Method for grafting anhydride onto cellulosic material in ionic liquid to prepare carboxyl cellulose

A carboxycellulose and ionic liquid technology, applied in the field of biochemical industry, can solve the problems of difficult manipulation and complex preparation process of carboxycellulose, and achieve the effects of easy control, fast and efficient dissolution rate, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

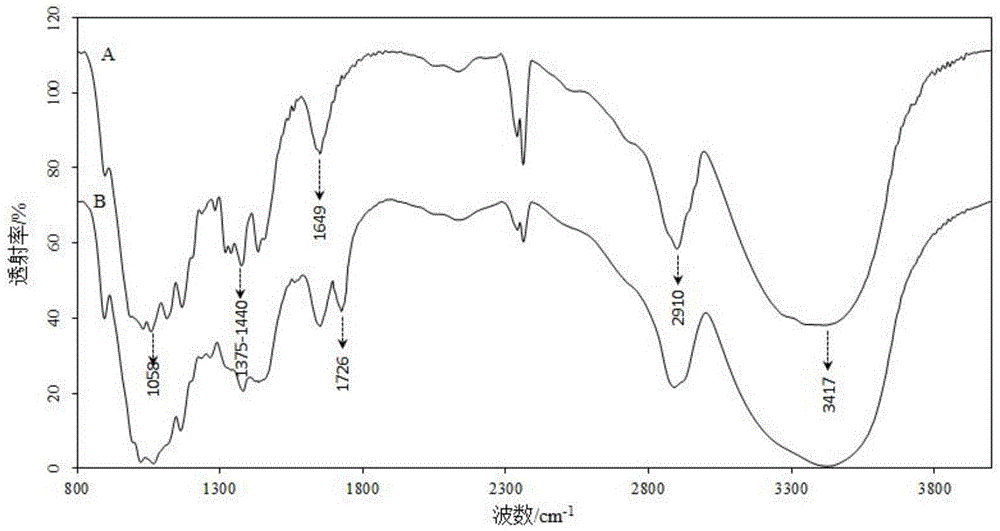

Image

Examples

Embodiment 1

[0027] (1) Take an appropriate amount of microcrystalline cellulose in a beaker, and dry at 80°C for 4-6 hours;

[0028] (2) Weigh 2.25g of ionic liquid [EMIM][DEP] and 0.15g of dried microcrystalline cellulose, successively add them to 20ml iodine measuring bottle A, and carry out oil bath in a collector type constant temperature heating magnetic stirrer. Heat and magnetically stir, react at a constant temperature of 90°C for 1.5 hours to prepare a cellulose solution, at this time the microcrystalline cellulose is completely activated and dissolved in [EMIM][DEP];

[0029] (3) Weigh 1.5g of [EMIM][DEP] and 0.15g of succinic anhydride, add them to 20ml iodine bottle B successively, heat in an oil bath and magnetically stir in a collector type constant temperature heating magnetic stirrer, 40°C React at constant temperature for 1 hour to obtain a succinic anhydride solution;

[0030] (4) Add the above-mentioned cellulose solution and succinic anhydride solution successively in...

Embodiment 2

[0033] (1) Take an appropriate amount of microcrystalline cellulose in a beaker, and dry at 80°C for 4-6 hours;

[0034] (2) Weigh 2.25g of ionic liquid [EMIM][DEP] and 0.15g of dried microcrystalline cellulose, successively add them to 20ml iodine measuring bottle A, and carry out oil bath in a collector type constant temperature heating magnetic stirrer. Heat and magnetically stir, react at a constant temperature of 90°C for 2 hours to prepare a cellulose solution, at this time the microcrystalline cellulose is completely activated and dissolved in [EMIM][DEP];

[0035] (3) Weigh 1.5g of ionic liquid [EMIM][DEP] and 0.15g of succinic anhydride respectively, successively add to 20ml iodine measuring bottle B, carry out oil bath heating and magnetic stirring in the collector type constant temperature heating magnetic stirrer, React at a constant temperature of 40°C for 0.5h to obtain a succinic anhydride solution;

[0036] (4) Add the above-mentioned cellulose solution and su...

Embodiment 3

[0039] (1) Take an appropriate amount of microcrystalline cellulose in a beaker, and dry at 80°C for 4-6 hours;

[0040] (2) Weigh 2.25g of ionic liquid [EMIM][DEP] and 0.15g of dried microcrystalline cellulose, successively add them to 20ml iodine measuring bottle A, and carry out oil bath in a collector type constant temperature heating magnetic stirrer. Heating and stirring with magnetic force, and reacting at a constant temperature of 90°C for 2 hours to obtain a cellulose solution;

[0041] (3) Weigh 1.5g of ionic liquid [EMIM][DEP] and 0.15g of maleic anhydride, successively add to 20ml iodine measuring bottle B, heat in an oil bath and magnetically stir in a collector type constant temperature heating magnetic stirrer , constant temperature reaction at 40°C for 0.5h to obtain a maleic anhydride solution;

[0042] (4) Add the above-mentioned cellulose solution and maleic anhydride solution to a 20ml iodine flask C successively, heat in an oil bath and magnetically stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com