High-yield peanut cultivation method for relieving successive cropping obstacle

A continuous cropping obstacle, peanut technology, applied in the field of peanut high-yield cultivation method, can solve the problems of poor viability of beneficial microorganisms, incomplete killing, poor effect, etc., and achieves improved disinfection effect, improved soil disinfection effect, and multiplied technical effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

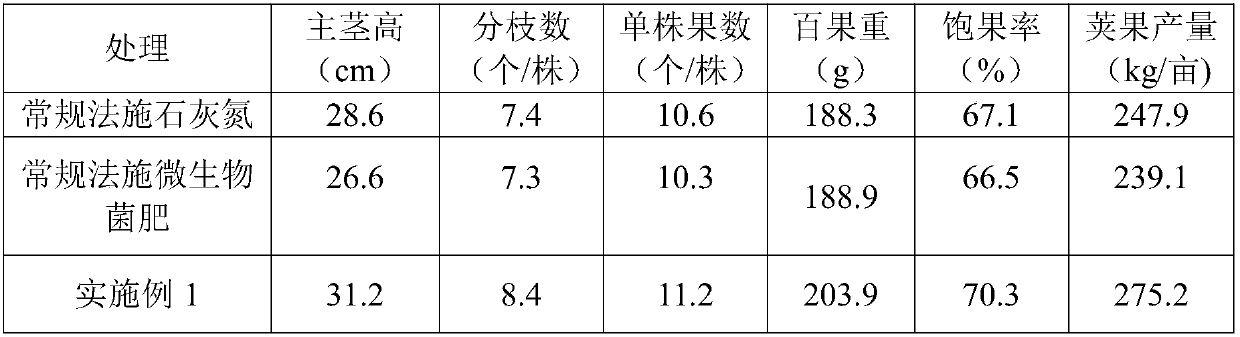

Embodiment 1

[0036] A high-yield cultivation method for peanuts that removes continuous cropping obstacles, is characterized in that it specifically includes the following steps:

[0037] (1) Soil preparation: 25 days before peanut sowing, spread 15kg of lime nitrogen and 10kg of cotton mill per mu, cultivate the land, plow 30cm deep, and after 2 times of rotary tillage, fully crush the soil for leveling;

[0038] (2) Ridging and mulching: according to the conventional planting specifications of peanuts, ridges are mulched, and drip irrigation pipes are laid at the same time;

[0039] (3) Drip irrigation: drip irrigation water into the soil through the drip irrigation pipe to control the soil moisture, and control the water to penetrate to a depth of more than 20cm;

[0040] (4) Sowing holes: 2 days before sowing the peanuts, make sowing holes on the film according to the conventional hole spacing, releasing toxic gas;

[0041] (5) Sowing: control the sowing depth to 2cm, cover the sowing...

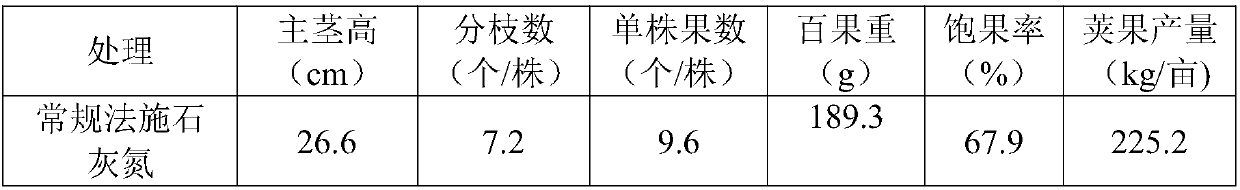

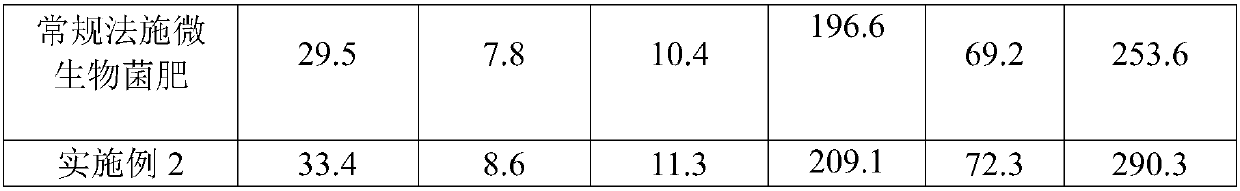

Embodiment 2

[0044] A high-yield cultivation method for peanuts that removes continuous cropping obstacles, is characterized in that it specifically includes the following steps:

[0045] (1) Soil preparation: 28 days before peanut sowing, spread 17.5kg of lime nitrogen and 15kg of cotton mill per mu, cultivate the land, plow 28cm deep, and after 3 times of rotary tillage, fully crush the soil for leveling;

[0046] (2) Ridging and mulching: Ridging and mulching according to the conventional peanut planting specifications, and laying drip irrigation pipes at the same time;

[0047] (3) Drip irrigation: drip irrigation water into the soil through the drip irrigation pipe to control the soil moisture, and control the water to penetrate to a depth of more than 20cm;

[0048] (4) Sowing holes: 3 days before sowing the peanuts, make sowing holes on the film according to the conventional hole spacing to release toxic gas;

[0049] (5) Sowing: control the sowing depth of 2.8cm, cover the sowing ...

Embodiment 3

[0052] A high-yield cultivation method for peanuts that removes continuous cropping obstacles, is characterized in that it specifically includes the following steps:

[0053] (1) Soil preparation: 30 days before peanut sowing, spread 16.3kg of lime nitrogen and 12.5kg of cotton mill per mu, cultivate the land, plow 30cm deep, and after 2 times of rotary tillage, fully crush the soil for leveling;

[0054] (2) Ridging and mulching: according to the conventional planting specifications of peanuts, ridges are mulched, and drip irrigation pipes are laid at the same time;

[0055] (3) Drip irrigation: drip irrigation water into the soil through the drip irrigation pipe to control the soil moisture, and control the water to penetrate to a depth of more than 20cm;

[0056] (4) Sowing holes: 3 days before sowing the peanuts, make sowing holes on the film according to the conventional hole spacing, and release toxic gas;

[0057] (5) Sowing: control the sowing depth of 2.8cm, cover the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com