Composite sponge, preparation method thereof, negative pressure drainage dressing, device and medical equipment

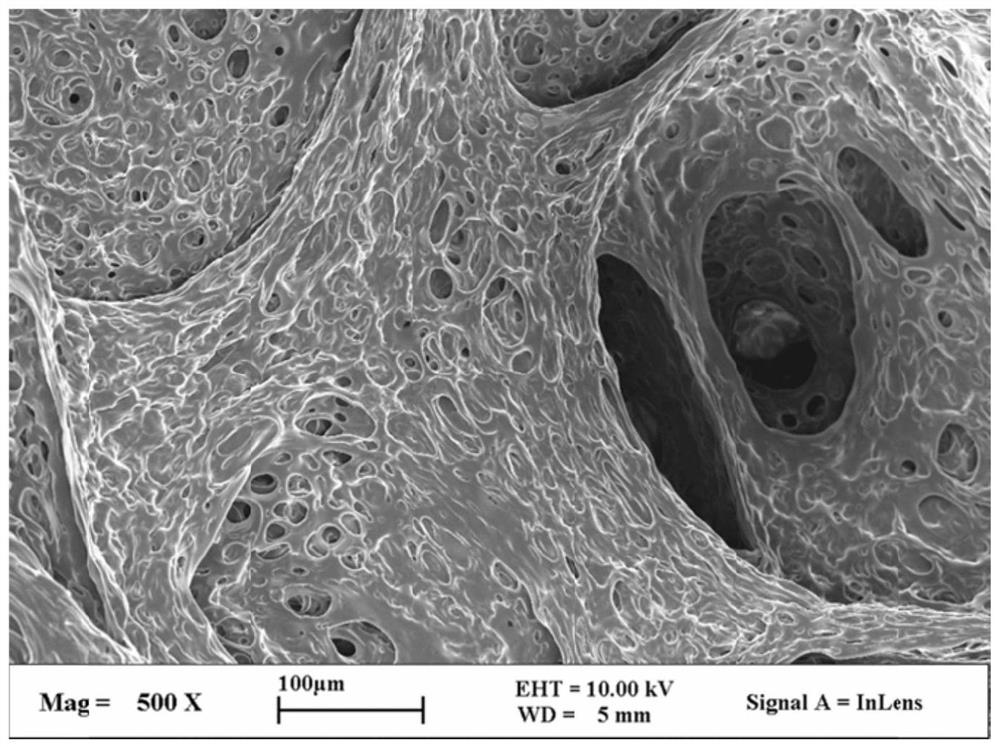

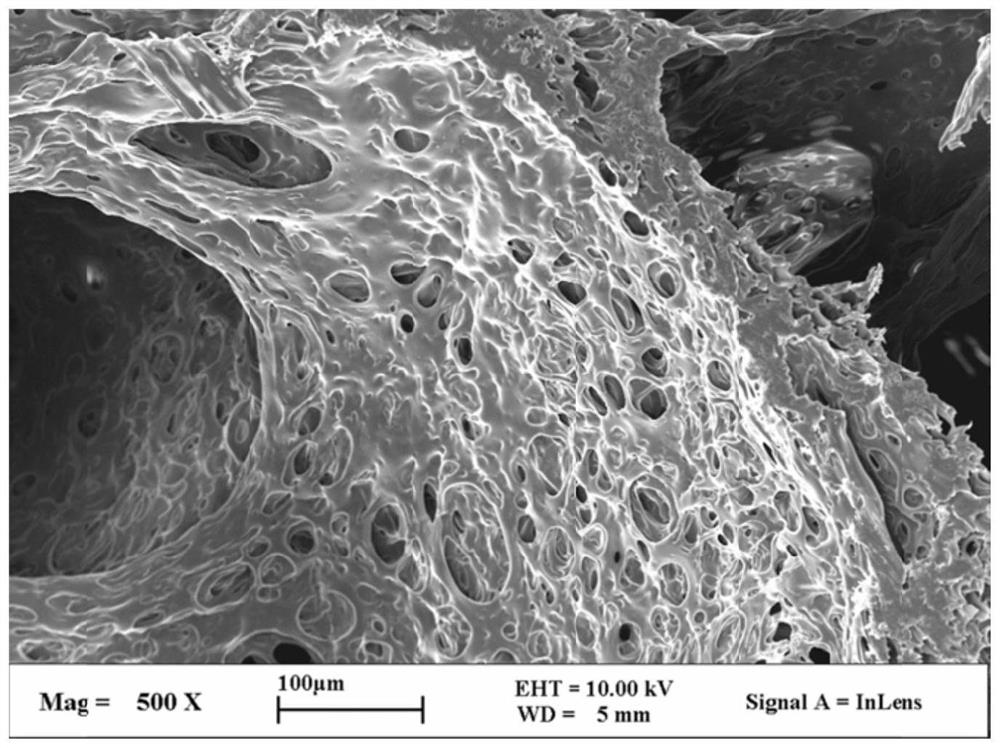

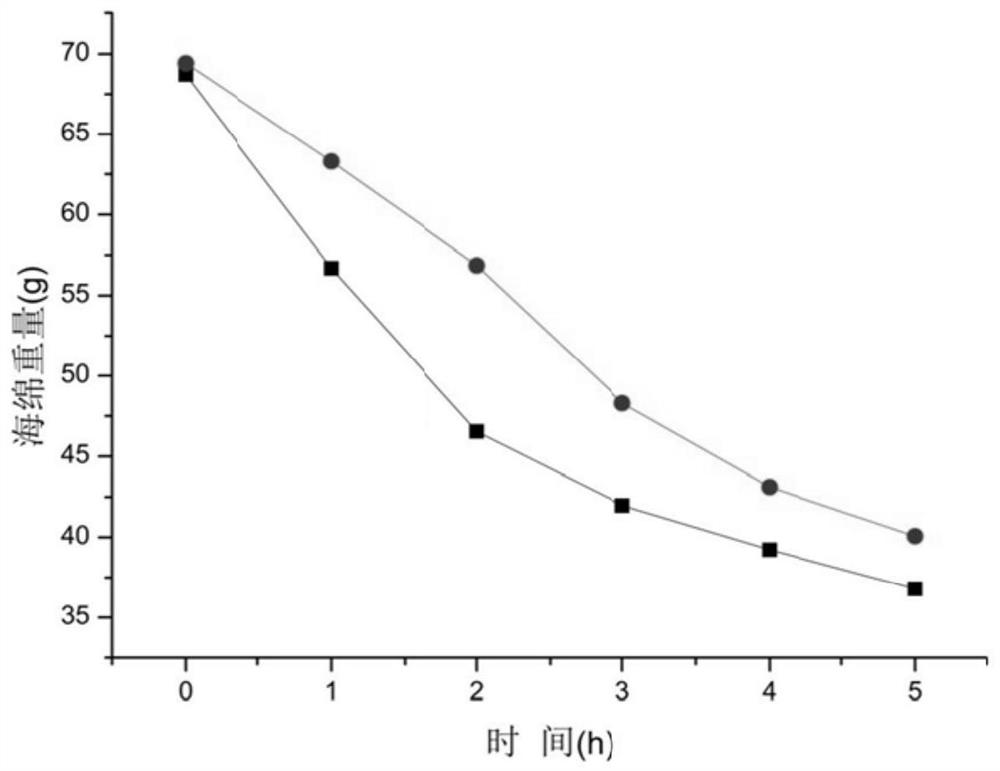

A composite sponge and raw material technology, applied in the field of biomedical materials, can solve the problems of inability to achieve water retention effect, water loss and hardening, etc., achieve excellent emulsification, change hardness, and improve water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A composite sponge, comprising the following components according to its mass fraction:

[0038]

[0039] The esterification degree of the above-mentioned propylene glycol alginate is 25%, the average molecular weight of the polyvinyl alcohol is 110000, and the alcoholysis degree is 85-99%.

[0040] The concrete preparation method of this composite sponge comprises the following steps:

[0041] Step 1: stirring and mixing propylene glycol alginate, polyvinyl alcohol and deionized water evenly, heating up to 90°C, and continuously stirring to dissolve all propylene glycol alginate and polyvinyl alcohol to obtain system A;

[0042] Step 2: add sodium bicarbonate and sodium lauryl sulfate to system A, stir for 30min, stirring speed is 1300rpm to prepare system B;

[0043] Step 3: Cool the system B to 50°C, add glyoxal, stir for 15 min, and stir at a speed of 1500 rpm to prepare system C;

[0044] Step 4: Cool the system C to 40°C, add hydrochloric acid, stir for 8 min...

Embodiment 2

[0047] A composite sponge comprises the following components according to its mass fraction:

[0048]

[0049] The concrete preparation method of this composite sponge comprises the following steps:

