A flame retardant composite fireproof cable

A fire-resistant cable and flame-retardant composite technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of limited manufacturing length, inconvenient installation and construction, expensive manufacturing equipment, etc., achieve long service life, reduce intermediate joints, and prevent fire The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

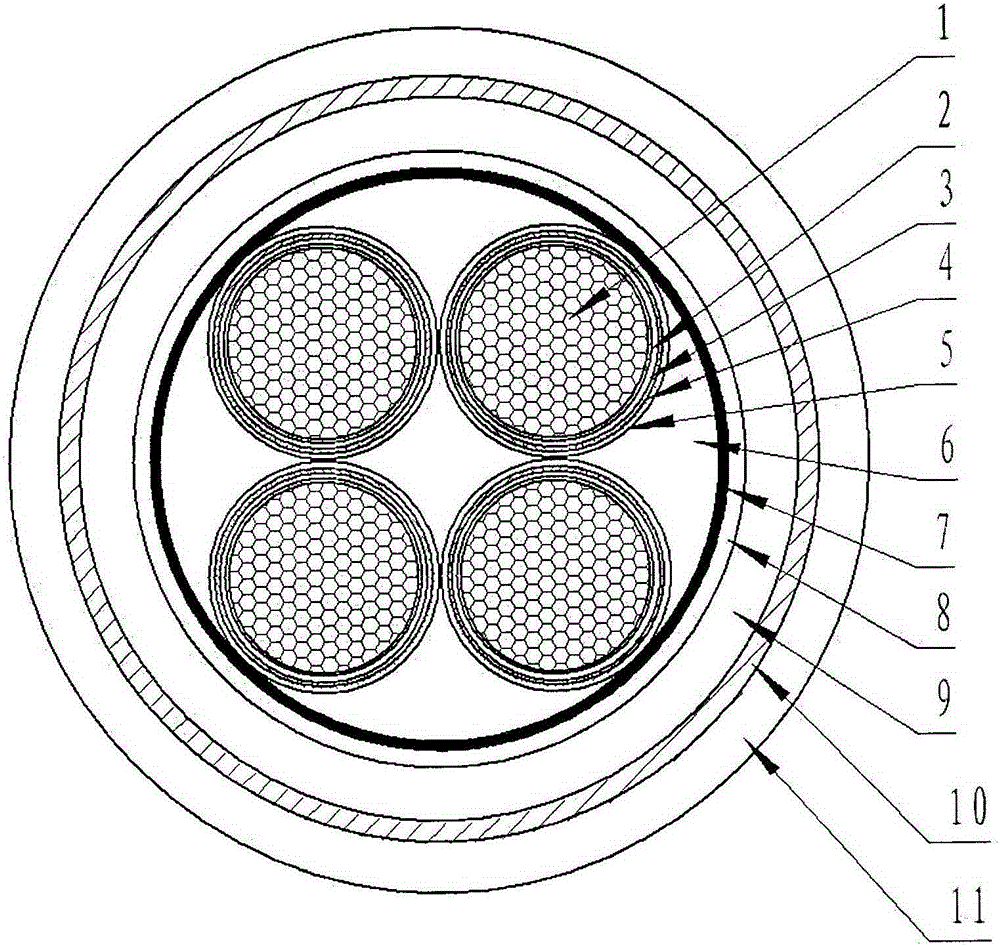

[0019] Such as figure 1 As shown, the flame-retardant composite fireproof cable of the present invention includes at least two stranded wires wrapped with a mica fireproof layer 2, an insulating moisture-proof layer 3, an aluminum alloy interlocking armor barrier layer 4, and a flame-retardant layer 5 from the inside to the outside. The cable core composed of copper wire conductor 1 is wrapped in the cable core tape 7, polyolefin oxygen barrier layer 8, ceramic fireproof layer 9, interlocking armor layer 10, and flame-retardant outer sheath from the inside to the outside. layer 11, and the flame-retardant filler 6 filled between the cable core and the cable-forming tape 7.

[0020] More specifically: the stranded copper wire conductor 1 is a tightly pressed stranded copper wire, and the nominal cross section can be: 1.5mm 2 、2.5mm 2 、46mm 2 、10mm 2 、16mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com