Metallurgy heating furnace rapid fettling equipment adopting structural pressurized crushing for exhausting and bubble preventing

A technology of anti-bubble and heating furnace, which is applied in the field of metallurgy, can solve the problems of increasing working strength, injecting air into water glass, affecting fixed sizing work, etc., and achieves the effect of preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

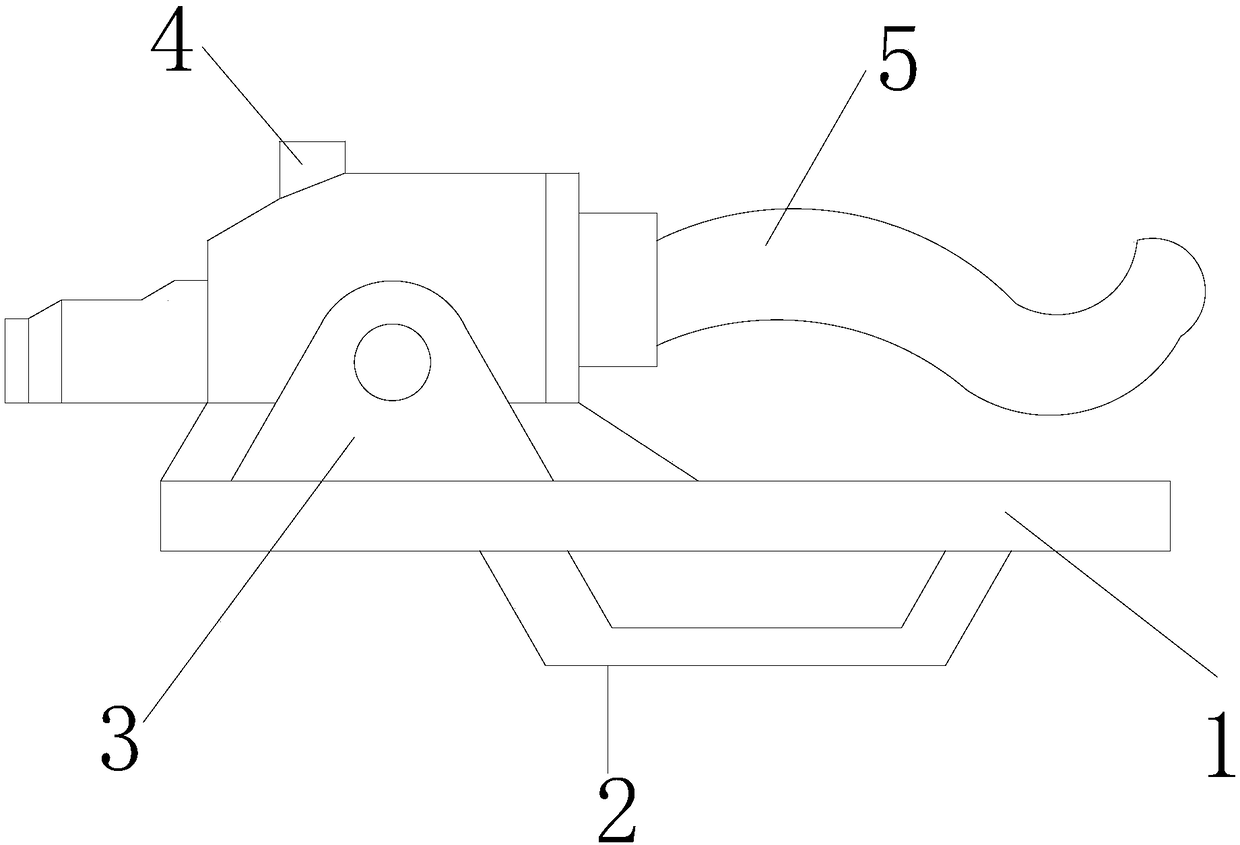

[0027] see figure 1 , the present invention provides rapid repairing equipment for metallurgical heating furnaces through structural pressurization, crushing, exhaust, and anti-bubble. The conveying pipe 5 is located at the right side end face of the intelligent feeding device 4 and embedded in the inside of the intelligent feeding device 4, the hinged seat 3 is arranged on the outer end face of the intelligent feeding device 4, and the two adopt clearance fit, and the mounting plate 1 is located on the lower end surface of the hinge seat 3 and is fixedly connected with the hinge seat 3. The handle frame 2 is perpendicular to the mounting plate 1 and is an integrated structure with the mounting plate 1. The inner side of the hinge seat 3 The end face is provided with a movable shaft rod frame, and the angle adjustment of the equipment can be performed through the external movable shaft rod frame.