[0050] Step 1: Stir and mix propylene glycol alginate and an appropriate amount of deionized water evenly, heat up to 80°C to prepare a first solution, stir and mix polyvinyl alcohol and remaining deionized water evenly, heat up to 90°C to prepare a second solution, and continue Stir to make the first solution and the second solution mix uniformly to prepare system A;

[0051]Step 2: add sodium bicarbonate, calcium bicarbonate and sodium dodecylbenzene sulfonate to system A, stir for 15min, stirring speed is 1400rpm to prepare system B;

[0052] Step 3: Cool the system B to 50°C, add glutaraldehyde, stir for 20 min, and stir at a speed of 1600 rpm to prepare system C;

[0053] Step 4: Cooling system C to 40°C, adding sulfuric acid, stirring for 5 min, and stirring at a rate ...

Embodiment 3

[0056] A composite sponge, comprising the following components according to its mass fraction:

[0057]

[0058] The concrete preparation method of this composite sponge comprises the following steps:

[0059] Step 1: stirring and mixing the polyethylene glycol alginate, polyvinyl alcohol and deionized water evenly, heating the temperature to 90°C, and continuously stirring to dissolve all the polyethylene glycol alginate and the polyvinyl alcohol to obtain System A;

[0060] Step 2: Add ammonium bicarbonate and alkylphenol polyoxyethylene ether to system A, stir for 45 min, and stir at a speed of 1400 rpm to prepare system B;

[0061] Step 3: Cool the system B to 50°C, add formaldehyde, stir for 20 min, and stir at a speed of 1100 rpm to prepare system C;

[0062] Step 4: Cooling system C to 40°C, adding phosphoric acid, stirring for 15 min, and stirring at 1100 rpm to prepare system D;

[0063] Step 5: After stirring the system D evenly, pour it into the mold, conduct c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com