Method for producing casein through dry sterilization

A technology of casein and dry method, which is applied in the preparation method of peptides, chemical instruments and methods, animal/human peptides, etc., to achieve the effect of improving the level of automation control, simple equipment, saving water, electricity and human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

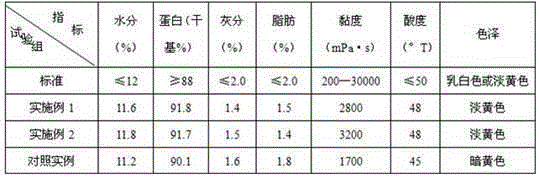

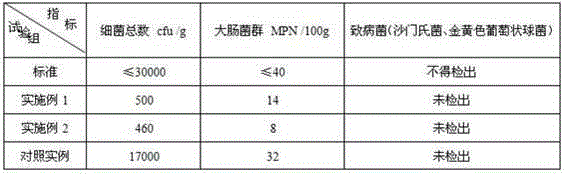

Examples

Embodiment 1

[0020] 1. Test material

[0021] Raw and auxiliary materials: 70 mesh Qula (3000Kg), auxiliary materials, hydrochloric acid (37%), sodium hydroxide (food grade caustic soda), water.

[0022] 2. A method for producing casein by dry sterilization, specifically comprising the following steps,

[0023] Dissolution: Put 200kg of koji into a 2-ton dissolution tank, add auxiliary materials, and dissolve for 50 minutes at a dissolution temperature of 55°C and a dissolution pH of 9.5-10.0.

[0024] Filtration: through double-layer gauze to remove impurities in the feed liquid.

[0025] Centrifugation: Centrifuge the filtrate to remove fat and impurities, and keep the feed temperature between 50 and 55°C.

[0026] Acid point: After degreasing, adjust the temperature of the feed liquid to 40°C, add hydrosulfite, sodium sulfite and sodium metabisulfite, use dilute hydrochloric acid with a Baume degree of 4.5 to precipitate casein, adjust the pH of the feed liquid to 4.4-4.6, and make th...

Embodiment 2

[0034] 1. Test material

[0035] Raw and auxiliary materials: 70 mesh Qula (5000Kg), auxiliary materials, hydrochloric acid (37%), sodium hydroxide (food grade caustic soda), water.

[0036] 2. A method for producing casein by dry sterilization, specifically comprising the following steps,

[0037] Dissolution: Put 200kg of koji into a 2-ton dissolution tank, add auxiliary materials, and dissolve for 50 minutes at a dissolution temperature of 55°C and a dissolution pH of 9.5-10.0.

[0038] Filtration: through double-layer gauze to remove impurities in the feed liquid.

[0039] Centrifugation: Centrifuge the filtrate to remove fat and impurities, and keep the feed temperature between 50 and 55°C.

[0040] Acid point: After degreasing, adjust the temperature of the feed liquid to 40°C, add hydrosulfite, sodium sulfite and sodium metabisulfite, use dilute hydrochloric acid with a Baume degree of 4.5 to precipitate casein, adjust the pH of the feed liquid to 4.4-4.6, and make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com