Polyamide composite reverse osmosis membrane with chlorine resistance and preparation method thereof

A technology of reverse osmosis membrane and polyamide, applied in the field of polyamide composite reverse osmosis membrane and its preparation, can solve problems such as poor resistance to active chlorine, achieve simple and easy preparation method, improve chlorine resistance, and simple and easy process row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

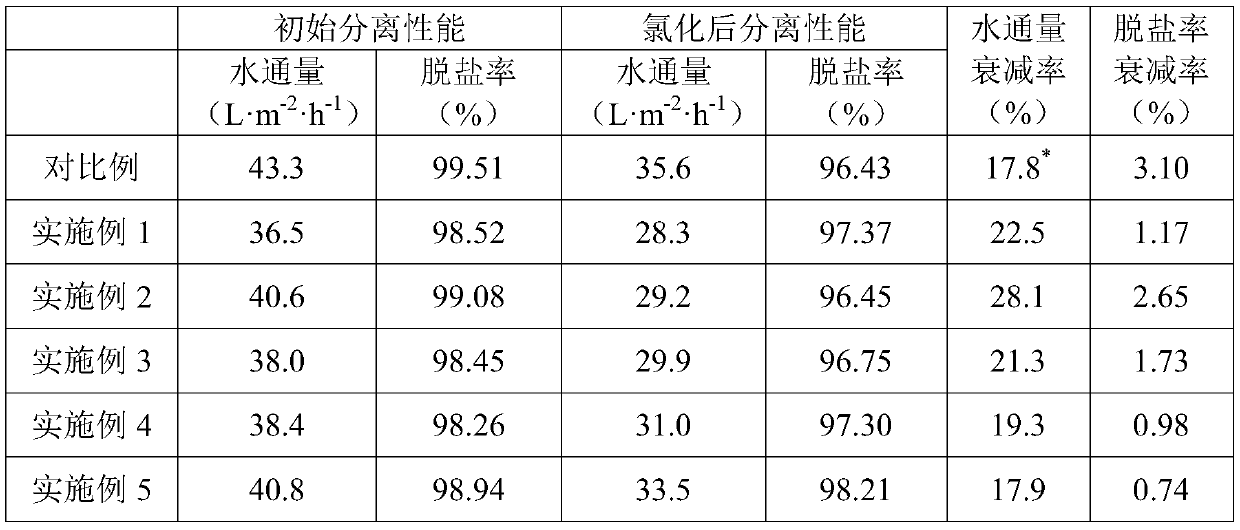

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a polyamide composite reverse osmosis membrane with chlorine resistance, comprising the following steps: (1) preparation of nascent polyamide composite reverse osmosis membrane; (2) pre-assembly of sulfur-containing sacrificial functional components (3) Modification of the surface of nascent polyamide composite reverse osmosis membrane with sulfur-containing sacrificial functional components.

[0046] In step (1), an aromatic polyamide separation layer is prepared on the porous ultrafiltration membrane support layer to obtain a nascent polyamide composite reverse osmosis membrane; in step (2), polyamine mediation units and sulfur-containing sacrificial unit to obtain sulfur-containing sacrificial functional components; in step (3), the sulfur-containing sacrificial functional components are loaded on the surface of the nascent polyamide composite reverse osmosis membrane by chemical bonding, and a chlorine-resist...

Embodiment 1

[0072] The polyamide composite reverse osmosis membrane with chlorine resistance in this example uses the nascent polyamide composite reverse osmosis membrane in the preparation process of the comparative example as the membrane to be modified. The preparation of sulfur-containing sacrificial functional components is as follows: 24mmol α-lipoic acid (LA), 30mmol N,N'-disuccinimidyl carbonate and 12mmol diisopropylethylamine were dissolved in 60mL acetone, under argon atmosphere The system was reacted overnight under protection, dark and normal temperature conditions; acetone was distilled off under reduced pressure, the residue was dissolved in dichloromethane, washed three times with pure water, and the organic phase was dried over anhydrous magnesium sulfate, filtered and concentrated to obtain the activated carboxyl group. Sulfur sacrificial unit LA * ; The sulfur-containing sacrificial unit LA after activation of 14 mmol carboxyl groups * , 14mmol ethylenediamine (EDA) an...

Embodiment 2

[0075] The polyamide composite reverse osmosis membrane with chlorine resistance in this example uses the nascent polyamide composite reverse osmosis membrane in the preparation process of the comparative example as the membrane to be modified. The preparation of sulfur-containing sacrificial functional components is as follows: 24mmol reduced glutathione (GSH), 48mmol N,N'-disuccinimidyl carbonate and 24mmol diisopropylethylamine were dissolved in 60mL acetone, The system was reacted overnight under the protection of argon, protected from light and at room temperature; the acetone was distilled off under reduced pressure, the residue was dissolved in dichloromethane, washed three times with pure water, the organic phase was dried with anhydrous magnesium sulfate, filtered and concentrated to obtain the activated carboxyl group Sulfur-containing sacrificial unit GSH * ; The sulfur-containing sacrificial unit GSH after activation of 14 mmol carboxyl groups * , 35mmol diethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com