Foamed ceramic heat preservation board

A technology of foamed ceramics and insulation boards, which is applied in the production and application of ceramic products and ceramic materials, and can solve the problems of iron tailings polluting the environment, narrow application range, and low strength of foamed ceramic materials, and meets the requirements of integration Good installation effect, good environmental protection performance, beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A foamed ceramic insulation board is composed of the following raw materials in parts by weight: 20 parts of coal gangue, 18 parts of iron tailings, 14 parts of fly ash, 5 parts of dolomite, 4 parts of silicon carbide, 5 parts of far-infrared ceramic powder, 4 parts of calcined talc, 8 parts of perlite, 3 parts of calcium carbonate, 10 parts of epoxy resin powder, 2 parts of anti-crack fiber, 1 part of brucite nanofiber, 7 parts of modified diatomite, and 2 parts of graphene.

[0024] The foamed ceramic insulation board of this embodiment is prepared by the following method:

[0025] (1) Add coal gangue and iron tailings to the atomization drying tower for cleaning and drying, then join the fly ash into the ball mill for ball milling, pass through a 60-mesh sieve, and take the product under the sieve as mixture A;

[0026] (2) After mixing dolomite, calcined talc, perlite, calcium carbonate, and modified diatomite, add them to a pulverizer for pulverization, pass throug...

Embodiment 2

[0031] A foamed ceramic insulation board is composed of the following raw materials in parts by weight: 25 parts of coal gangue, 10 parts of iron tailings, 22 parts of fly ash, 7 parts of dolomite, 5 parts of silicon carbide, 8 parts of far-infrared ceramic powder, 5 parts of calcined talc, 9 parts of perlite, 4 parts of calcium carbonate, 20 parts of epoxy resin powder, 4 parts of anti-crack fiber, 1 part of brucite nanofiber, 13 parts of modified diatomite, and 2 parts of graphene.

[0032] The foamed ceramic insulation board of this embodiment is prepared by the following method:

[0033] (1) Add coal gangue and iron tailings to the atomization drying tower for cleaning and drying, then join the fly ash into the ball mill for ball milling, pass through a 60-mesh sieve, and take the product under the sieve as mixture A;

[0034] (2) After mixing dolomite, calcined talc, perlite, calcium carbonate, and modified diatomite, add them to a pulverizer for pulverization, pass throu...

Embodiment 3

[0039] A foamed ceramic insulation board is composed of the following raw materials in parts by weight: 30 parts of coal gangue, 15 parts of iron tailings, 20 parts of fly ash, 10 parts of dolomite, 7 parts of silicon carbide, 6 parts of far-infrared ceramic powder, 7 parts of calcined talc, 10 parts of perlite, 6 parts of calcium carbonate, 15 parts of epoxy resin powder, 3 parts of crack-resistant fiber, 2 parts of brucite nanofiber, 11 parts of modified diatomite, and 3 parts of graphene.

[0040] The foamed ceramic insulation board of this embodiment is prepared by the following method:

[0041] (1) Add coal gangue and iron tailings to the atomization drying tower for cleaning and drying, then join the fly ash into the ball mill for ball milling, pass through a 60-mesh sieve, and take the product under the sieve as mixture A;

[0042] (2) After mixing dolomite, calcined talc, perlite, calcium carbonate, and modified diatomite, add them to a pulverizer for pulverization, pa...

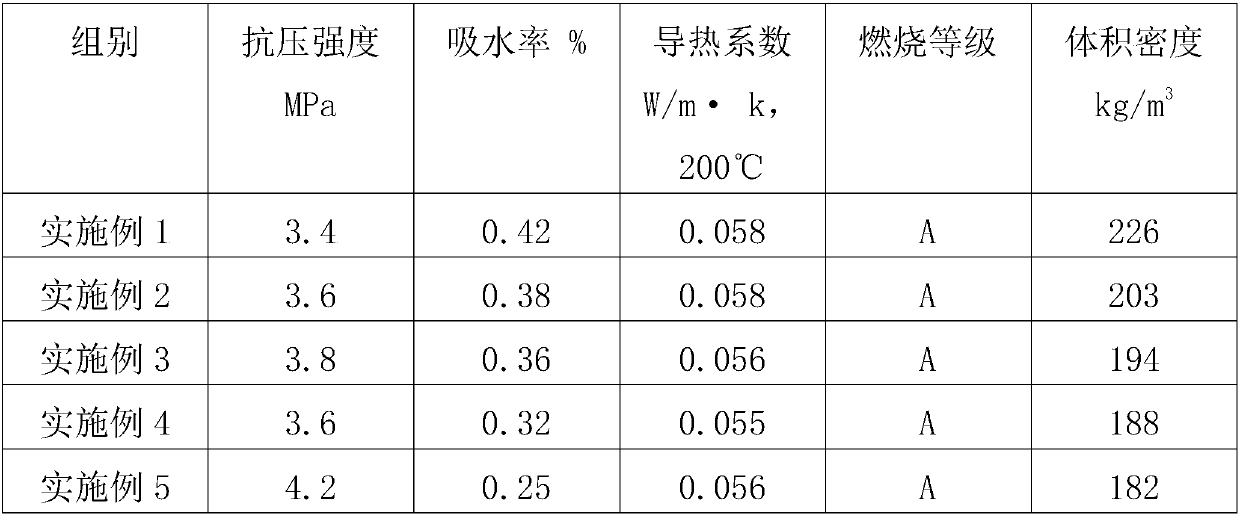

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com