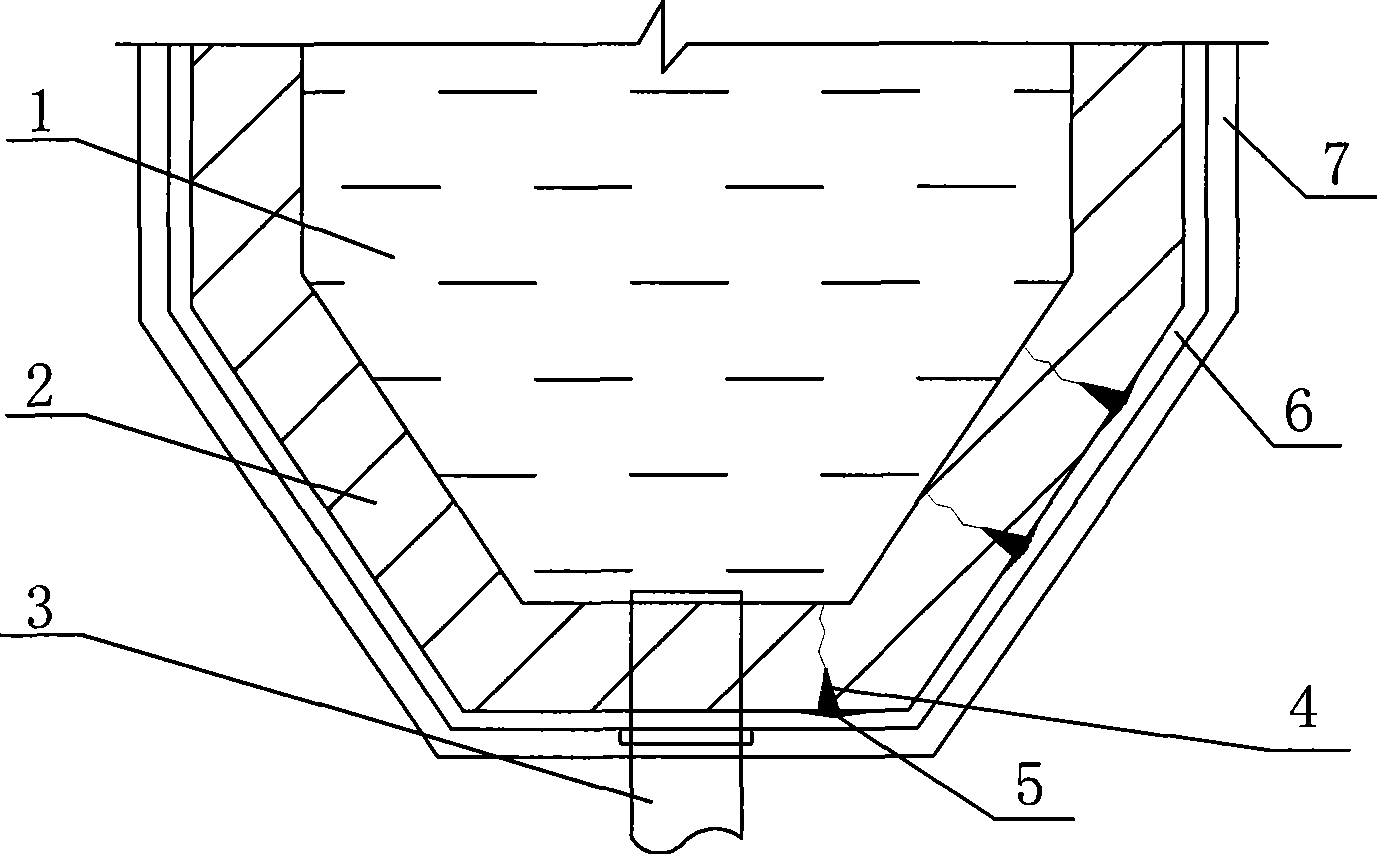

Method for compensation and anti-permeation of temperature difference cracks of ground concrete high-temperature pool

A temperature difference compensation, concrete technology, applied in swimming pools, buildings, building maintenance and other directions, can solve the temperature difference cracks without providing effective and reliable control and solution technology, the pool wall temperature difference has not been treated and improved, the temperature stress can not be effectively It can reduce the temperature stress of the pool wall, improve the physical properties of the surface, and reduce the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: clean up the calcium compound around the leaking crack of the concrete structure, for the crack of the small flow infiltration, adopt the stone cutting knife to cut out the process groove that the depth is 8mm and the width is 5mm along the crack, and the fast leak-stopping agent is used to seal the crack, Then configure polymer cement with a glue content of about 15%. The glue is made of acrylic emulsion and painted on the surface of the repaired cracks; Use a stone cutting knife to cut out a process groove with a width of 10mm and a depth of 10mm along the crack, pre-embed the grouting pipe for drainage, and seal the crack with a quick plugging agent, and then configure polymer cement with a glue content of 15%. Select acrylic emulsion, paint on the surface of the repaired cracks, and then use polyurethane grouting liquid for grouting repair, and pull out the grouting pipe after reaching the strength.

[0046] After the plugging is completed and the oute...

Embodiment 2

[0048] Embodiment 2: The plugging process The process is the same as that in Embodiment 1. After the plugging is completed and the outer surface of the concrete structure is cleaned, a concrete interface agent is used for primer treatment with a thickness of 0.5mm. Then prepare self-healing mortar, make mortar according to the proportioning of Table 1 embodiment 2, carry out uniform stirring, prolong 3 minutes than common mortar stirring time. Then paint according to the thickness of 15mm, and finish it at one time. Within three days, carry out water spray curing to maintain hydration reaction time and humidity.

[0049] After the self-healing mortar anti-seepage treatment is completed, the floating ash on the surface of the structure is removed, and the concrete interface agent is used as a primer with a thickness of 0.5mm. Prepare temperature difference compensation mortar: make mortar according to the ratio of Example 2 in Table 2, and stir evenly. The stirring time should...

Embodiment 3

[0050] Embodiment 3: The plugging process The process is the same as that in Embodiment 1. After the plugging is completed and the outer surface of the concrete structure is cleaned, a concrete interface agent is used for primer treatment with a thickness of 0.5mm. Prepare self-healing mortar then, make mortar by the proportioning of table 2 embodiment 3, carry out uniform stirring, prolong 3 minutes than common mortar stirring time. Then paint according to the thickness of 20mm, and finish it at one time. Within three days, carry out water spray curing to maintain hydration reaction time and humidity.

[0051] After the self-healing mortar anti-seepage treatment is completed, the floating ash on the surface of the structure is removed, and the concrete interface agent is used as a primer with a thickness of 0.5mm. Prepare temperature difference compensation mortar: make mortar according to the ratio of Example 3 in Table 2, and stir evenly. The stirring time should be 5 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com