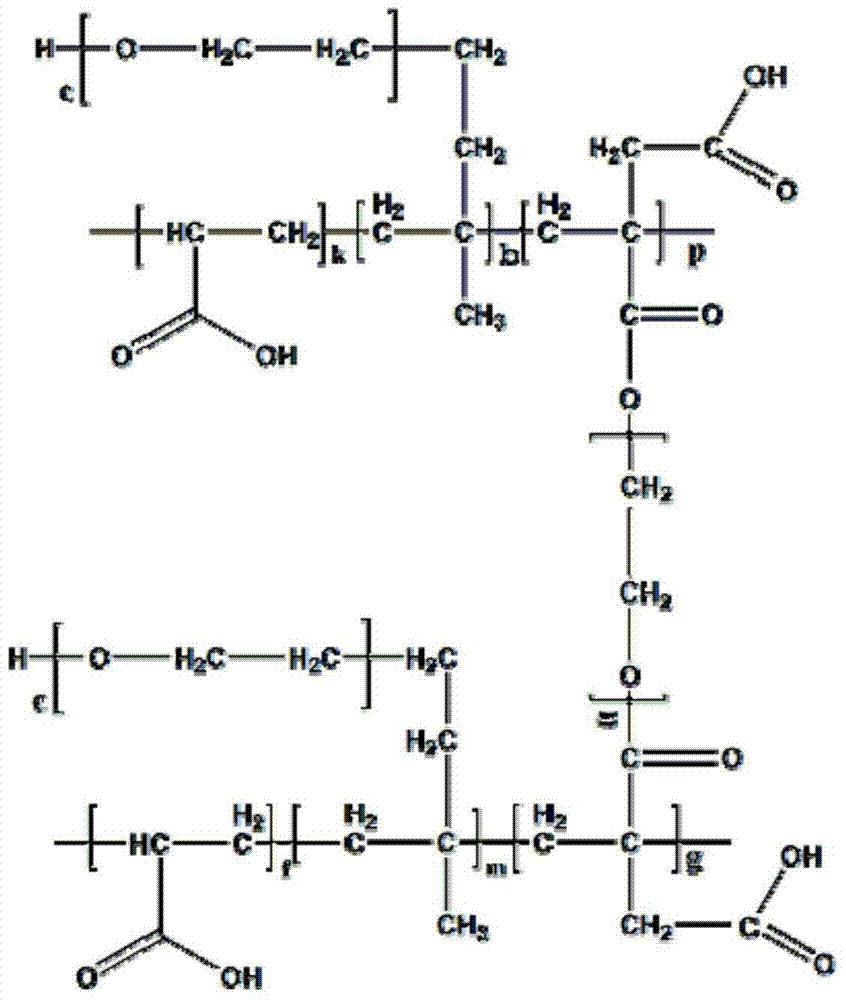

Polyether crosslinked concrete water reducer, and preparation method and application thereof

A concrete water-reducing agent and cross-linking technology, applied in the field of concrete additives, can solve the problems of poor cement adaptability, low water-reducing rate, and large dosage, and achieve the effects of high water-reducing rate, low cost, and low dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

