Method for controlling valve open and close using guiding valve

A technology of stop valve and pilot valve, which is applied in the direction of valve operation/release device, lift valve, valve details, etc., can solve the problems of short service life, high labor intensity, high production cost, etc., and achieve long service life, open and close Quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

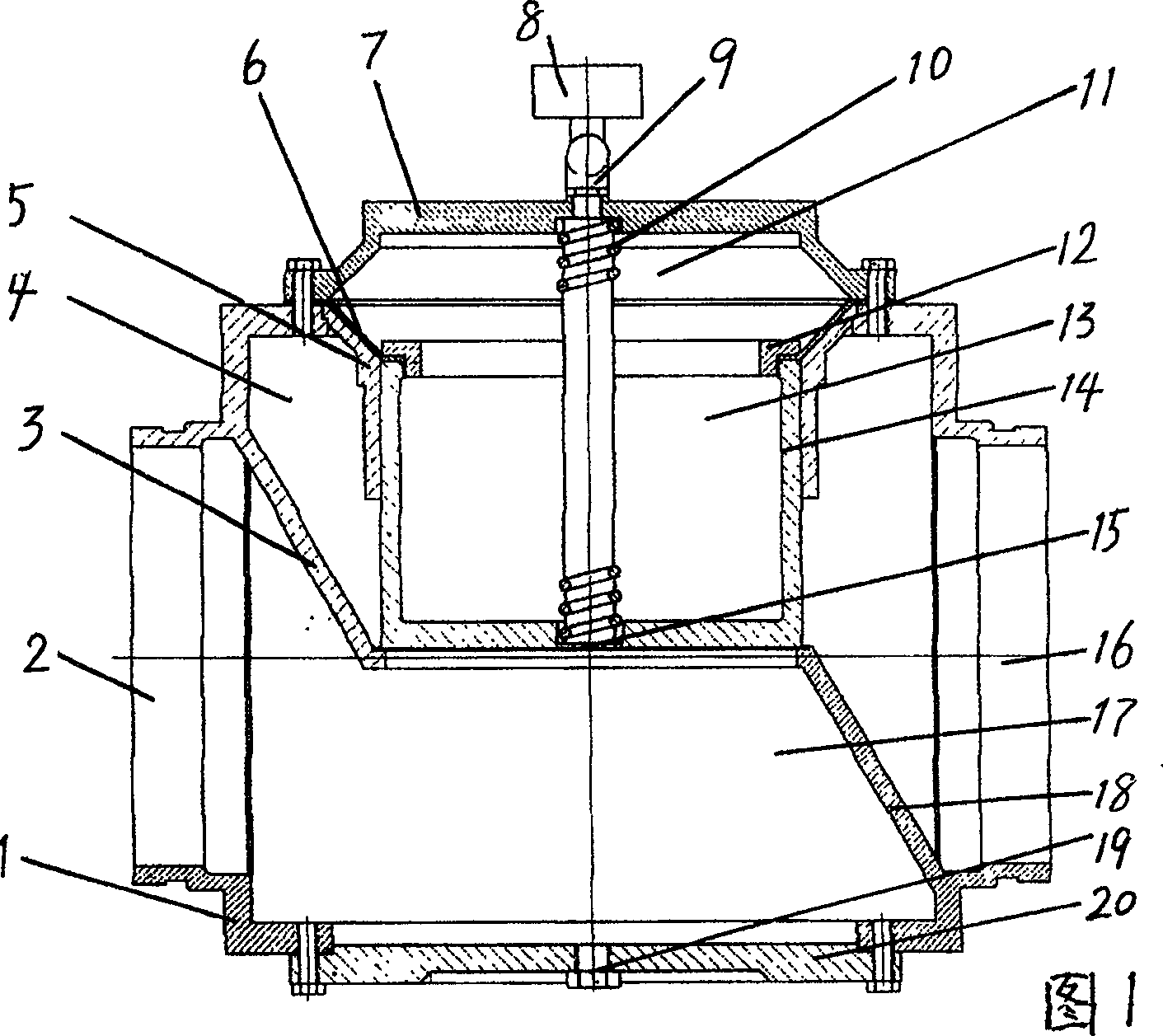

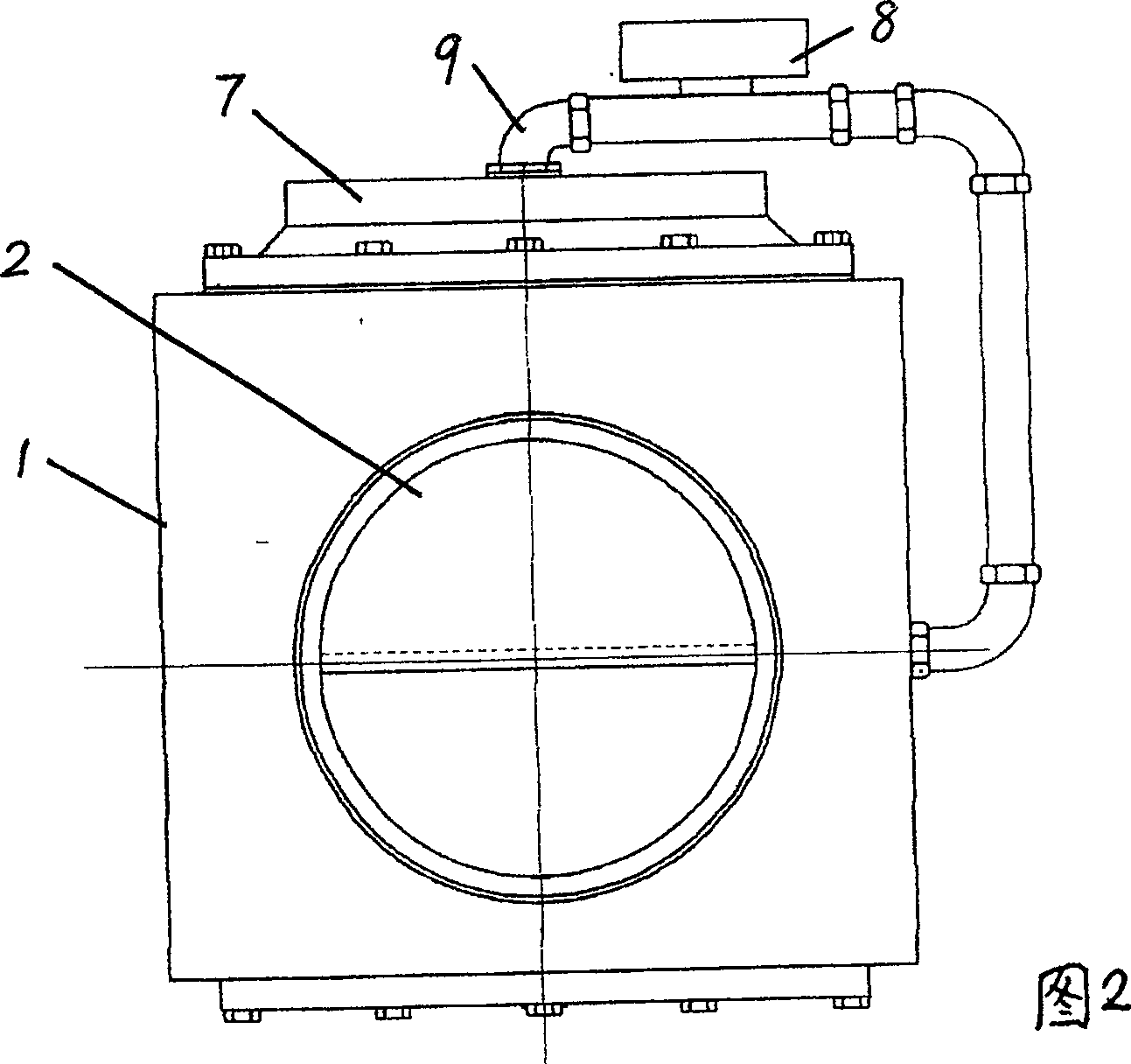

[0019] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings: the main valve body in the accompanying drawings is square, and the present invention is not limited by the shape of the valve body, which is beneficial to the transformation and reuse of the original circular valve body. Compared with the shut-off valve rotated by the mechanical hand wheel, the present invention has the following parts increase and decrease and structural improvement:

[0020] (1) The handwheel, valve stem and lifting nut are cancelled;

[0021] (2) Change the cake-shaped spool to be a container-shaped spool (14), and the bottom of the spool has a bottom hole (15); kind. The container-shaped spool is beneficial to contain the fluid in the valve body, and the fluid pressure balance in the upper and lower flow chambers can be adjusted by the self-weight of the fluid in the container.

[0022] (3) Add a guide sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com