Anti-cracking waterproof construction method for post-poured strip

A construction method and technology of post-casting belts, which are applied to building components, building insulation materials, buildings, etc., can solve the problems of concrete deposition, concrete cracking, and increased labor cleaning in post-casting belts, and achieve resistance to uneven settlement and good resistance Crack and anti-seepage effect to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the specification, drawings and embodiments.

[0025] A post-pouring belt anti-crack and waterproof construction method. Before construction, material preparation is required.

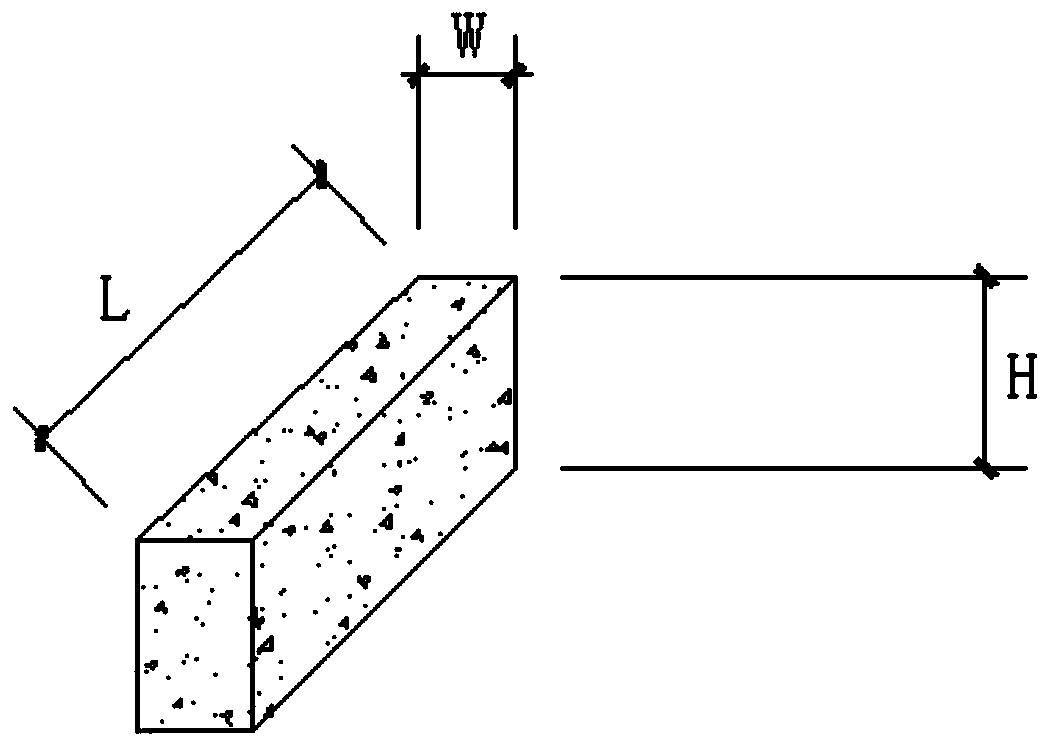

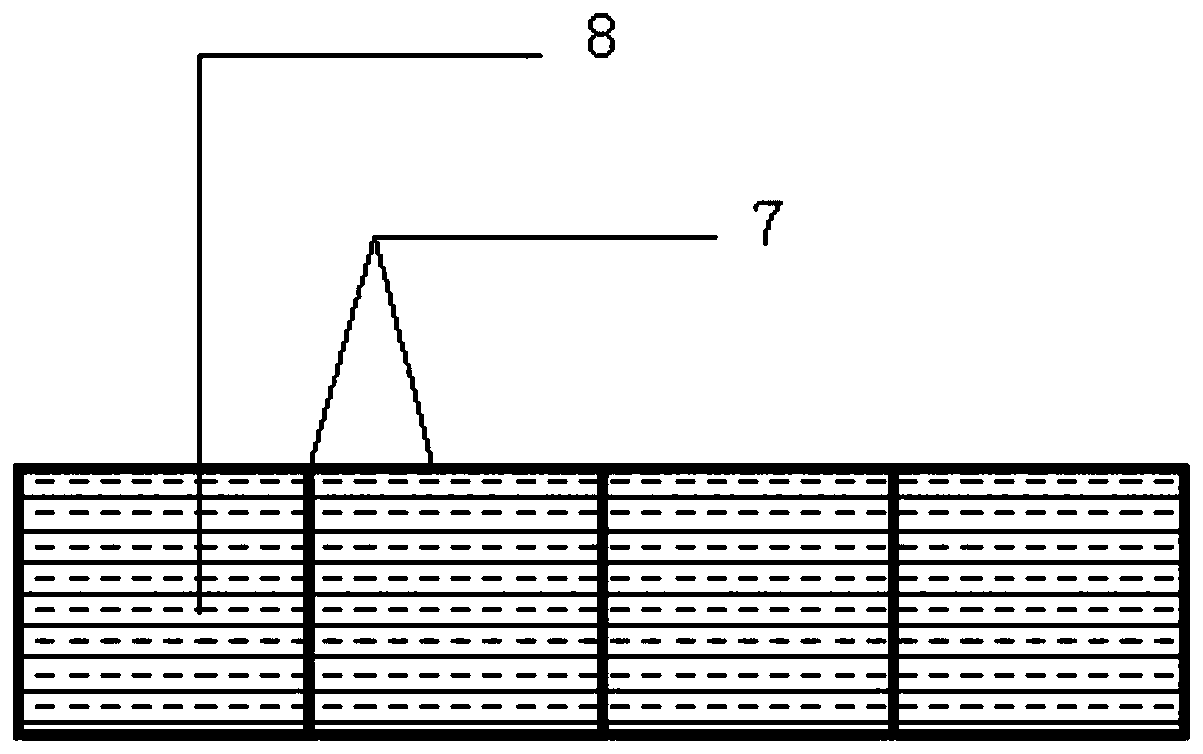

