Extruded board door

A technology of extruded plastic board and door core, which is applied in the direction of door leaves, windows/doors, building components, etc., can solve the problems of wooden door deformation, bubbling, and cracking, and achieve good compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

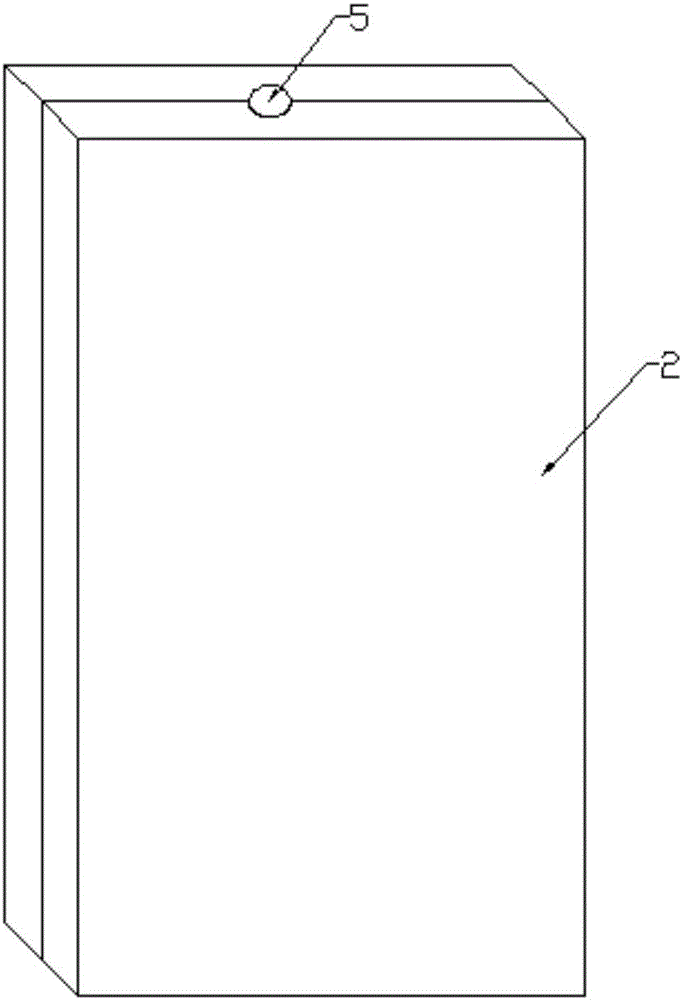

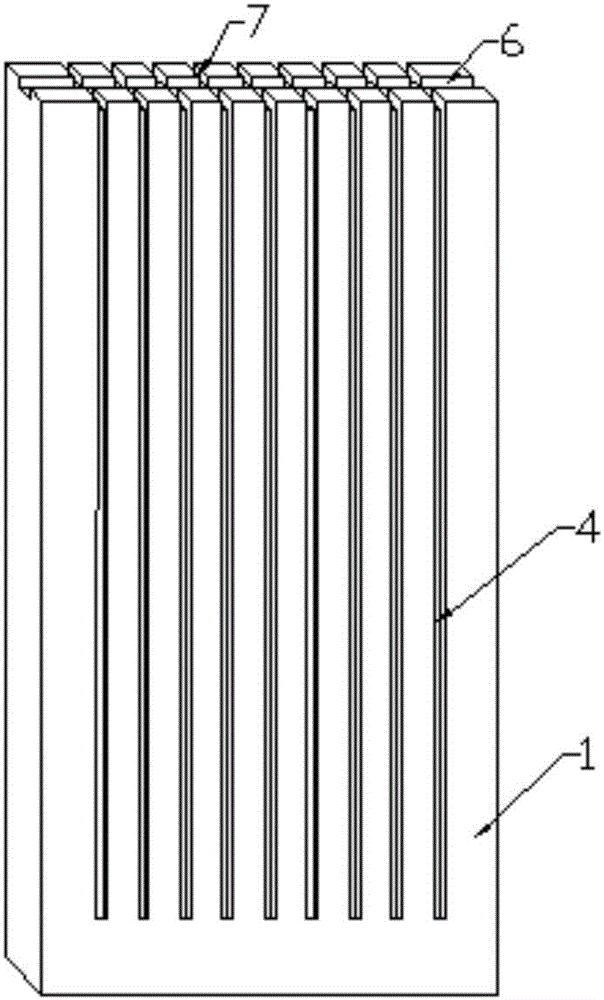

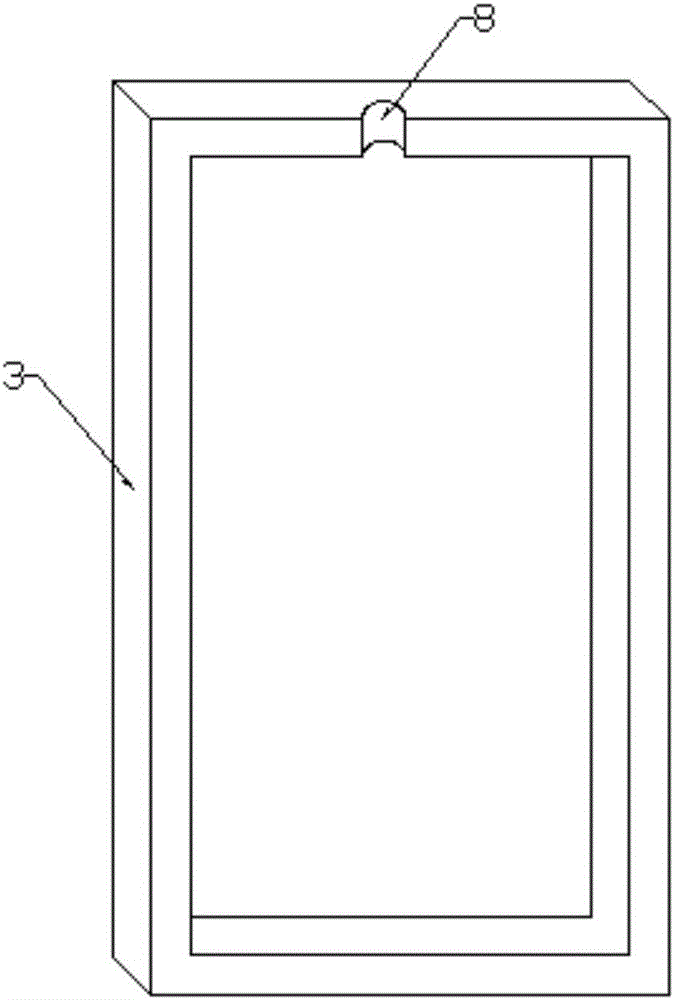

[0018] See attached figure 1 , 2 and 3, an extruded board door, comprising a door core 1 and a door cover 2, the door cover 2 is composed of two door panels 3, wherein the shape of the door core 1 is the same as that of the door panels 3, and the door core 1 It is fixed between two door panels 3, wherein the door core 1 is an integrally formed solid body, and the opposite sides of the door core 1 parallel to the door panels 3 are provided with several vertical grooves 4, and the short side of the door pocket 2 is A through hole 5 is provided on the side, and a transverse groove 6 is arranged in the middle of the top surface of the door core 1, and the opening direction of the transverse groove 6 is from one side of the long side of the door core 1 to the other side of the long side, wherein Each vertical groove 4 is provided with a channel groove 7 connected with the transverse groove 6 on the top surface of the door core 1 , and the through hole 5 is arranged on the transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com