Concentrated solution of bubble liquid

A technology of concentrated liquid and bubble water, which is applied in the field of daily chemistry, can solve the problems of insufficient safety performance and poor bubble blowing performance, and achieve the effect of reasonable composition, excellent bubble blowing effect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

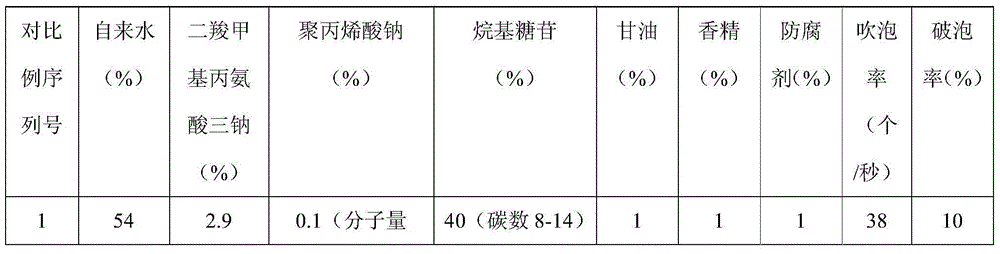

Examples

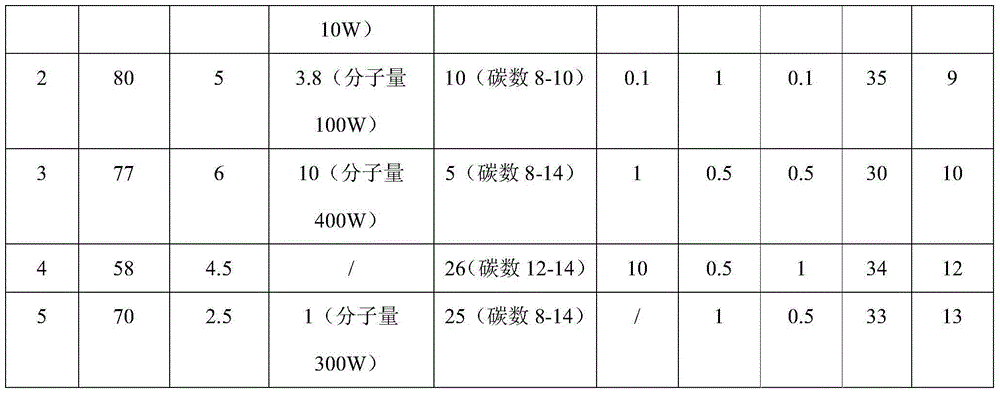

Embodiment 1

[0027] Take tap water 54% by mass percentage, trisodium dicarboxymethylalanine 2%, sodium polyacrylate (molecular weight 10W) 1%, alkyl glycoside (carbon number 8-14) (used alkyl glycoside is carbon number 8 Alkyl glycosides with -10 and alkyl glycosides with 12-14 carbons are compounded at a mass ratio of 7:3. The alkyl glycosides used are all products of Shanghai Fakai Chemical Co., Ltd., and the carbon number is 8- The batch of the alkyl glycoside of 10 is APG0810-13-39, and the batch of the alkyl glycoside of 12-14 is APG1214-13-79) 40%, glycerin 1%, flavor (orange) (purchased from Taizhou Jinxiang Food Additive Factory, Model: JX22123) 1%, Potassium Sorbate 1%, put the above raw materials into the stirring tank in turn and mix them uniformly to prepare the Bubble Water Concentrate 1.

[0028] Add the above-mentioned bubble water concentrate 1 to the water according to the mass percentage of 10%-20% to make the bubble water solution. The bubble blowing rate can reach ab...

Embodiment 2

[0031] Take 80% of tap water by mass percentage, 1% of trisodium dicarboxymethylalanine, 3.8% of sodium polyacrylate (molecular weight 100W), alkyl glycoside (8-10 carbon number) (the alkyl glycoside used is Shanghai Fakai The product of Chemical Co., Ltd., the batch is APG0810-13-39) 10%, glycerin 5%, essence (strawberry) (purchased from Taizhou Jinxiang Food Additive Factory, model: JX22067) 0.1%, sodium benzoate 0.1%, will The above-mentioned raw materials are sequentially added into the stirring tank and uniformly mixed to obtain the bubble water concentrate 2.

[0032] Add the above-mentioned bubble water concentrate 2 to the water according to the mass percentage of 10%-20% to make the bubble water solution. At room temperature, use the Haiyang Star automatic bubble machine model S998-14 to blow the bubbles. The bubble blowing rate can reach about 43 per second. Calculated by the number of bubbles after blowing for 5 seconds, the bubble breaking rate was 4%. The detect...

Embodiment 3

[0034] Take tap water 62% by mass percentage, trisodium dicarboxymethylalanine 6%, sodium polyacrylate (molecular weight 400W) 10%, alkyl glycoside (carbon number 8-14) (the carbon number used is 8 Alkyl glycosides with -10 and alkyl glycosides with 12-14 carbons are compounded at a mass ratio of 2:8. All alkyl glycosides used are products of Shanghai Fakai Chemical Co., Ltd., with a carbon number of 8- The batch of the alkyl glycoside of 10 is APG0810-13-39, and the batch of the alkyl glycoside of 12-14 is APG1214-13-79) 20%, glycerin 1%, flavor (orange) (purchased from Taizhou Jinxiang Food Additive Factory, Model: JX22123) 0.5%, Potassium Sorbate 0.5%, add the above-mentioned raw materials in a stirring tank in turn and mix them uniformly to prepare the Bubble Water Concentrate 3.

[0035] Add the above-mentioned bubble water concentrate 3 to the water according to the mass percentage of 10%-20% to make the bubble water solution. At room temperature, use the Haiyang Star au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com