Modified naphthalene water reducer containing waste residue generated in phenol production process

A naphthalene-based water-reducer and production process technology, applied in the field of modified naphthalene-based water-reducers, to achieve the effect of improving slump, solving environmental problems, and creating economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

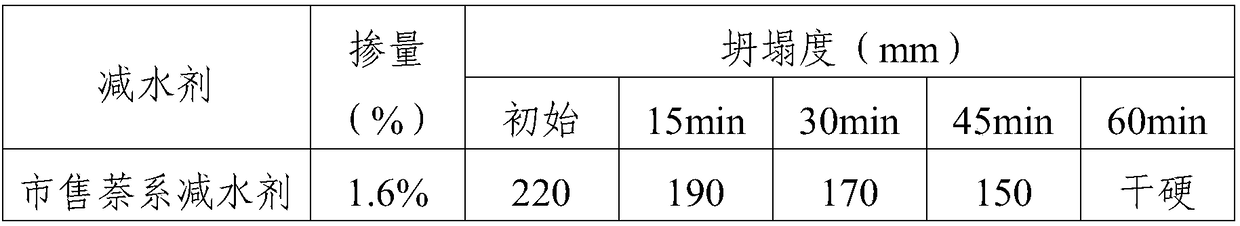

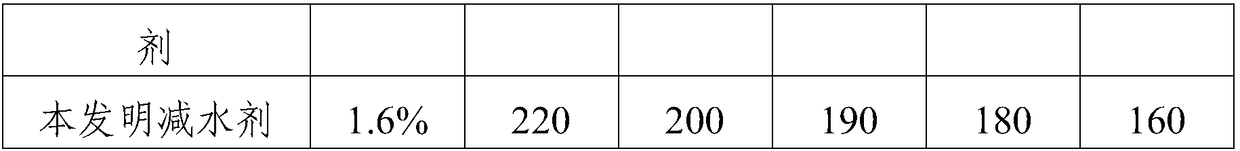

Examples

Embodiment 1

[0027] A modified naphthalene-based water reducer containing waste residues in the production process of phenols, which contains the following components in parts by weight: 270 parts of industrial naphthalene, 250 parts of industrial concentrated sulfuric acid, and 70 parts of waste residues in the production process of phenols 180 parts of formaldehyde with a concentration of 37%, 500 parts of liquid caustic soda, and 30 parts of water.

[0028] The above-mentioned modified naphthalene-based water reducer containing waste residues in the production process of phenols, its preparation method comprises the following steps:

[0029] (1) Take the above-mentioned raw materials;

[0030] (2) Add industrial naphthalene into a four-necked flask, heat it to 150°C and melt it, then raise the temperature to 155-160°C, add concentrated sulfuric acid dropwise while stirring, control the drop rate, finish adding dropwise in 30 minutes, and keep warm for 3.5 minutes after dropping h, dete...

Embodiment 2

[0034] A modified naphthalene-based water reducer containing waste residues in the production process of phenols, which contains the following components in parts by weight: 260 parts of industrial naphthalene, 240 parts of industrial concentrated sulfuric acid, and 65 parts of waste residues in the production process of phenols 175 parts of formaldehyde, 480 parts of liquid caustic soda, and 25 parts of water with a concentration of 37%.

[0035] The above-mentioned modified naphthalene-based water reducer containing waste residues in the production process of phenols, its preparation method comprises the following steps:

[0036] (1) Take the above-mentioned raw materials;

[0037] (2) Add industrial naphthalene into a four-necked flask, heat it to 150°C and melt it, then raise the temperature to 155-160°C, add concentrated sulfuric acid dropwise while stirring, control the drop rate, finish adding dropwise in 30 minutes, and keep warm for 4 hours after dropping , detect th...

Embodiment 3

[0041] A modified naphthalene-based water reducer containing waste residues in the production process of phenols, which contains the following components in parts by weight: 280 parts of industrial naphthalene, 260 parts of industrial concentrated sulfuric acid, and 75 parts of waste residues in the production process of phenols 185 parts of formaldehyde, 530 parts of liquid caustic soda, and 35 parts of water with a concentration of 37%.

[0042] The above-mentioned modified naphthalene-based water reducer containing waste residues in the production process of phenols, its preparation method comprises the following steps:

[0043] (1) Take the above-mentioned raw materials;

[0044] (2) Add industrial naphthalene into a four-necked flask, heat it to 150°C and melt it, then raise the temperature to 155-160°C, add concentrated sulfuric acid dropwise while stirring, control the drop rate, finish dropping in 30 minutes, and keep warm for 4.5 minutes after dropping h, detect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com