Impermeable concrete and preparation method thereof

A technology of impermeable concrete and waste rubber, which is applied in the field of concrete, can solve the problems of concrete strength reduction, etc., and achieve the effects of improving flexural strength, improving mechanical properties, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

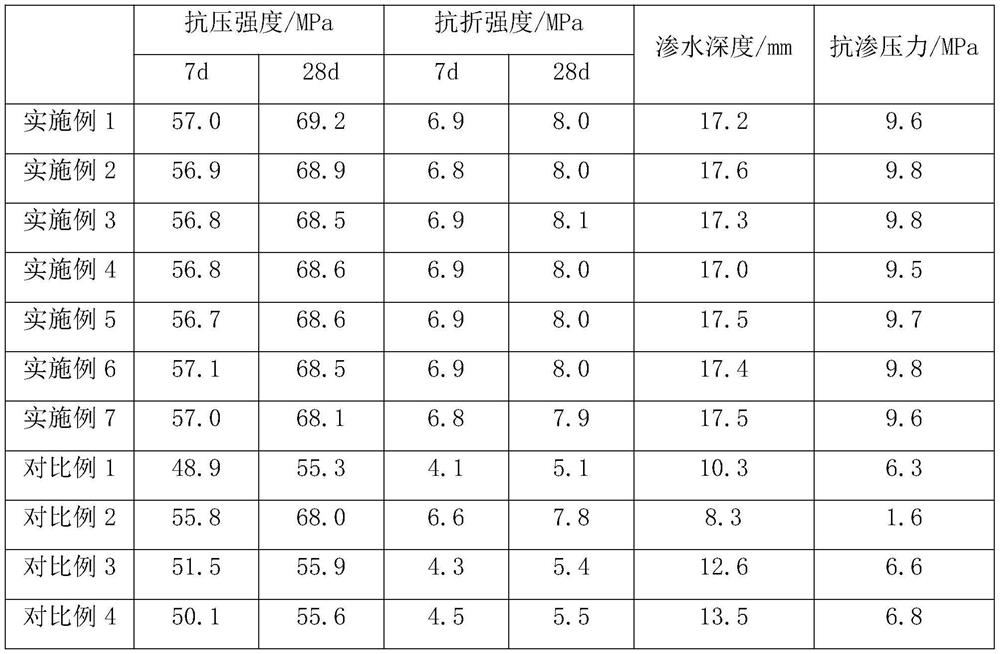

Examples

Embodiment 1

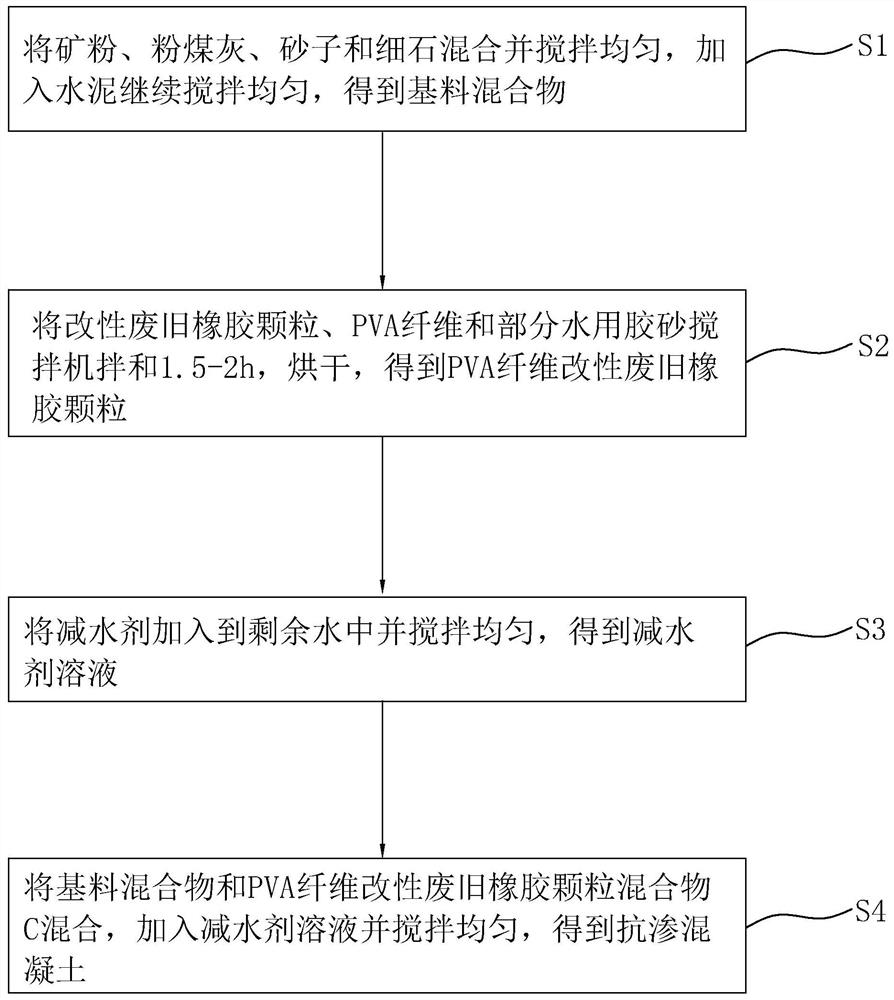

[0053] Embodiment 1: as figure 1 , a kind of impervious concrete, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0054] S1, mix mineral powder, fly ash, sand and fine stone and stir evenly, add cement and continue stirring evenly to obtain base material mixture;

[0055] S2, mix the modified waste rubber particles with the same weight of water, add PVA fibers with an average length of 6mm and an average diameter of 16mm, mix with a mortar mixer for 1.5h, and dry at 60°C for 4h to obtain PVA fiber modified waste rubber particles;

[0056] S3, adding the water reducer to the remaining water and stirring evenly to obtain a water reducer solution;

