Construction technology for anti-crack and waterproof structure of post-cast strip

A technology of construction technology and waterproof structure, which is applied in the field of construction, can solve the problems of concrete siltation in the post-casting belt, and achieve the effects of extending water seepage lines, ensuring construction quality, and good drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

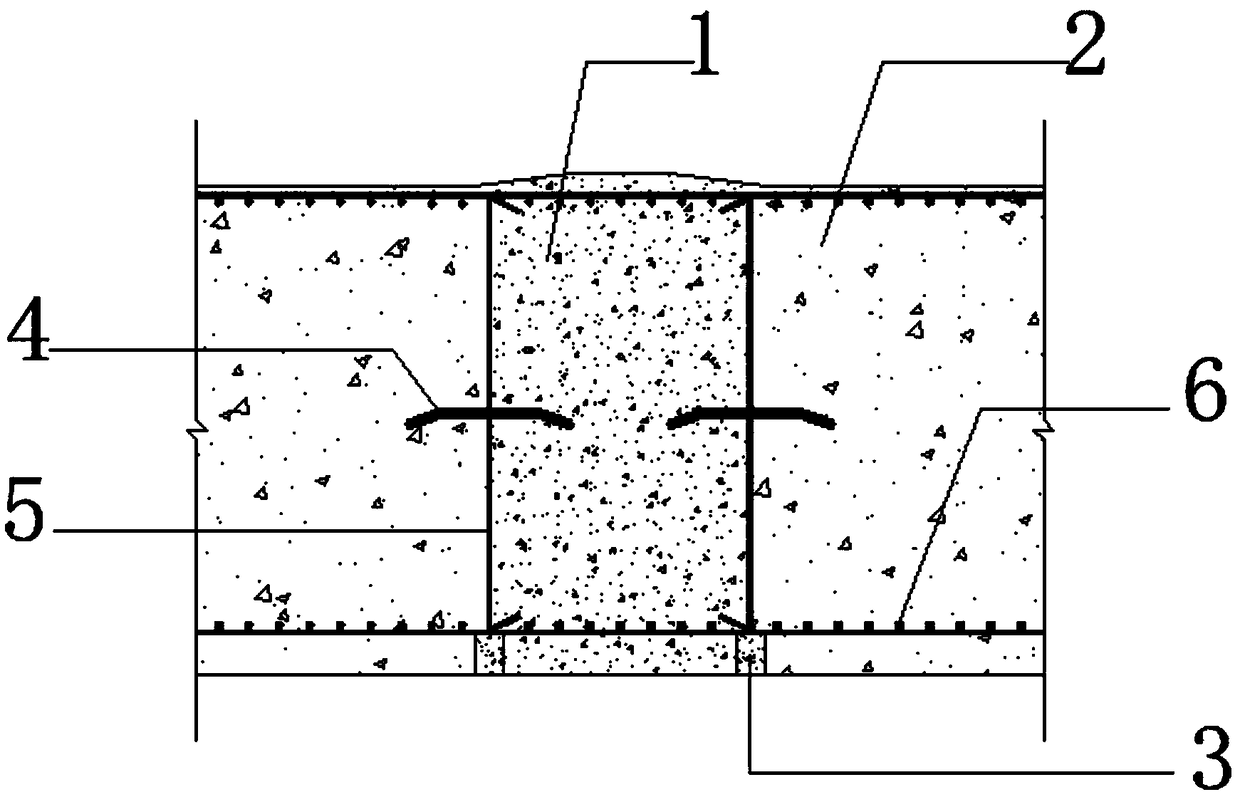

[0034] Such as figure 1 Shown is a post-pouring belt crack-resistant waterproof structure construction technology, the specific construction steps are as follows,

[0035] Step 1, material preparation:

[0036] Ordinary waterproof concrete 2 for construction, micro-expansion waterproof concrete 1, waterproof steel plate 4, structural steel bars 6, fine stone waterproof concrete, B steel bars, dense-hole barbed wire, wooden squares, etc.;

[0037] Step 2, fine stone waterproof concrete strip pouring:

[0038] After the base layer is cleaned up, make molds with wooden squares on both sides of the post-casting belt, and pour a fine stone waterproof concrete strip 3 with a width of 3 cm, a height equal to the thickness of the steel bar protection layer in the lower layer, and a length along the length of the post-casting belt;

[0039] Step 3: Binding of post-cast steel bars, dense-hole steel wire mesh, water-stop steel plate installation, and hanging formwork:

[0040] After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com