Adjustable high voltage capacitor device

A high-voltage capacitor, adjustable technology, applied in the direction of multi-connected capacitors, etc., can solve the problems that the coupling capacitor cannot be continuously adjusted, the resonance quality factor is low, etc., and achieve the effect of easy transportation and on-site assembly, good mechanical strength and electrical insulation strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention is an adjustable high-voltage capacitor device, which is a bracket that can hang high-voltage capacitors. The dielectric strength can reach 300kV.

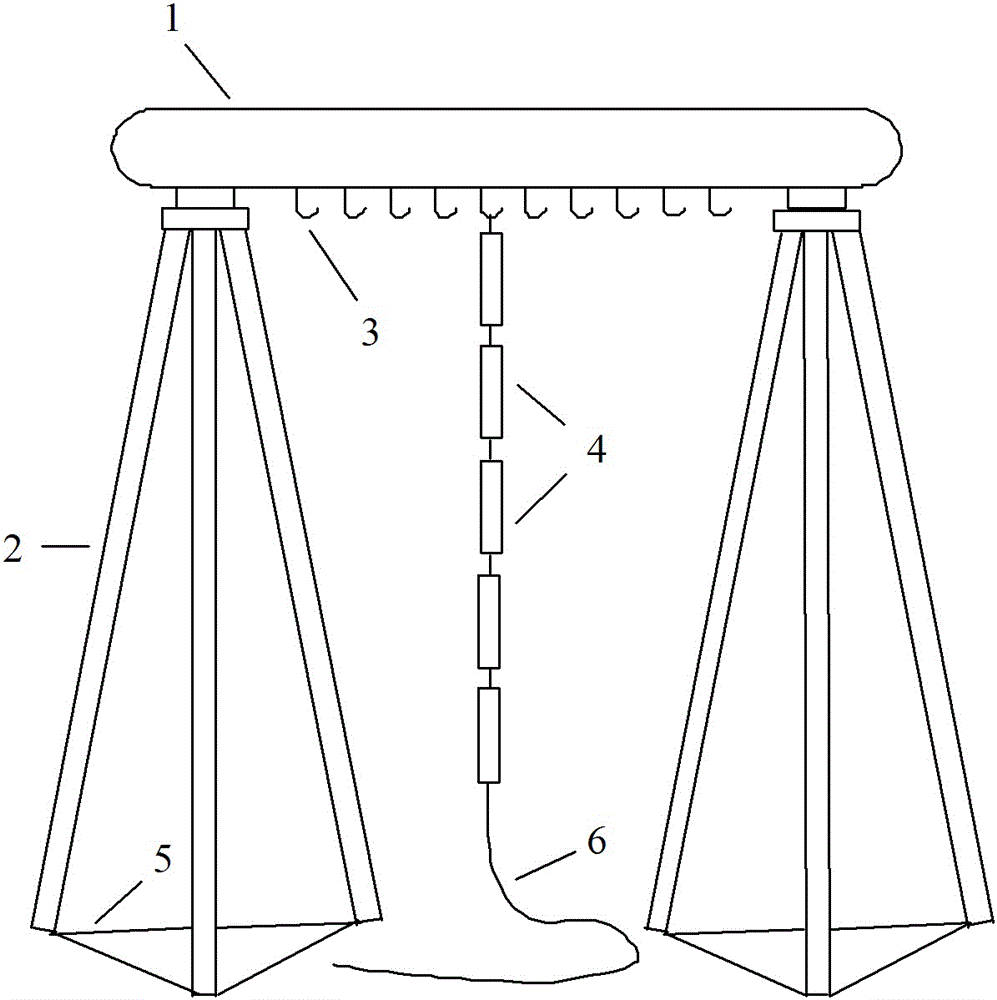

[0022] Such as figure 1 As shown, the present invention is connected with the insulating tripod 2 by the voltage equalizing conductive rod 1, and the insulating tripod 2 is provided with two, respectively connected to the two ends of the voltage equalizing conductive rod 1; There is a hook 3, and the hook 3 is connected with the high-voltage capacitor 4. Wherein the voltage equalizing conductive rod 1 is connected with the insulating tripod 2 by a screw, one end of the screw is welded on the voltage equalizing conductive rod 1, the other end is connected on the insulating tripod 2, and is locked with a nut. Ten hooks 3 are welded on the equalizing conductive rod 1 for hanging high-voltage capacitors 4, and the feet of the insulating tripod 2 are connected by iron chains 5 to reinforce and support the...

Embodiment 2

[0031] During specific implementation, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 ... several Hook 3. A string of high-voltage capacitors 4 can be connected to each hook 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com