Composite Metal Insulation Vacuum Panel

A composite metal and vacuum board technology, applied in the direction of heat preservation, building components, fire prevention, etc., can solve the problems of low puncture resistance, poor heat insulation and fire resistance, poor air tightness of vacuum bags, etc., and achieves superior air tightness and thermal insulation. Good fire resistance and good compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

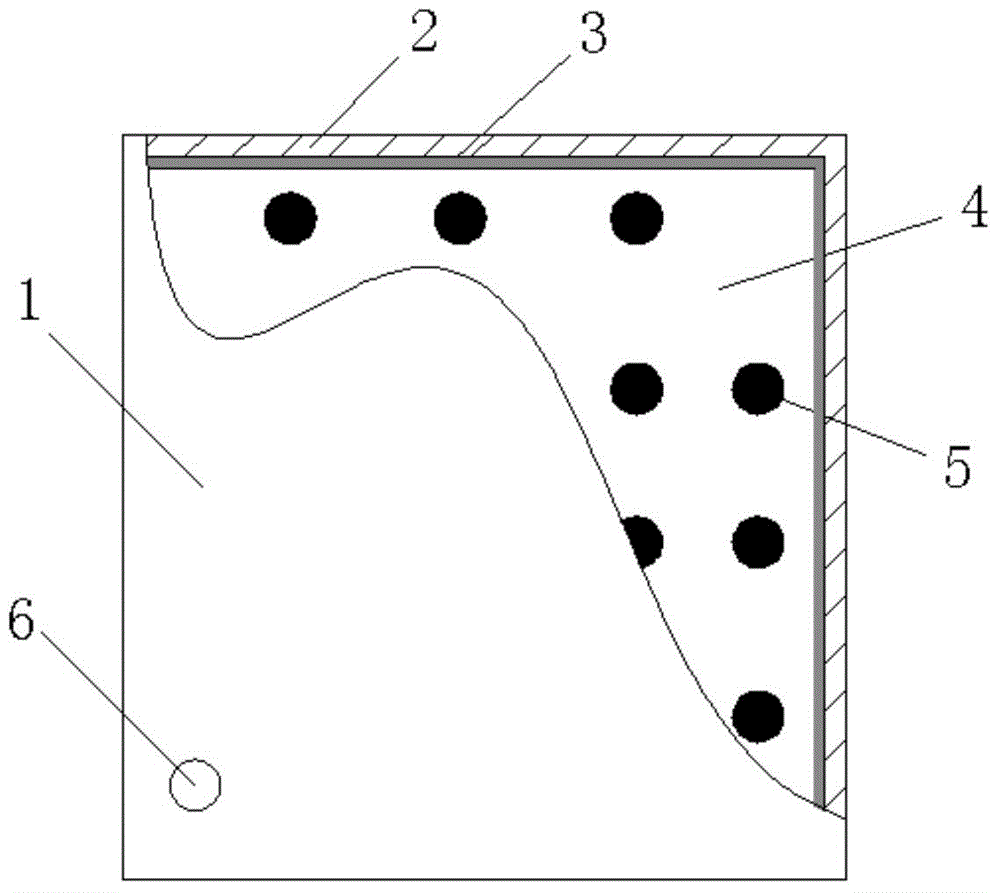

[0015] like figure 1 As shown, the vacuum panel involved in the present invention includes a panel 1, a connecting panel 2, a sealing layer 3 and a vacuum chamber 4; both the panel 1 and the connecting panel 2 are made of metal, and the connecting panel 2 connects the two panels 1 Together, the sealing layer 3 is arranged in the connecting plate 2, a vacuum cavity 4 is formed in the two panels 1, and a support 5 welded between the two panels 1 is also arranged in the vacuum cavity 4 , The vacuum chamber 4 is a low-radiation chamber, and there may be a getter in the vacuum chamber 4 , and an air extraction hole 6 is also arranged on the panel 1 .

[0016] The vacuum panel proposed in this embodiment not only has good compression resistance and impact resistance, but also has excellent airtight performance and good heat insulation and fire prevention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com