Device and method for refluxing and drying wet aggregate in production process of dry-mixed mortar

A production process, dry-mixed mortar technology, used in progressive dryers, drying solid materials, drying, etc., can solve the problem that wet aggregate cannot be returned to the kiln for drying, and achieve the effect of reducing hidden dangers and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In view of the existing dry-mixed mortar products in the processing and production process, the process of drying the aggregates cannot guarantee the dryness of the aggregates, resulting in the mixing of wet aggregates into the production raw materials, which makes the dry-mixed mortar products prone to caking, The hardening phenomenon even affects the technical defect of product quality. The present invention proposes a process method of adding wet aggregate reflux drying in the aggregate drying process of dry-mixed mortar, so that the wet aggregate in the aggregate drying process can be effectively controlled. Appeared, improving the processing quality of dry-mixed mortar products.

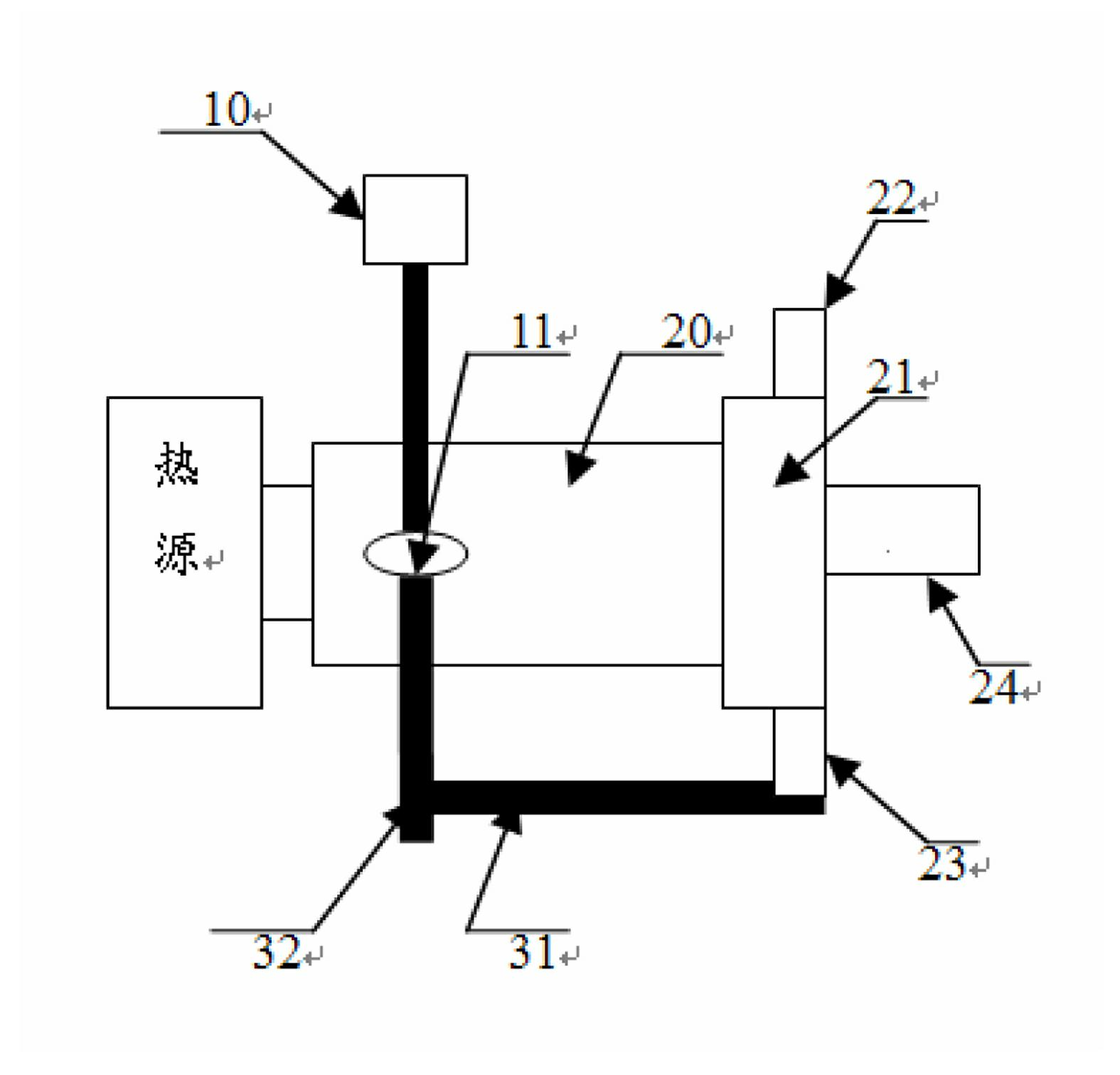

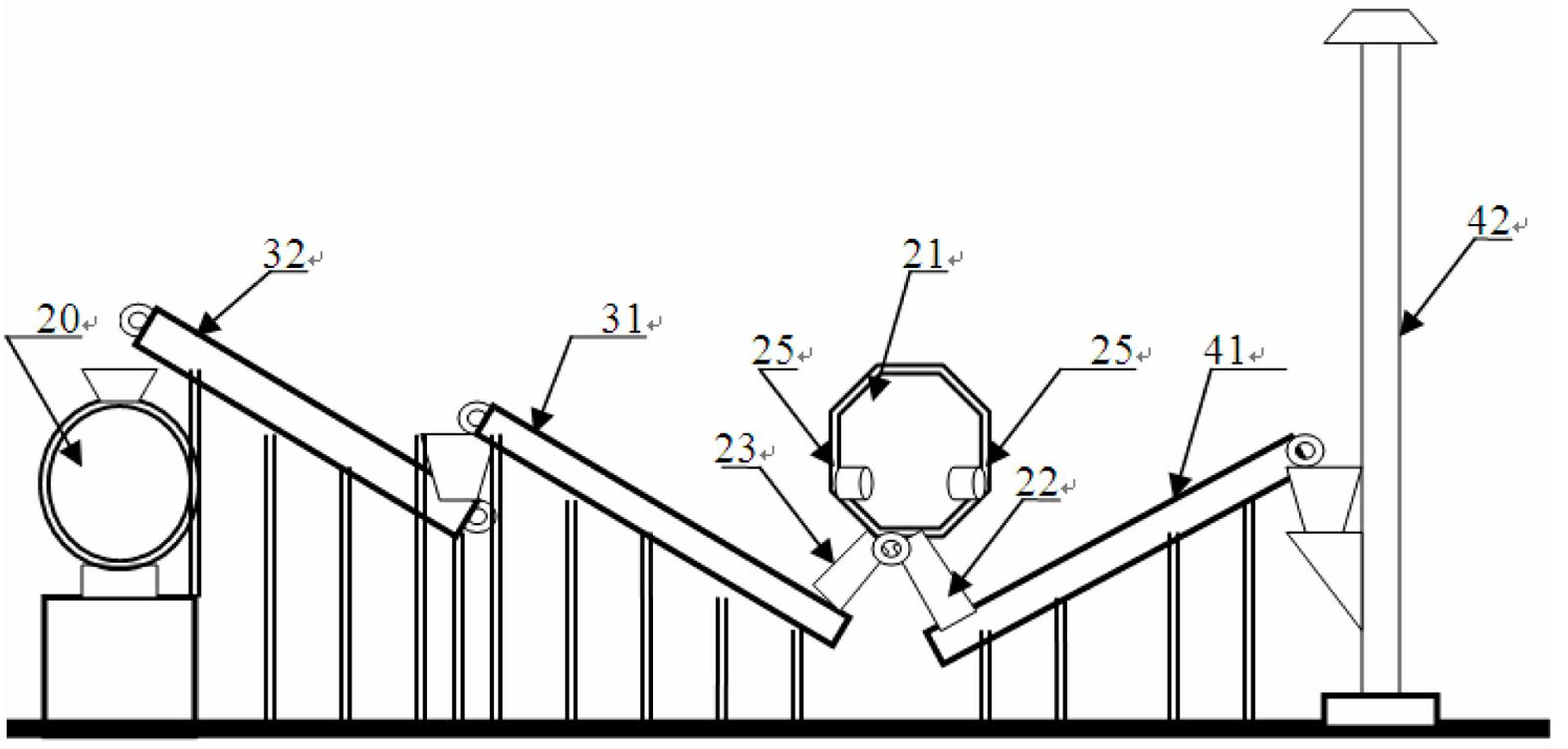

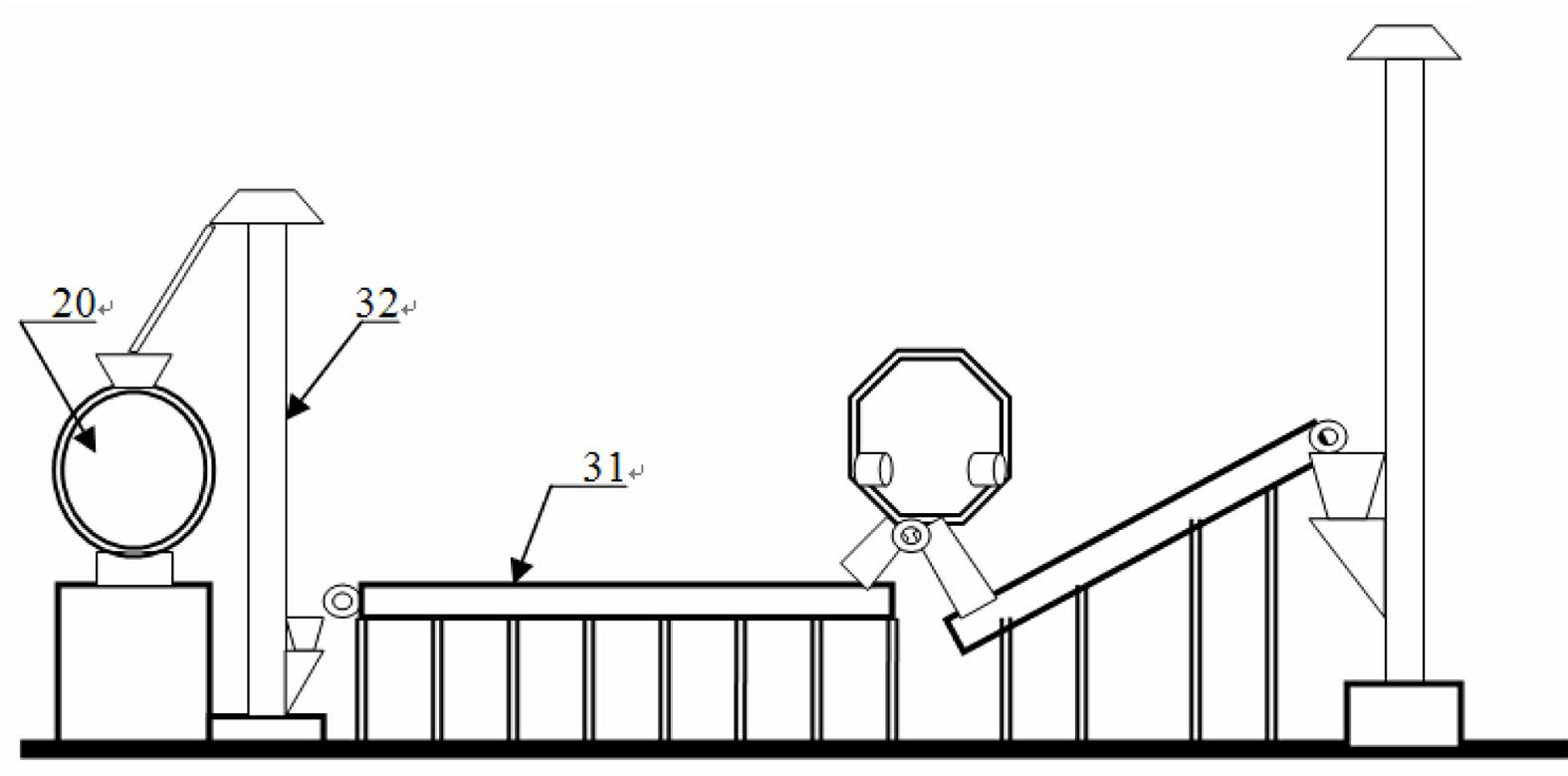

[0023] Such as figure 1 As shown, the reflux drying device proposed by the present invention is used in the aggregate drying process for reflux drying wet aggregate. The reflux drying device includes: a drying kiln 20 connected to a heat source (such as a hot blast stove) at one end, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com