Gypsum-based light plastering material and preparation method thereof

A gypsum-based, lightweight technology, applied in the construction field, can solve the problems of low-strength and rich-colored wallpaper bases, dust and construction waste, waste of manpower and time, etc., to eliminate hollow walls, improve construction, and increase The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

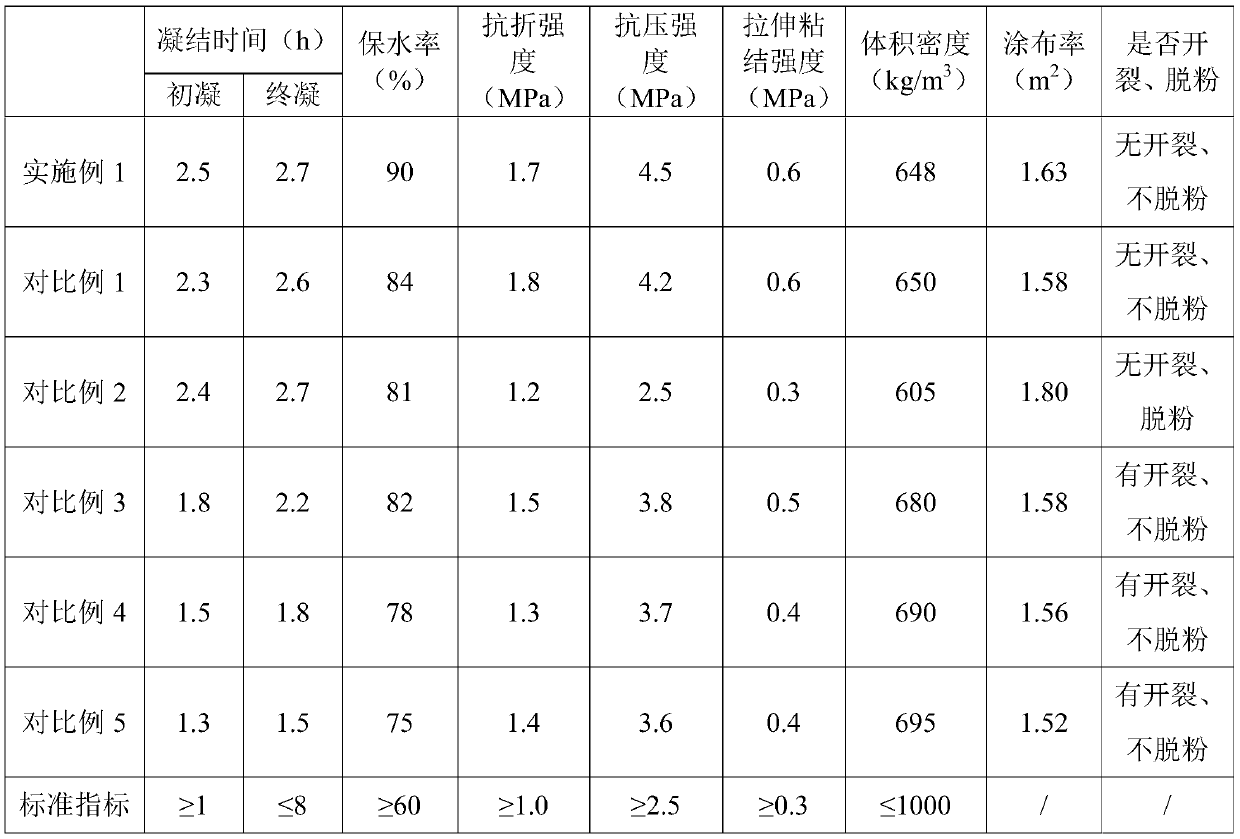

Examples

preparation example Construction

[0052] The second aspect of the present invention provides a method for preparing a gypsum-based lightweight plastering material, which at least includes the following steps: adding each component into a mixer and mixing well and uniformly.

[0053] In a preferred embodiment, the preparation method of the gypsum-based lightweight plastering material at least includes the following steps: first, the mixture is pre-prepared by weight, and then the gypsum powder, alkaline agent, water-retaining Add the agent, mixture and retarder into the mixer and stir evenly, then add vitrified microbeads and mix well, then enter the finished product warehouse.

Embodiment 1

[0057] Embodiment 1 of the present invention provides a gypsum-based lightweight plastering material. In parts by weight, the preparation raw materials include: 90 parts of gypsum powder, 1 part of alkaline agent, 0.15 part of water-retaining agent, 0.2 part of mixture, 0.1 part of Retarder, 11 parts vitrified microspheres.

[0058] The gypsum powder is β-semi-hydrated building gypsum; the preparation steps of the β-semi-hydrated building gypsum are: the desulfurized gypsum obtained by the wet desulfurization process of a thermal power plant is passed through a vibrating screen to remove larger pieces of gypsum and its impurities, and sent to Enter the indirect steam rotary kiln. The indirect steam rotary kiln uses 1.8MPa saturated steam as the heat source, and transfers the heat of the steam to the desulfurization gypsum through the indirect heat transfer method. After the desulfurization gypsum absorbs the heat, the temperature rises. free water; when the calcination tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com