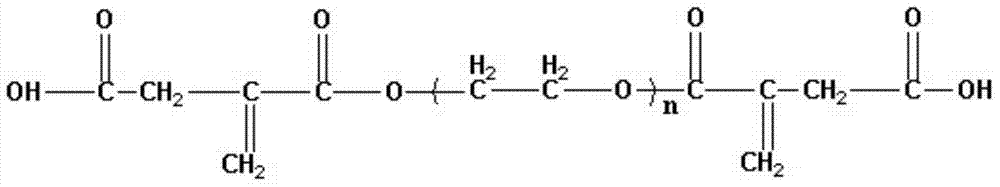

Method used

Image

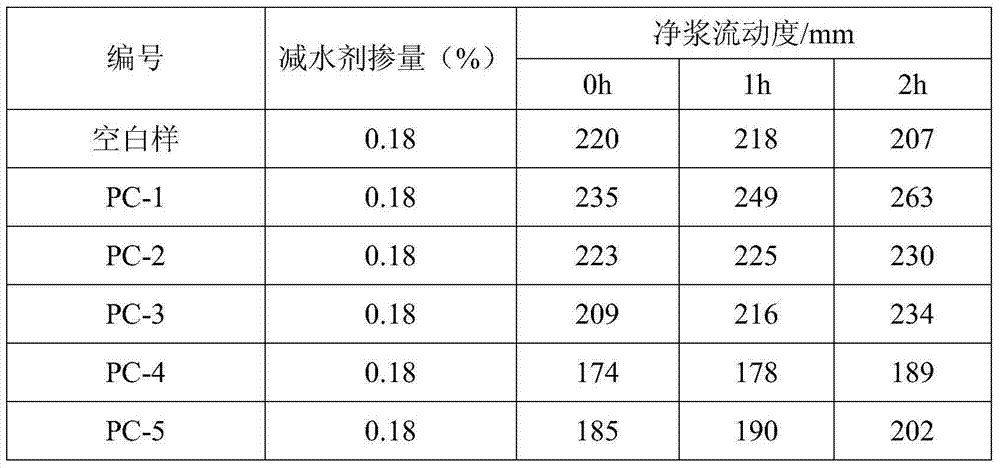

Examples

Embodiment 1

[0033] At the bottom of the three-necked flask, add mass fraction of 0.9% initiator hydrogen peroxide aqueous solution 15g, methallyl alcohol polyoxyethylene ether 20g; crosslinking agent polyethylene glycol bis-itaconate monoester 0.23g, acrylic acid 4g, water 8g Prepare a monomer mixed solution, prepare a reducing agent-chain transfer agent mixed solution with 0.03 g of reducing agent ascorbic acid, 0.14 g of chain transfer agent thioglycolic acid, and 10 g of water; heat the reactor to 50 ° C, and use a peristaltic pump to simultaneously drop monomers Mixed solution and reducing agent-chain transfer agent mixed solution, the total time of dropping the monomer mixed solution is 2h, the monomer mixed solution is dripped before the reducing agent-chain transfer agent mixed solution 0.5h, and the reducing agent-chain transfer agent is mixed After the solution is added dropwise, react at a constant temperature for 3 hours; after the reaction is completed, after the product in the...

Embodiment 2

[0037] At the bottom of the three-necked flask, 10 g of hydrogen peroxide aqueous solution and 25 g of methallyl alcohol polyoxyethylene ether were added with a mass fraction of 1.8% initiator; g to prepare a monomer mixed solution, prepare a reducing agent-chain transfer agent mixed solution with 0.05 g of reducing agent ascorbic acid, 0.2 g of chain transfer agent mercaptopropionic acid, and 14.5 g of water; heat the reactor to 60 ° C, and use a peristaltic pump to drip Add the monomer mixed solution and the reducing agent-chain transfer agent mixed solution. The total time for the addition of the monomer mixed solution is 3 hours. The monomer mixed solution is dripped before the reducing agent-chain transfer agent mixed solution for 1 hour. React for 2 hours; after the reaction is completed, after the product in the reactor is cooled to room temperature, use a 30% NaOH solution to adjust its pH value to 6-8, add water to adjust the solid content to 40%, and obtain the polyet...

Embodiment 3

[0039] At the bottom of the three-necked flask, add mass fraction of 2.3% initiator hydrogen peroxide aqueous solution 25g, methallyl alcohol polyoxyethylene ether 30g; crosslinking agent polyethylene glycol bis-itaconate monoester 0.79g, acrylic acid 5.8g, water Prepare 9.5g of monomer mixed solution, prepare reducing agent-chain transfer agent mixed solution with 0.34g of reducing agent ascorbic acid, 0.42g of chain transfer agent mercaptopropionic acid, and 11.5g of water; heat the reactor to 70°C, and use a peristaltic pump to simultaneously Add the monomer mixed solution and the reducing agent-chain transfer agent mixed solution dropwise. The total time for dropping the monomer mixed solution is 2 hours. The monomer mixed solution is dropped 1.5 hours before the reducing agent-chain transfer agent mixed solution. After the reaction at constant temperature for 5 hours; after the reaction is completed, after the product in the reactor is cooled to room temperature, adjust it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com