Preparation method of comfortable seersucker

A seersucker and comfortable technology, applied in the field of textile yarns, can solve the problems of destroying the comfort of wearing, and achieve the effect of stable twisting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of comfortable type seersucker, its process is as follows:

[0033] (1) Preparation of polyamide silk:

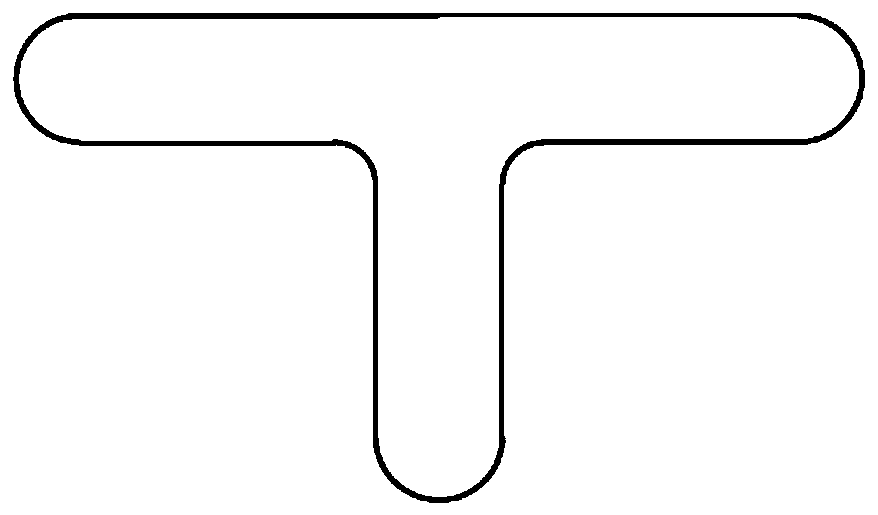

[0034] It is prepared from high viscosity polyamide 6 (intrinsic viscosity 2.5dL / g) and low viscosity polyamide 6 (intrinsic viscosity 2.22dL / g) with a mass ratio of 50:50 according to the FDY process and the process of round sheath-core composite fiber Polyamide filaments, wherein the spinneret holes on the spinneret are changed from circular to trilobal, all trilobal spinneret holes are T-shaped holes, and the three-lobal centerline of the same trilobal spinneret hole The ratio of the included angle is 1.0:1.0:2.0, the length and width of the three leaves are the same and the ratio of the length to the width is 3.1:1; the shape and size of the three leaves of different three-leaf spinneret holes are the same;

[0035] Use ring blowing to cool, and control the arrangement of the three-lobed spinneret holes on the spinneret: all the thre...

Embodiment 2

[0041] A kind of preparation method of comfortable type seersucker, its process is as follows:

[0042] (1) Preparation of polyamide silk:

[0043] It is prepared from high viscosity polyamide 6 (intrinsic viscosity 2.59dL / g) and low viscosity polyamide 6 (intrinsic viscosity 2.23dL / g) with a mass ratio of 50:50 according to the FDY process and the process of round sheath-core composite fiber Polyamide filaments, wherein the spinneret holes on the spinneret are changed from circular to trilobal, all trilobal spinneret holes are T-shaped holes, and the three-lobal centerline of the same trilobal spinneret hole The ratio of the included angle is 1.0:1.0:2.0, the length and width of the three leaves are the same and the ratio of the length to the width is 3.5:1; the shape and size of the three leaves of different three-leaf spinneret holes are the same;

[0044] Use ring blowing to cool, and control the arrangement of the three-lobed spinneret holes on the spinneret: all the thr...

Embodiment 3

[0050] A kind of preparation method of comfortable type seersucker, its process is as follows:

[0051] (1) Preparation of polyamide silk:

[0052] It is prepared from high viscosity polyamide 6 (intrinsic viscosity 2.6dL / g) and low viscosity polyamide 6 (intrinsic viscosity 2.24dL / g) with a mass ratio of 50:50 according to the FDY process and the process of round sheath-core composite fiber Polyamide filaments, wherein the spinneret holes on the spinneret are changed from circular to trilobal, all trilobal spinneret holes are T-shaped holes, and the three-lobal centerline of the same trilobal spinneret hole The ratio of the included angle is 1.0:1.0:2.0, the length and width of the three leaves are the same and the ratio of the length to the width is 2.5:1; the shape and size of the three leaves of different three-leaf spinneret holes are the same;

[0053] Use ring blowing to cool, and control the arrangement of the three-lobed spinneret holes on the spinneret: all the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com