Preparation method of conducting polymer/grapheme composite nanometer material

A conductive polymer and graphene composite technology, applied in nanotechnology, cable/conductor manufacturing, circuits, etc., can solve problems such as difficult control of polymer thickness, structural damage of conductive polymers, and difficulty in graphene film formation. Excellent chemical activity, controllable film thickness and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

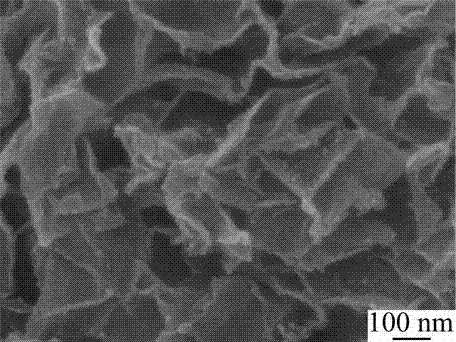

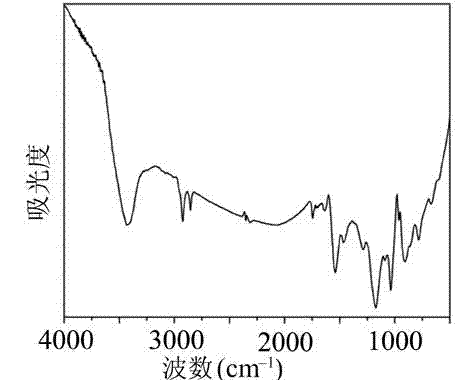

[0024] The preparation method of conductive polymer / graphene composite nanomaterial described in this embodiment specifically comprises the following steps:

[0025] (1) Disperse 50 mg of graphene obtained by chemically reducing graphite oxide into 10 ml of ferric chloride ethanol solution with a mass fraction of 5% and immerse it. Drying at ℃ to obtain ferric chloride-containing graphene.

[0026] (2) The ferric chloride-containing graphene and pyrrole monomer were placed in different positions in the polytetrafluoroethylene liner of the autoclave at a mass ratio of 5:1, and then reacted at 60°C for 12 h.

[0027] (3) After the above reaction product is centrifuged, washed and dried, the polypyrrole / graphene composite nanomaterial is obtained.

Embodiment 2

[0029] The preparation method of conductive polymer / graphene composite nanomaterial described in this embodiment specifically comprises the following steps:

[0030] (1) Disperse 50 mg of graphene obtained by reducing graphite oxide at high temperature and immerse it in 50 ml of 10% iron butanol p-toluenesulfonate solution. After a uniform oxide film is formed on the surface of graphene, centrifuge Then dry at 80° C. to obtain graphene containing iron p-toluenesulfonate.

[0031] (2) The obtained graphene containing iron p-toluenesulfonate and pyrrole monomer were placed in different positions in the polytetrafluoroethylene liner of the autoclave at a mass ratio of 2:1, and then reacted at 80 °C for 4 h.

[0032] (3) After the above reaction product is centrifuged, washed and dried, the polypyrrole / graphene composite nanomaterial is obtained.

Embodiment 3

[0034] The preparation method of conductive polymer / graphene composite nanomaterial described in this embodiment specifically comprises the following steps:

[0035] (1) Disperse 50 mg of graphene obtained by chemically reducing graphite oxide into 80 ml of ferric nitrate aqueous solution with a mass fraction of 15% and immerse it. Dry to obtain iron nitrate-containing graphene.

[0036] (2) The obtained graphene containing iron nitrate and pyrrole monomer were placed in different positions in the polytetrafluoroethylene liner of the autoclave at a mass ratio of 5:1, and then reacted at 50 °C for 24 h.

[0037] (3) After the above reaction product is centrifuged, washed and dried, the polypyrrole / graphene composite nanomaterial is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com