Method for preparing tung oil-modified water-based insulating paint

A technology of insulating paint and tung oil, applied in polyester coatings, coatings and other directions, can solve problems such as high cost, human health hazards, environmental pollution, etc., and achieve the effects of increasing added value, low cost, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

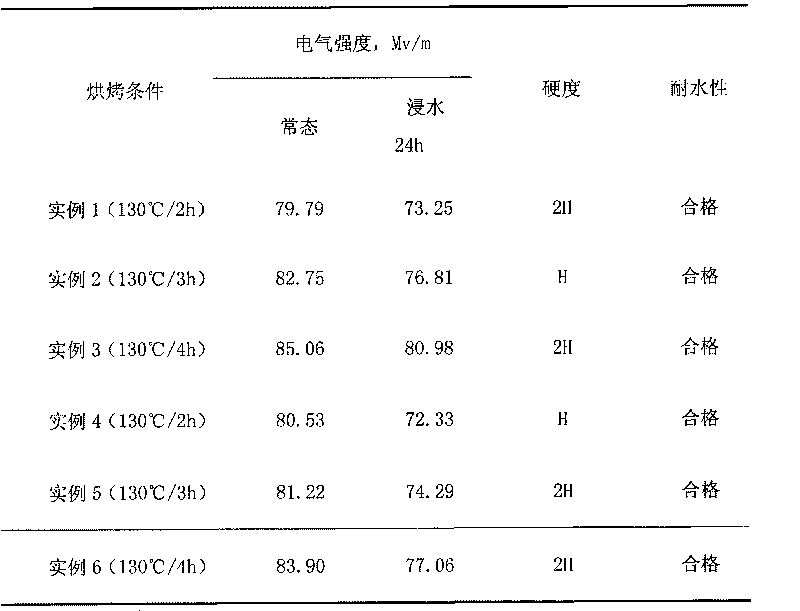

Examples

Embodiment 1

[0025] Add 45g trimethylolpropane, 13g glycerol, 18g adipic acid, 9g maleic anhydride, 3g Polyethylene Glycol-400 in the four-necked flask that stirrer, condenser and oil-water separator are housed, Protected by nitrogen, react at 200°C for 2h. Add 35g of phthalic anhydride and 22g of tung oil, and the reaction time at 200°C is about 4 hours. When the acid value reaches 55-65mgKOH / g, stop the reaction. Add 10g isopropanol, 10g propylene glycol methyl ether for dilution, add appropriate amount of N,N-dimethylethanolamine, N,N-dimethylethanolamine (N,N-dimethylethanolamine:N,N-diethylethanolamine= 1:1) to neutralize to pH=7.0-8.0 to obtain tung oil modified polyester resin liquid.

[0026] Mix tung oil-modified polyester resin liquid with etherified amino resin at a mass ratio of 85:15, add appropriate amount of dicumyl peroxide and di-tert-butyl peroxide, and prepare tung oil-modified water-based insulating varnish after 1 hour. Add water and stir so that the solid content of...

Embodiment 2

[0028] Add 45g trimethylolpropane, 13g glycerol, 25g azelaic acid, 9g maleic anhydride, 3g polyethylene glycol-400 in the four-necked flask that stirrer, condenser and oil-water separator are equipped with, Protected by nitrogen, react at 200°C for 2h. Add 35g of phthalic anhydride and 22g of tung oil, and the reaction time at 200°C is about 4 hours. When the acid value reaches 55-65mgKOH / g, stop the reaction. Add 10g isopropanol, 10g propylene glycol methyl ether for dilution, add appropriate amount of N,N-dimethylethanolamine, N,N-diethylethanolamine (N,N-dimethylethanolamine:N,N-diethylethanolamine= 1:1) to neutralize to pH=7.0-8.0 to obtain tung oil modified polyester resin liquid.

[0029] Mix tung oil modified polyester resin liquid with etherified amino resin at a mass ratio of 80:20, add appropriate amount of dicumyl peroxide and di-tert-butyl peroxide, and physically mix at room temperature for 0.5-1.0 hours to prepare tung oil modified Water-based insulating paint....

Embodiment 3

[0031] Add 45g trimethylolpropane, 13g glycerol, 15g malonic acid, 9g maleic anhydride, 3g polyethylene glycol-400 in the four-necked flask that stirrer, condenser and oil-water separator are housed, Protected by nitrogen, react at 200°C for 2h. Add 35g of phthalic anhydride and 22g of tung oil, and the reaction time at 200°C is about 4 hours. When the acid value reaches 55-65mgKOH / g, stop the reaction. Add 10g isopropanol, 10g propylene glycol methyl ether for dilution, add appropriate amount of N,N-dimethylethanolamine, N,N-diethylethanolamine (N,N-dimethylethanolamine:N,N-diethylethanolamine= 1:1) to neutralize to pH=7.0-8.0 to obtain tung oil modified polyester resin liquid.

[0032] Mix tung oil-modified polyester resin liquid with etherified amino resin at a mass ratio of 75:25, add dicumyl peroxide and di-tert-butyl peroxide, and physically mix at room temperature for 0.5-1.0 hours to prepare tung oil-modified For water-based insulating paint, add water and stir, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com