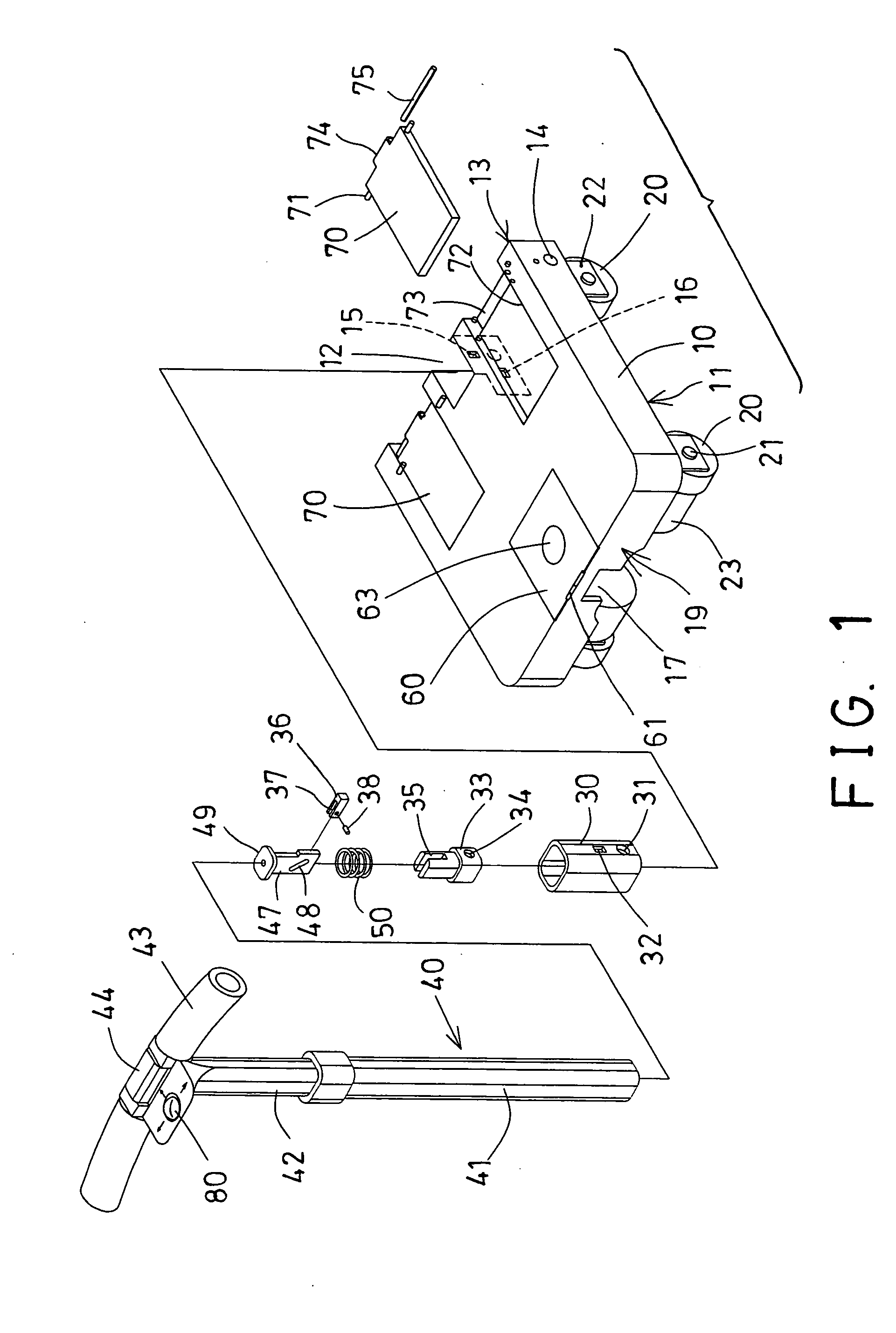

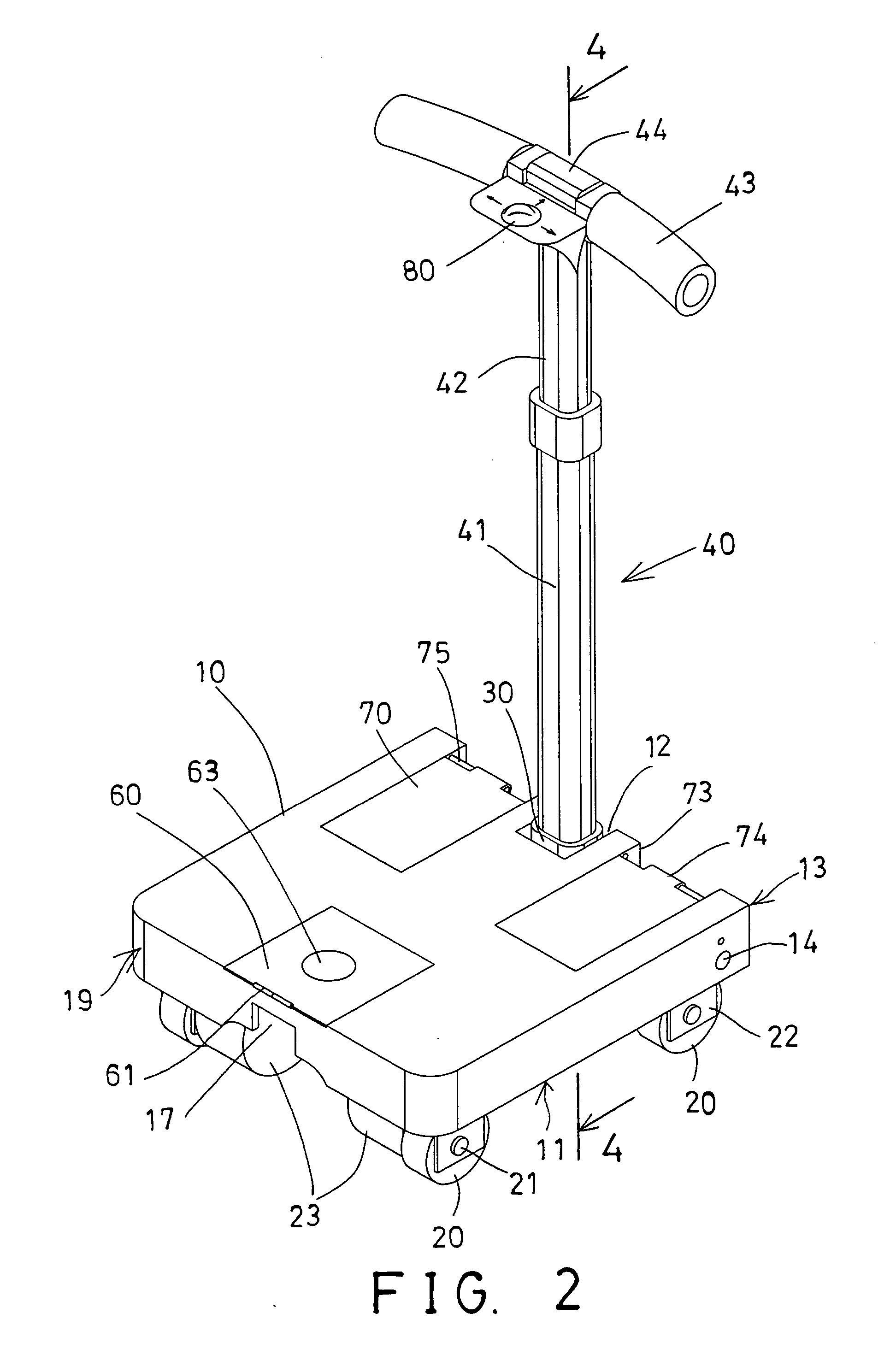

Article carrying cart

InactiveUS20060220334A1Sliding resistanceCarriage/perambulator accessoriesHand carts with one axisActuatorWheel and axle

An article carrying cart includes a platform having a wheel device rotatably attached to a bottom portion with a wheel axle, a handle device pivotally attached to the platform, and a latching device for latching the handle device on the platform at an upwardly extending and working position. One or more step motors may be attached to the platform and coupled to the wheel device, for actuating the wheel device to move the platform. The handle device includes an actuator button for operating the step motors to control the article carrying cart. A latch may selectively latch and lock the barrel and the handle device to the platform at the upwardly extending and working position.