[0026] Preparation of fine stone waterproof concrete for construction 1, ordinary waterproof concrete 5, micro-expansion waterproof concrete 6 (one level higher than ordinary waterproof concrete strength), 3mm thick water-stop steel plate 4, structural steel bar 3, B8 steel bar, dense hole wire mesh 8, template , Mu Fang, etc.

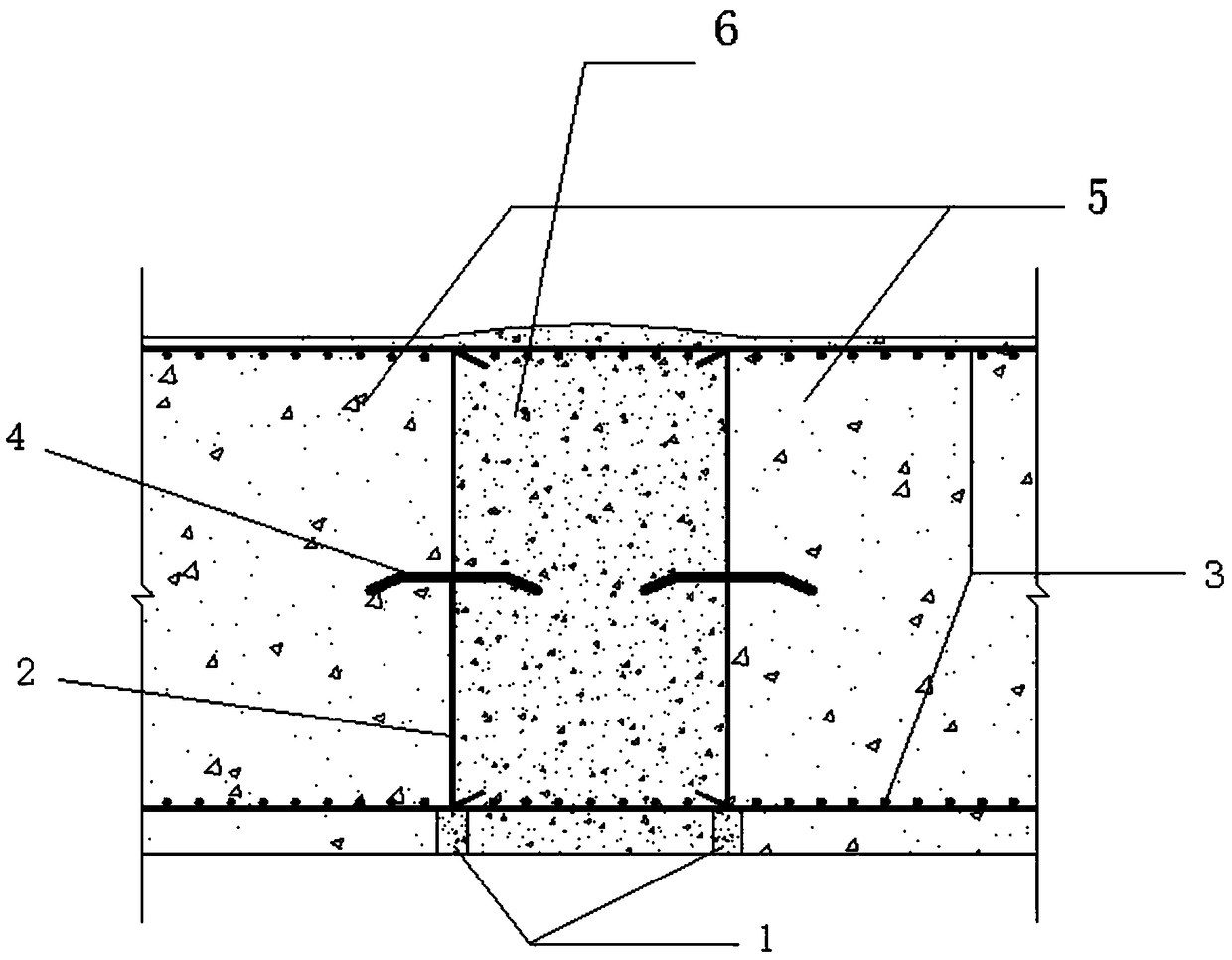

[0027] Such as figure 1 As shown, the construction steps are as follows:

[0028] 1) Pouring of fine stone waterproof concrete strip 1

[0029] After the base layer is cleaned, make molds with wooden squares on both sides of the post-pouring belt. The pouring width is 3cm, the height is the same as the thickness of the lower steel protection layer, and the length is the fine stone waterproof concrete strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com