[0057] S4, mixing the base material mixture and the PVA fiber-modified waste rubber particle mixture C, adding a water reducer solution and stirring evenly to obtain impermeable concrete.

[0058] In this example, the preparation steps of modified waste rubber...

Embodiment 2-6

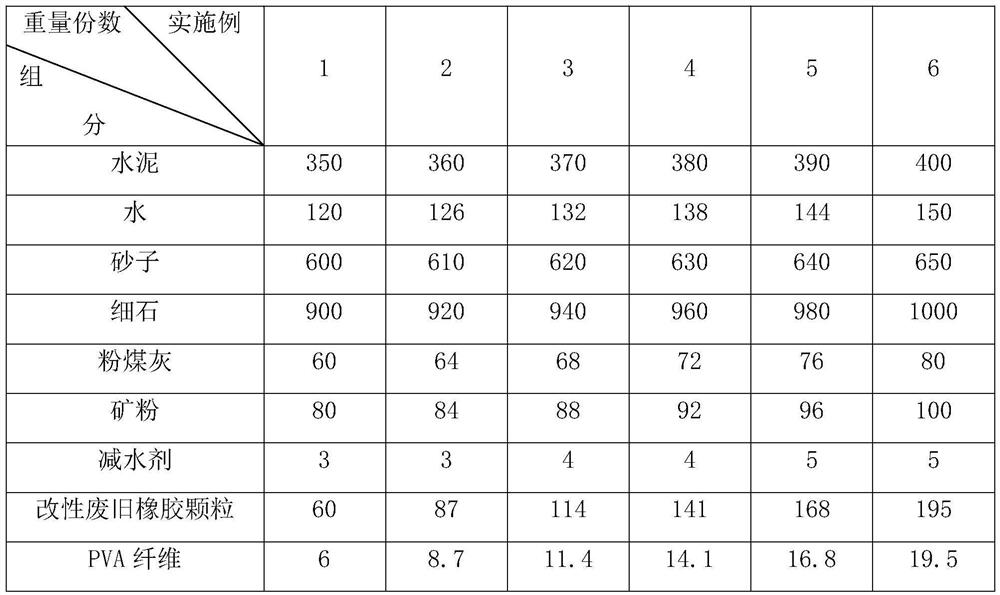

[0059] Example 2-6: An anti-seepage concrete, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0060] Each component and parts by weight thereof in table 1 embodiment 1-6

[0061]

Embodiment 7

[0062] Example 7: An impermeable concrete, the difference from Example 1 is that in this example, the preparation steps of modified waste rubber particles are: adding 1 part of waste rubber particles with a fineness of 18 mm to 4 parts Soak in 1mol / L NaOH solution for 3 hours, then wash the waste rubber particles with clean water to pH = 8.0, dry at 80°C, soak in 6 parts of absolute ethanol with 4 parts of silane coupling agent for 3 hours, wash with water Wash and dry at 80°C to obtain modified waste rubber particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com