Owner:LIAO LI WEN

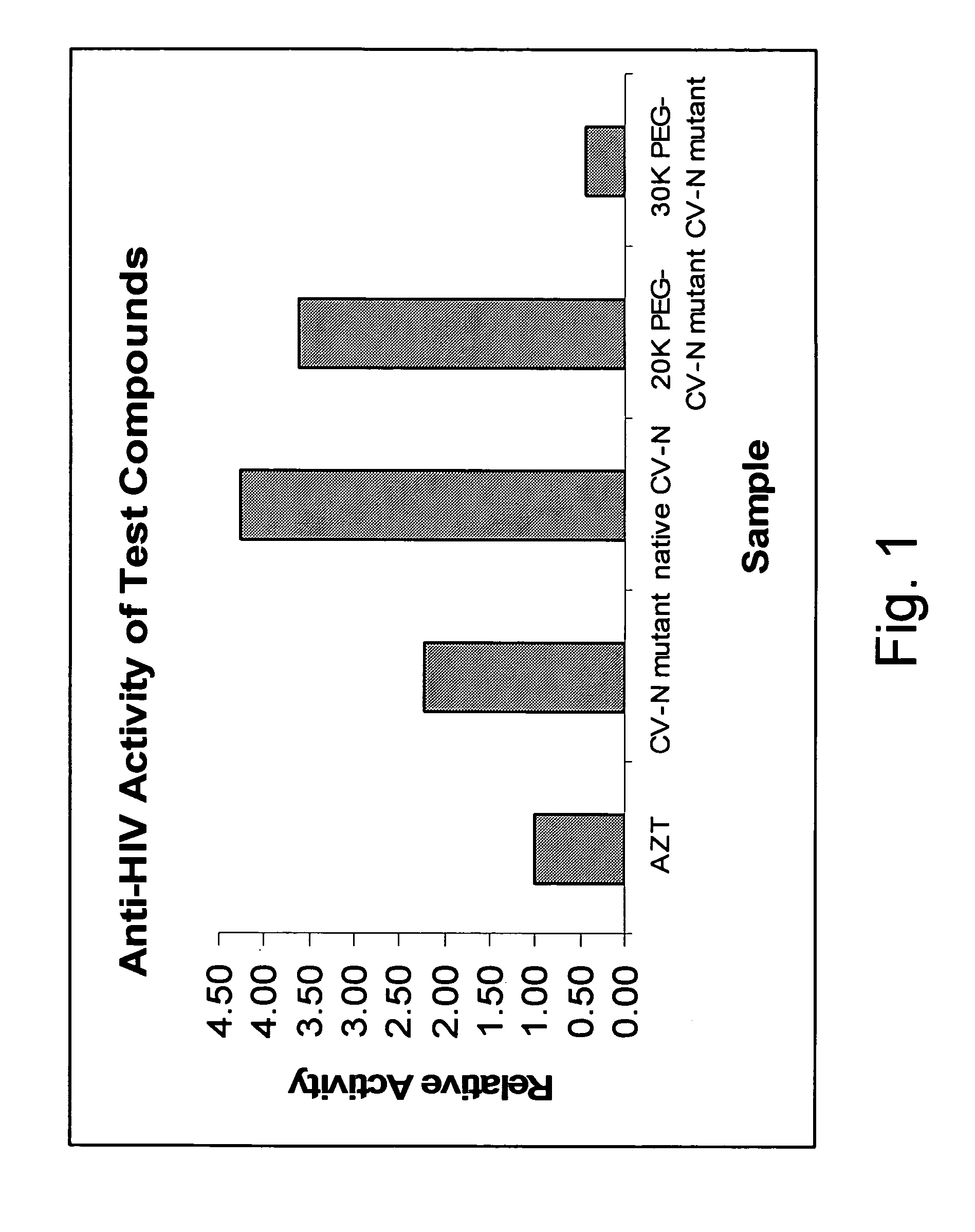

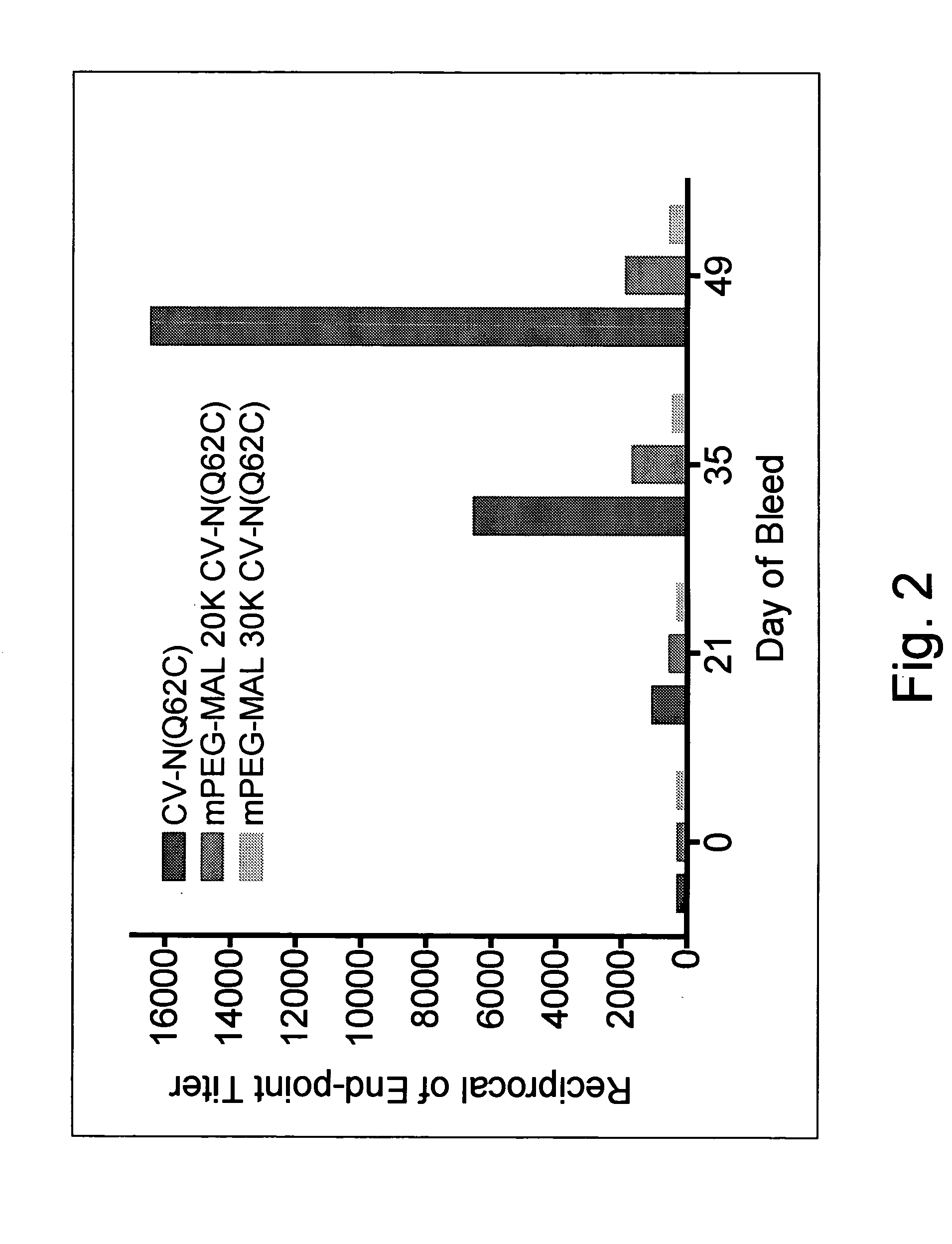

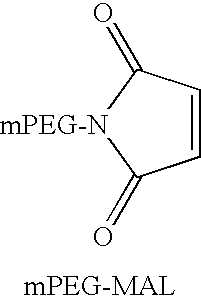

Cyanovirin variant-polymer conjugates

The present invention provides variants of cyanovirin-N and water-soluble polymer conjugates thereof. The cyanovirin-N of the invention are particularly suited for site-selective covalent attachment of one or more water soluble polymers, to provide polymer conjugates of cyanovirin-N variants exhibiting antiviral activity.

Owner:NEKTAR THERAPEUTICS INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com