Waste colophony used for modifying naphthalene water reducer during binding agent production

A naphthalene-based water-reducing agent and a production process technology, applied in the field of preparation of modified naphthalene-based water-reducing agent, can solve the problems of difficult separation and purification, high energy consumption, inability to discharge, etc., to achieve the effect of improving slump and increasing The effect of the number of branches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

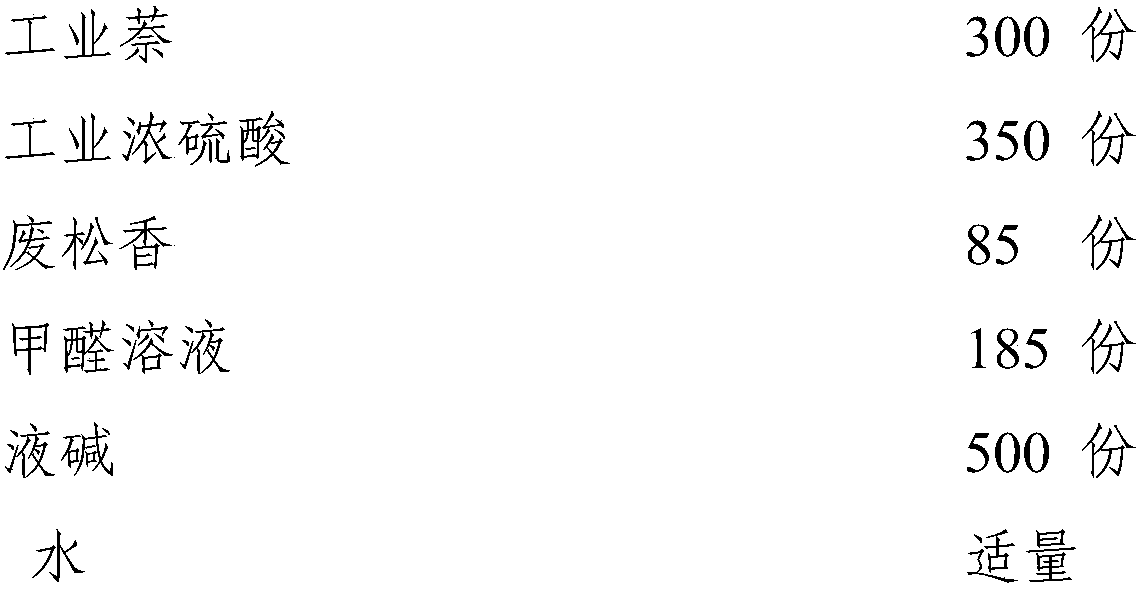

[0025] A kind of waste rosin in the adhesive production process is used to modify the naphthalene-based water-reducer, and the waste rosin in the adhesive production process is used to modify the naphthalene-based water-reducer. It is made of the following raw materials in parts by weight:

[0026]

[0027]

[0028] The waste rosin in the adhesive production process is used for the preparation method of modified naphthalene-based water reducer, comprising the following steps:

[0029] S1. Add the industrial naphthalene of the weight component into the four-necked flask, heat it to 150°C and melt it. After melting, add concentrated sulfuric acid and water dropwise while stirring at 160°C. After 30 minutes, keep it warm for 4 hours. , detect the acidity value of the material;

[0030] S2. After the heat preservation reaction is completed, lower the temperature to 120°C, add an appropriate amount of water according to the acidity value, and hydrolyze for 30 minutes. After t...

Embodiment 2

[0033] A kind of waste rosin in the adhesive production process is used to modify the naphthalene-based water-reducer, and the waste rosin in the adhesive production process is used to modify the naphthalene-based water-reducer. It is made of the following raw materials in parts by weight:

[0034]

[0035] The waste rosin in the adhesive production process is used for the preparation method of modified naphthalene-based water reducer, comprising the following steps:

[0036] S1. Add the industrial naphthalene of the weight component into the four-necked flask, heat it to 145°C and melt it. After melting, add concentrated sulfuric acid and water dropwise at 155°C while stirring, drop it for 30 minutes, and keep it warm for 3 hours after dropping it. , detect the acidity value of the material;

[0037] S2. After the heat preservation reaction is completed, lower the temperature to 125°C, add an appropriate amount of water according to the acidity value, and hydrolyze for 35 ...

Embodiment 3

[0040] A kind of waste rosin in the adhesive production process is used to modify the naphthalene-based water-reducer, and the waste rosin in the adhesive production process is used to modify the naphthalene-based water-reducer. It is made of the following raw materials in parts by weight:

[0041]

[0042] The waste rosin in the adhesive production process is used for the preparation method of modified naphthalene-based water reducer, comprising the following steps:

[0043] S1. Add the industrial naphthalene of the weight component into the four-necked flask, heat it to 145°C and melt it. After melting, add concentrated sulfuric acid and water dropwise at 165°C while stirring, drop it in 45 minutes, and keep it warm for 5 hours after dropping it. , detect the acidity value of the material;

[0044] S2. After the heat preservation reaction is completed, lower the temperature to 115°C, add an appropriate amount of water according to the acidity value, and hydrolyze for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com