Antimicrobial polyamide 6 fibre and production method thereof

An antibacterial polyamide and polyamide technology, which is applied in the directions of single-component polyamide rayon, chemical characteristics of fibers, botanical equipment and methods, etc., can solve the problem of the decline of fiber physical indicators, the rapid increase of the pressure of broken yarns and broken components , poor dispersion and other problems, to achieve the effect of improving the exchange rate of silver ions, omitting the drying process, and broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (a) Masterbatch preparation

[0033] Take 30 parts of silver-loaded composite inorganic antibacterial powder with an average particle size of 0.8μ, 22.5 parts of coupling agent TF-2, 1 part of antioxidant APG, and 1.6 parts of surfactant hard calcium acetate, and add them to the air-flow film mixer for drying. surface treatment method, the superfine material powder after surface treatment is mixed with 65 parts of polyamide 6 carrier in a high-speed mixer, and the obtained mixed powder is sent to a twin-screw extruder for blending and extrusion, and pelletized. The specific process is as follows:

[0034]

[0035] (b) Processing technology of antibacterial nylon 6DTY

[0036] Take 5 minutes of the above-mentioned antibacterial masterbatch and 95 parts of polycaprolactam for blending and spinning. The specific process is as follows:

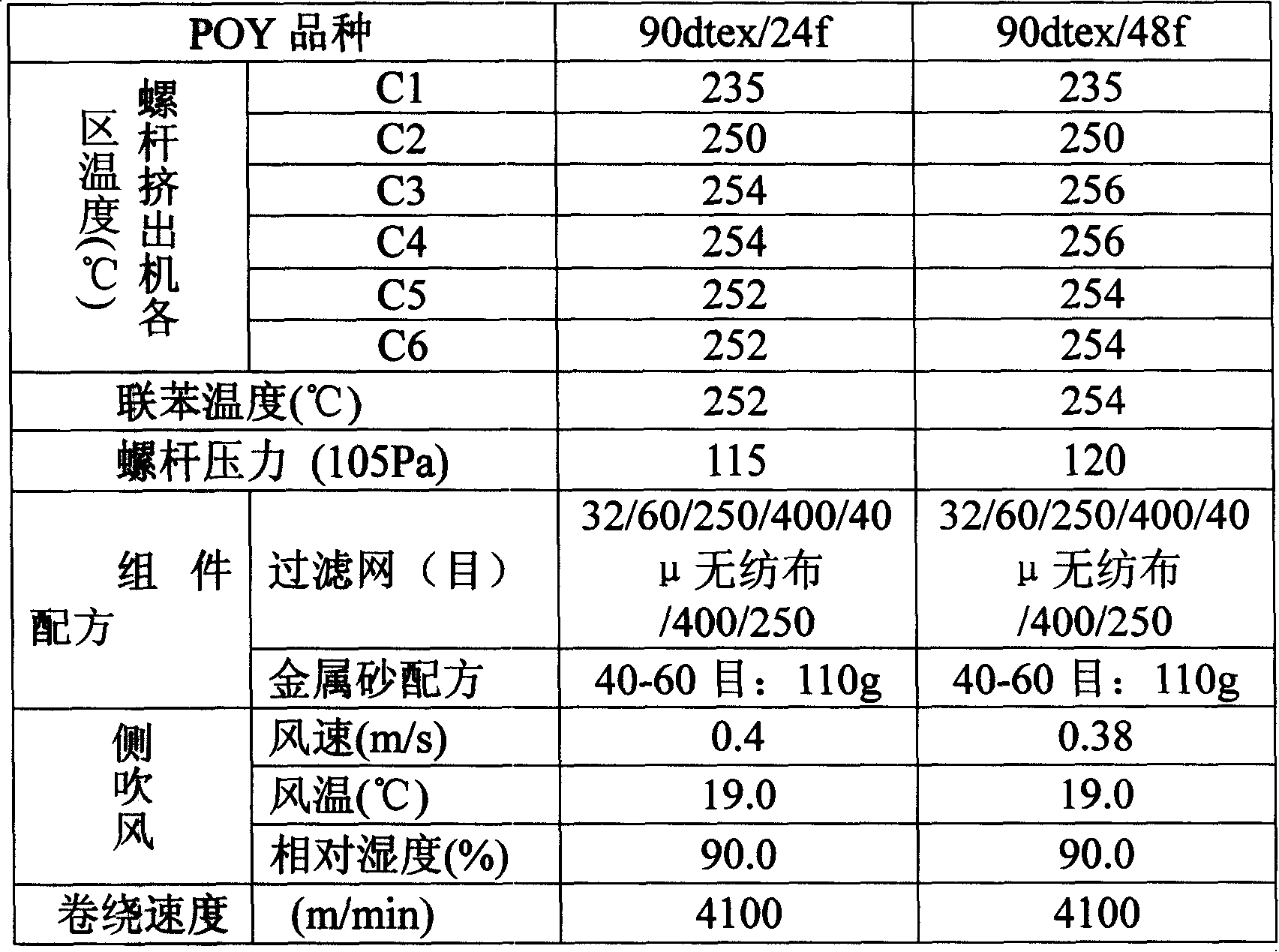

[0037] ①POY processing technology

[0038]

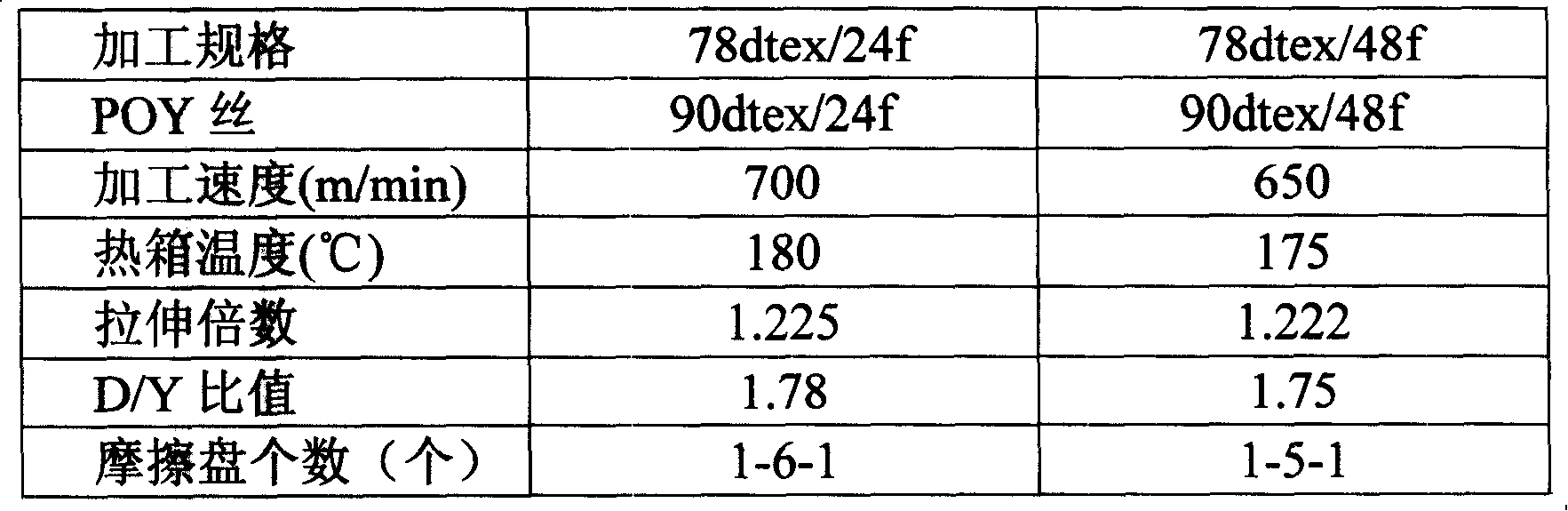

[0039] ②DTY processing technology

[0040]

Embodiment 2

[0042] (a) Masterbatch preparation

[0043] Take 20 parts of silver-loaded composite inorganic antibacterial powder with an average particle size of 0.4 μ, 22 parts of coupling agent TF-22 parts, 0.8 parts of antioxidant APG and 1.2 parts of surfactant hard calcium acetate, and add them to the air flow film mixer together. Dry surface treatment, the superfine material powder after surface treatment is mixed with 76 parts of polyamide 6 carrier in a high-speed mixer, and the obtained mixed powder is sent to a twin-screw extruder for blending and extrusion, and pelletized. The specific process is as follows:

[0044]

[0045] (b) Processing technology of antibacterial nylon 6HOY and FDY

[0046] Take 4 points of the above-mentioned antibacterial masterbatch, and 96 parts of polycaprolactam are blended and spun, and the specific process is as follows:

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com