Concrete preparation process

A preparation process and concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of improving anti-cracking and anti-seepage performance, prolonging hydration and hardening time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

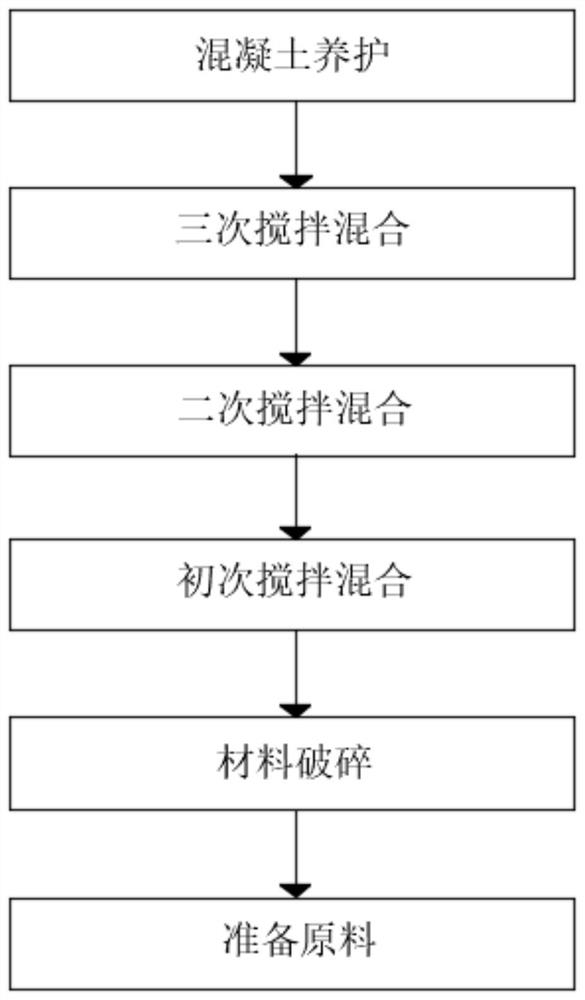

[0044] see figure 1 , the invention provides a kind of concrete preparation technology, wherein technical scheme is as follows:

[0045] Described concrete preparation process specifically comprises the following steps:

[0046] S1. Prepare raw materials: take 375 parts of cement, 65 parts of fiber filler, 12 parts of retarder, 575 parts of sand, 38 parts of additives, 75 parts of silicon fume, 75 parts of fly ash, and 45 parts of surfactant according to the parts by mass 275 parts of water;

[0047] S2. Material crushing: fully mix cement, fiber filler, silica fume and fly ash according to the parts by weight, and then put them into a crusher for crushing to reach the specifications for use;

[0048] S3, initial stirring and mixing: select crushed cement, fiber filler, silica fume and fly ash according to the parts by weight and mix them evenly with water and sand according to the parts by weight, and fully stir through the mixer to obtain the first mixture;

[0049] S4. ...

Embodiment 3

[0061] see figure 1 , the invention provides a kind of concrete preparation technology, wherein technical scheme is as follows:

[0062] Described concrete preparation process specifically comprises the following steps:

[0063] S1. Prepare raw materials: take 450 parts of cement, 80 parts of fiber filler, 13 parts of retarder, 650 parts of sand, 35 parts of additives, 90 parts of silicon fume, 90 parts of fly ash, and 60 parts of surfactant according to the parts by mass 250 parts of water;

[0064] S2. Material crushing: fully mix cement, fiber filler, silica fume and fly ash according to the parts by weight, and then put them into a crusher for crushing to reach the specifications for use;

[0065] S3, initial stirring and mixing: select crushed cement, fiber filler, silica fume and fly ash according to the parts by weight and mix them evenly with water and sand according to the parts by weight, and fully stir through the mixer to obtain the first mixture;

[0066] S4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com