Full-automatic non- backer pipe cutting machine tool and operation method thereof

A fully automatic, backing technology, used in pipe shearing devices, shearing devices, shearing machine equipment, etc., can solve the problems of severe wear of backing, severe wear of feeding chucks, and low dimensional accuracy of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

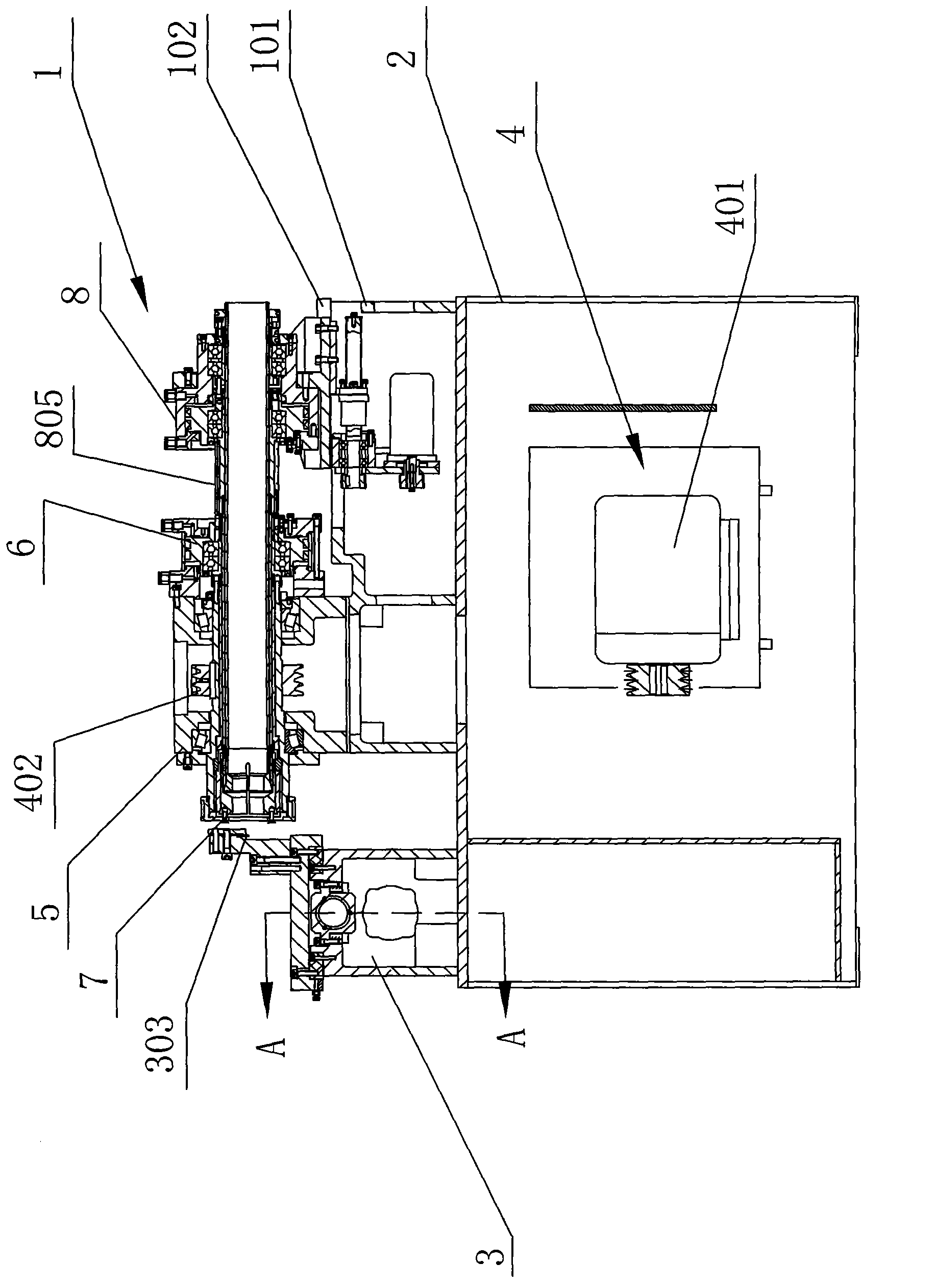

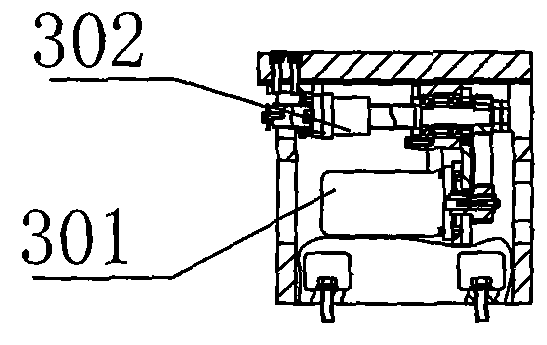

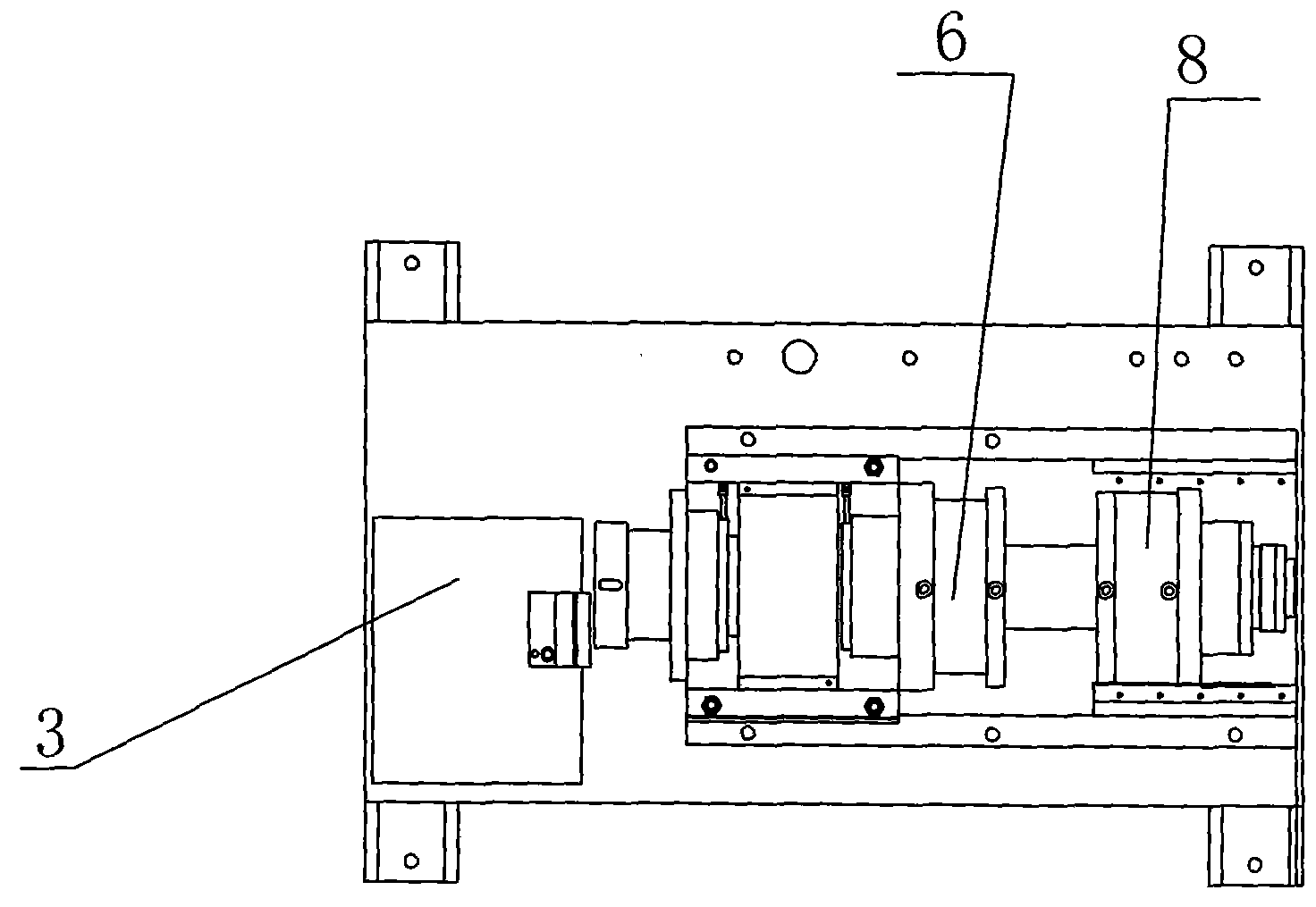

[0046] like Figure 1-1 to Figure 5-2 As shown, a fully automatic pipe cutting machine tool without backing is used for cutting tubular workpieces 20, and includes a main machine 1, a machine tool installation platform 2 and a tool box 3. The tool box 3 is arranged in front of the main engine 1, and the main engine 1 includes a lathe base 101, a drive motor assembly 4, a main shaft assembly 5, a front cylinder 6, and a front chuck clamping structure 7; the drive motor assembly 4 includes a drive motor 401 and a shaft pulley 402, the spindle assembly 5 includes a spindle box 501, a hollow spindle 502 and a cylindrical pin A503, and the front cylinder 6 includes a front cylinder body 601, a front cylinder piston 602, a front cylinder shaft 603, a front cylinder air pipe joint 604 and a front chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com