Preparation method of porous folded graphene with high specific surface area

A high specific surface area, graphene technology, applied in the chemical industry, can solve the problems of low specific surface area and loss of wrinkled structure of porous wrinkled graphene, and achieve the effect of facilitating ultrasonic atomization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

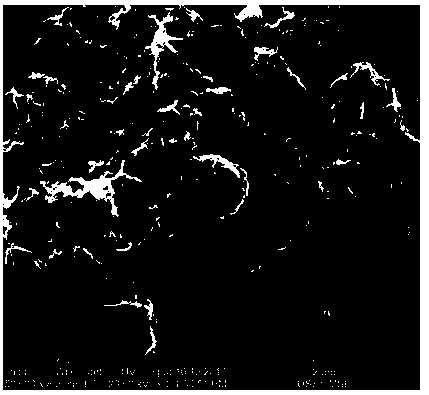

[0019] Take 400ml of 1mg / ml graphene oxide solution, first add 30ml of ammonia water with a concentration of 25% by mass, react at 30°C for 5h, then add sodium hydroxide, the mass ratio of sodium hydroxide to graphene oxide is 2:1, mix well , ultrasonic atomization treatment, the drying temperature is 500 ° C, the collected samples are heat-treated at 800 ° C for 1 hour under the protection of nitrogen, and washed until neutral. Finally, porous wrinkled graphene is obtained with a specific surface area of 1100m 2 / g. The morphology of porous and wrinkled graphene is as follows: figure 1 shown.

Embodiment 2

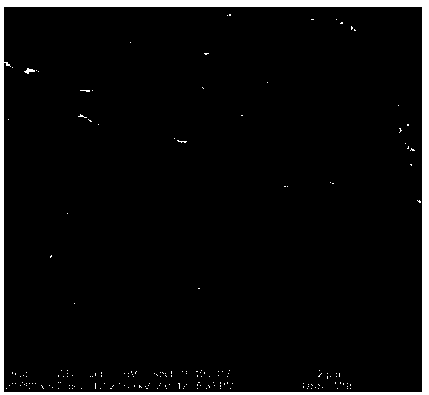

[0021] Take 200ml of 3mg / ml graphene oxide solution, first add 6g of anhydrous ethylenediamine, react at 80°C for 12h, then add potassium hydroxide, the mass ratio of potassium hydroxide to graphene oxide is 4:1, mix well, and ultrasonically Chemical treatment, the drying temperature is 300°C, and the collected samples are heat-treated at 700°C for 2 hours under the protection of nitrogen, and washed until neutral. Finally, porous wrinkled graphene is obtained with a specific surface area of 1636m 2 / g. The morphology of porous and wrinkled graphene is as follows: figure 2 shown.

Embodiment 3

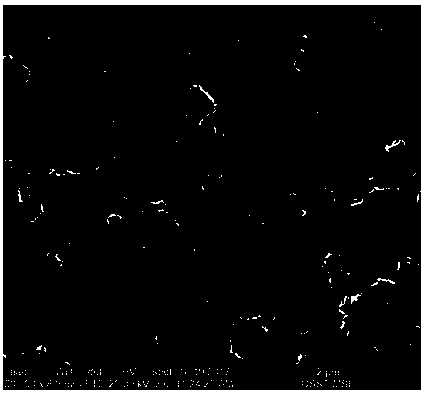

[0023] Take 300ml of 2mg / ml graphene oxide solution, first add 30g of tetraethylenepentamine, react at 100°C for 20h, then add potassium carbonate, the mass ratio of potassium carbonate to graphene oxide is 3:1, mix evenly, and conduct ultrasonic atomization treatment, The drying temperature is 600°C, and the collected samples are heat-treated at 1000°C for 2 hours under the protection of nitrogen, and washed until neutral. Finally, porous wrinkled graphene is obtained with a specific surface area of 1218m 2 / g. The morphology of porous and wrinkled graphene is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com