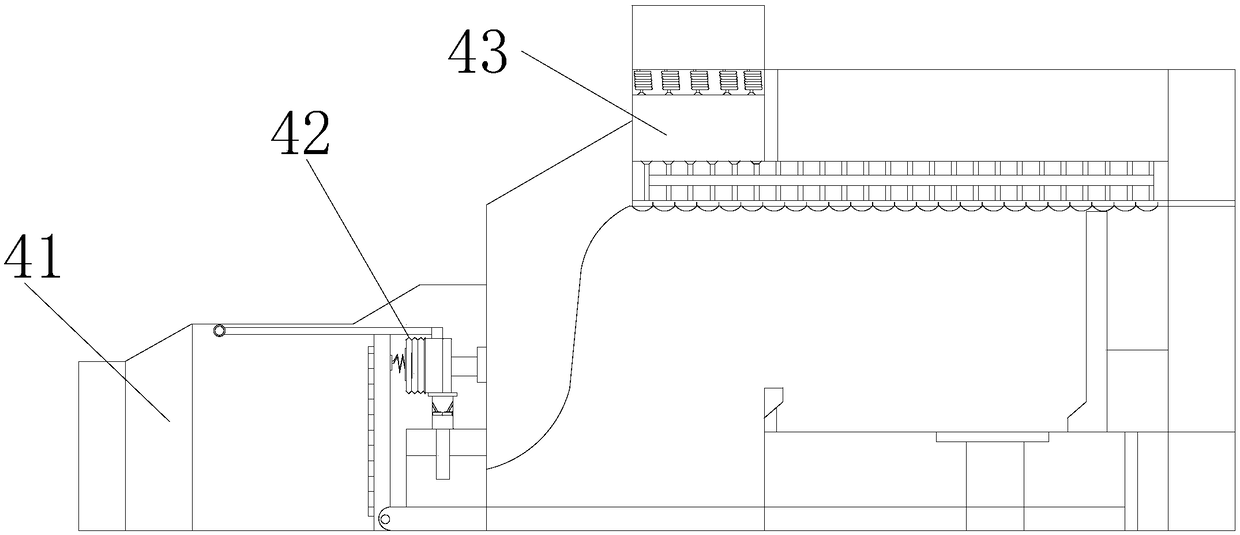

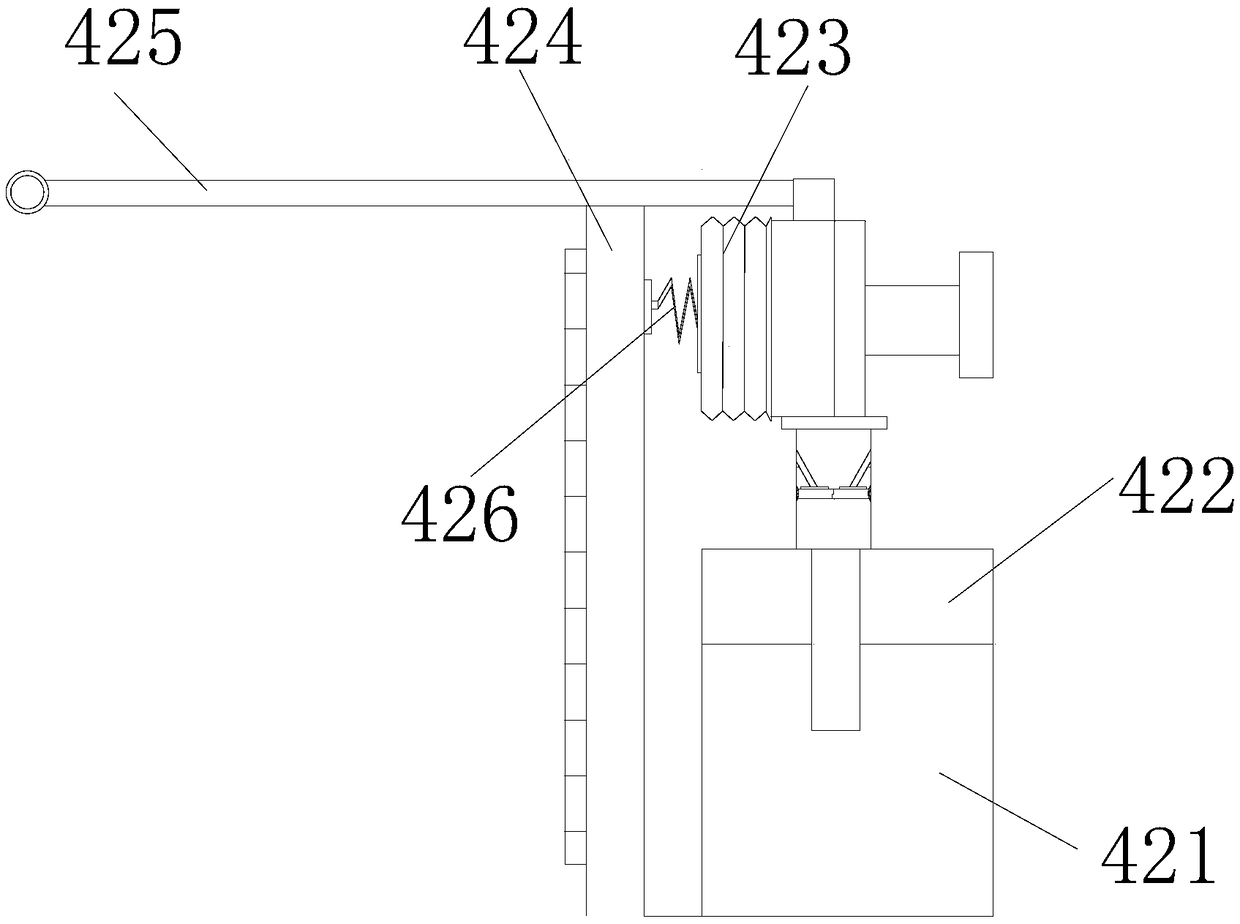

[0028] see figure 2, the present invention provides rapid repairing equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com