GHB (Glazed Hollow Bead) heat preservation and heat insulation building wall body and construction technology

A technology of vitrified microbeads and thermal insulation, which is applied in thermal insulation, construction, building components, etc., to achieve the effects of improving crack resistance, overcoming high water absorption, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

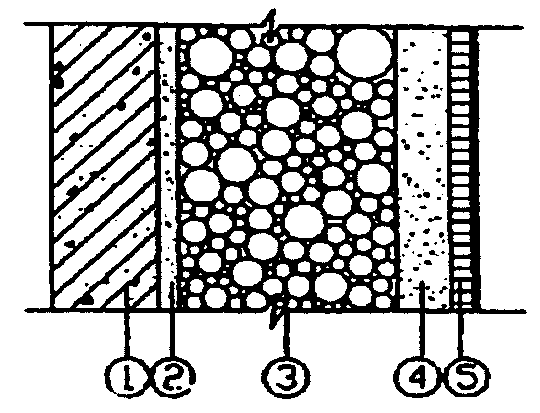

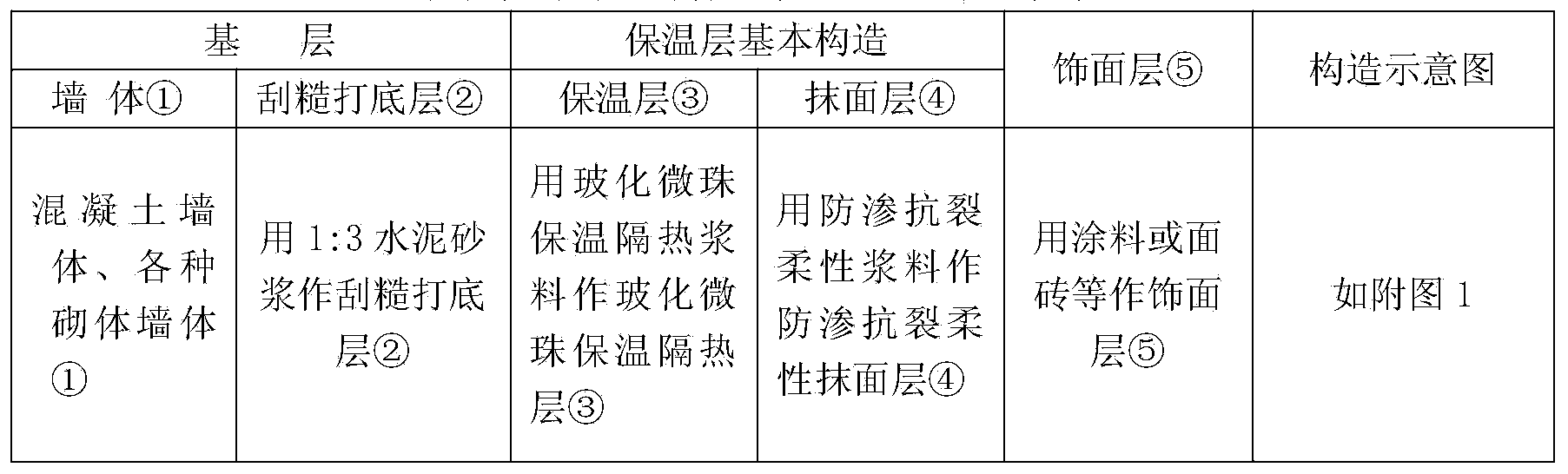

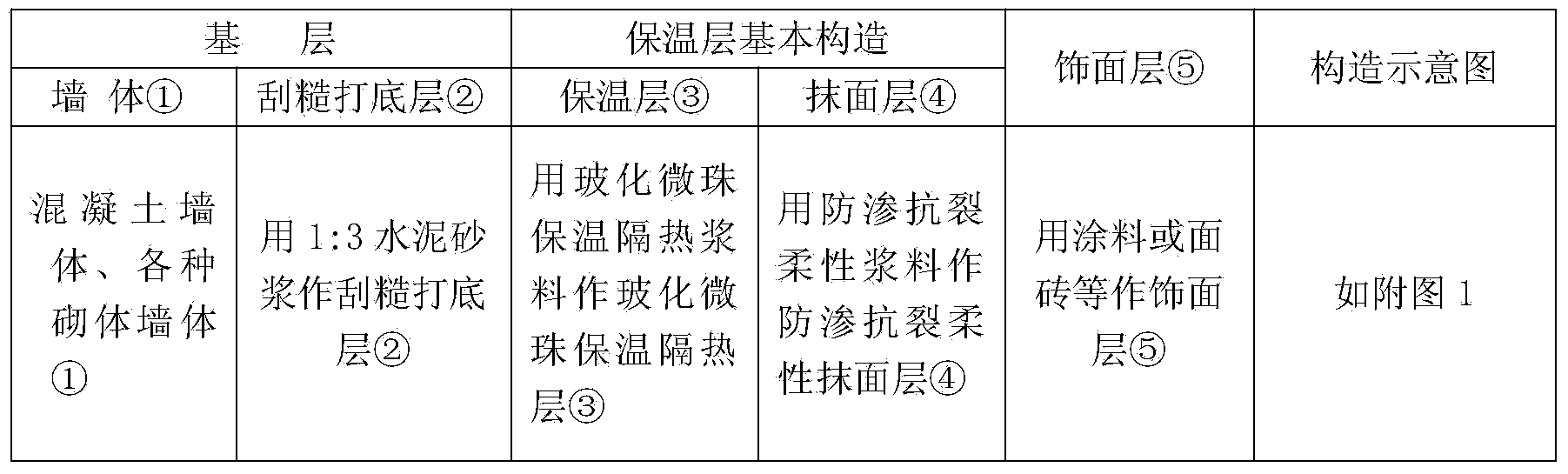

[0060] The present invention will be further described by using the accompanying drawings and examples.

[0061] The present invention is an invention patent product that adopts the thermal insulation material with good thermal insulation performance, anti-seepage and crack resistance, safety and fire prevention, and can realize energy saving and consumption reduction of the building structure - vitrified microbead thermal insulation material, which is used in the base layer of the building wall There are roughened bottom layer, vitrified microbead insulation layer, anti-seepage and crack-resistant flexible plastering layer, and finishing layer in sequence, forming a kind of vitrified microbead thermal insulation building wall, and a kind of vitrified microbead Construction technology for thermal insulation building walls; the vitrified microbead thermal insulation material includes vitrified microbead thermal insulation dry powder, anti-seepage and crack-resistant flexible mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com