Prolamin composition and preparation method thereof

A technology of gliadin and composition, which is applied in the direction of protein food processing, protein food ingredients, dairy products, etc., can solve the problems of non-suitability for non-dairy cream, poor spreadability, etc., and achieve good instant solubility, high whipping ratio, and convenient storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] 14. A preparation method of gliadin composition, said method comprising the steps of:

[0058] (1) Dissolving 50-95 parts by weight of prolamin and optionally 0-28 parts by weight of polyhydroxy compound in 375-712 parts by weight of 70v / v% ethanol solution to obtain the first feed solution, wherein, The ethanol solution is at 45~55°C;

[0059] (2) Dissolving optionally 0-150 parts by weight of dextrin and optionally 0-28 parts by weight of polyhydroxy compound in 987-1874 parts of water to obtain a second feed liquid;

[0060] (3) Add 250 to 475 parts by weight of 40v / v% ethanol solution into the first feed liquid of step (1), and stir to dissolve the solute again to obtain a primary reverse phase precipitate, wherein the ethanol The solution is at 45-55°C;

[0061] (4) Add the primary reverse phase eluate obtained in step (3) to the second feed liquid obtained in step (2) and stir at a reaction temperature of 0-25°C; remove insoluble substances to obtain a secondary...

Embodiment 1

[0092] (1) Raw material dissolution: 50 parts by weight of zein (α-gliadin, β-gliadin and γ-gliadin account for 97wt%, 2wt% and 0% of gliadin respectively) are completely dissolved in In 375 parts by weight of 70v / v% ethanol solution at 50°C, the pH was adjusted to 6 to obtain the first feed solution.

[0093] (2) 25 parts by weight of dextrin were completely dissolved in 987 parts by weight of water to obtain a second feed liquid.

[0094] (3) Primary reverse phase precipitation: 250 parts by weight of 40v / v% ethanol (50°C) was added to the first feed liquid obtained in step (1), and stirred rapidly, and stirred and kept at 50°C for 30min, A reversed-phase precipitate was obtained.

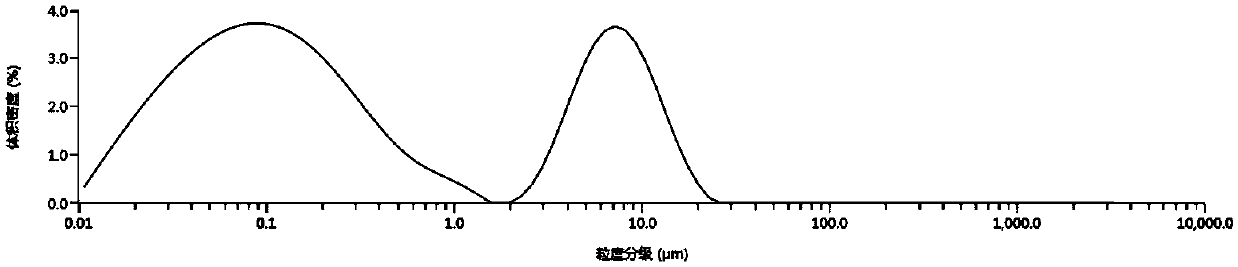

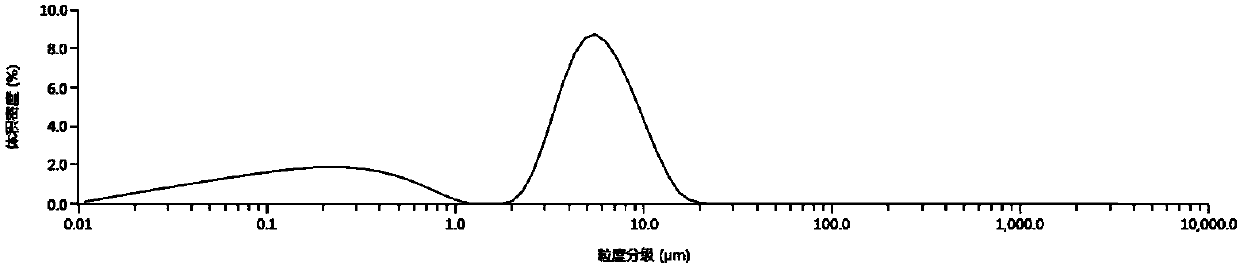

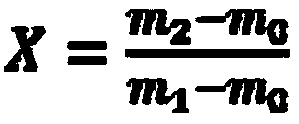

[0095] (4) Secondary reverse-phase precipitation: Add the primary reverse-phase precipitation in step (3) to the second material liquid obtained in step (2) and stir for rapid dispersion. The reaction temperature is controlled at 15°C, and the pore size is 100 μm. After the filter cloth removes...

Embodiment 2

[0099] (1) Dissolving raw materials: 60 parts by weight of zein (alpha-gliadin, beta-gliadin and gamma-gliadin respectively account for 90wt%, 5wt% and 1wt% of the prolamin), 7 wt% Parts of glycerol and 3 parts by weight of polyethylene glycol were completely dissolved in 450 parts by weight of 70v / v% ethanol solution at 45°C, and the pH was adjusted to 2.8 to obtain the first feed solution.

[0100] (2) 18 parts by weight of chitosan were completely dissolved in 1184 parts by weight of water to obtain a second feed liquid.

[0101] (3) One-time reverse phase precipitation: 300 parts by weight of 40v / v% ethanol (45°C) was added to the first feed liquid obtained in step (1), and stirred rapidly, and kept at 45°C for 30min to obtain A reverse phase eluate.

[0102] (4) Secondary reverse phase precipitation: Add the primary reverse phase precipitation solution in step (3) to the second material liquid obtained in step (2) and stir to make rapid dispersion. The reaction temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com