Concrete expansion agent

An expansion agent and concrete technology, applied in the field of concrete expansion agent, can solve the problems of inability to adapt to the development of concrete strength, insufficient compensation for shrinkage, low expansion rate, etc., to improve long-term volume stability, overall compactness improvement, porosity reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

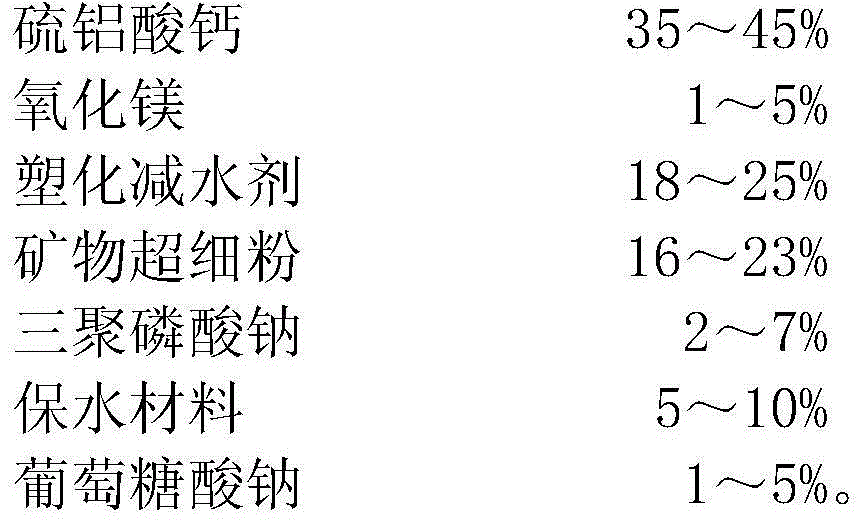

Method used

Image

Examples

Embodiment 1

[0032] First, add 5kg of magnesium oxide to 23kg of fly ash with a specific surface area of 700㎡ / kg, start the forced mixer, stir for 5 minutes to make it evenly mixed, then start the mixer, and add 18kg of powdered naphthalene-based water reducing agent, 4kg sodium tripolyphosphate, 10kg methylcellulose, 35kg calcium sulfoaluminate and 5kg sodium gluconate; continue to stir for 40 minutes, stir evenly, and finally pack it with a woven bag lined with a plastic bag, which is the finished product.

Embodiment 2

[0034] First, add 4kg of magnesium oxide to 18kg of mineral powder with a specific surface area of 800㎡ / kg, start the forced mixer, stir for 6 minutes to make it evenly mixed, then start the mixer, and add 23kg of powdered melamine-based water reducer after an interval of 2 minutes , 6kg sodium tripolyphosphate, 8kg hydroxyethyl methylcellulose, 37kg calcium sulfoaluminate and 4kg sodium gluconate; continue to stir for 40 minutes, stir evenly, and finally pack it in a woven bag with a lined plastic bag, which is the finished product .

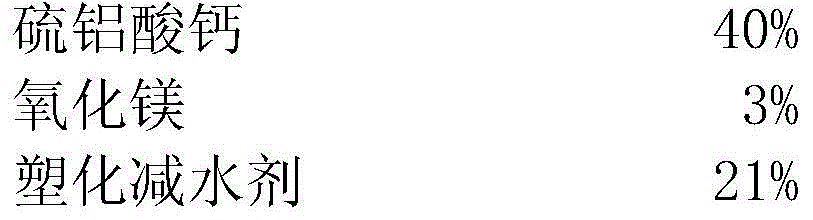

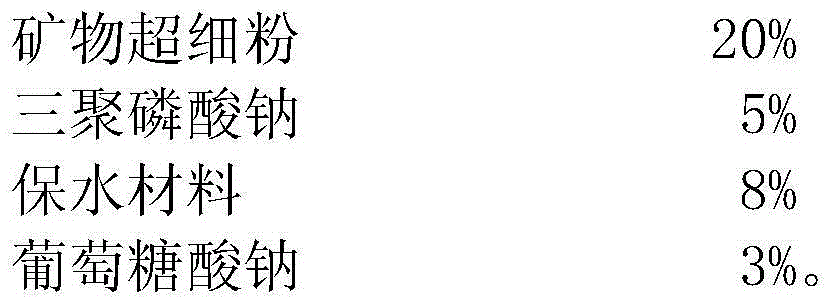

Embodiment 3

[0036] First, add 3kg of magnesium oxide to 20kg of fly ash with a specific surface area of 850㎡ / kg, start the forced mixer, stir for 7 minutes to make it evenly mixed, then start the mixer, and add 21kg of powdered naphthalene-based Aqua, 5kg sodium tripolyphosphate, 8kg hydroxypropyl methylcellulose, 40kg calcium sulfoaluminate and 3kg sodium gluconate; continue to stir for 40 minutes, stir evenly, and finally pack it in a woven bag with a lined plastic bag, that is, for the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com