Novel photovoltaic assembly structure

A photovoltaic module, a new type of technology, applied in the direction of photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of thick anodic oxidation layer, increase the cost of the backplane, and cannot be promoted and applied in the market, so as to achieve good heat dissipation effect and improve Effects of dielectric strength and excellent ultraviolet absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

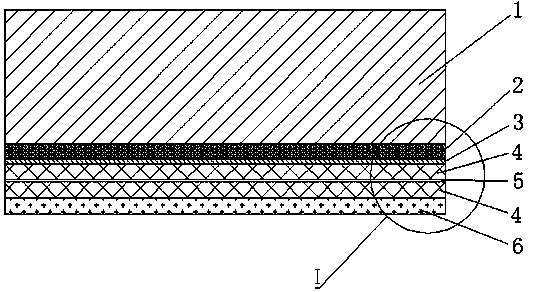

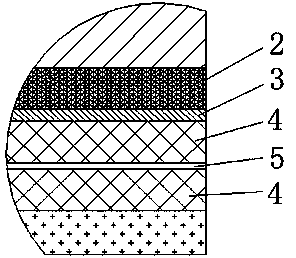

[0016] Such as figure 1 , figure 2 As shown, the photovoltaic module structure of the architectural photovoltaic component of the present invention includes a surface glass 1, a solar cell 3 and a back plate 6 from top to bottom, the surface glass 1 and the solar cell 3 are connected by a PVB film 2, and the back plate 6. The material is a metal plate. An insulating film layer 5 is provided between the solar cell 3 and the back plate 6. The solar cell 3 and the insulating film layer 5 are connected through the EVA film 4. The insulating film layer 5 and the back plate 6 are connected through the EVA film. 4 are connected, and the insulating film layer 5 is a PET film. The photovoltaic module structure of the present invention adopts the EVA film with high bonding strength to sandwich the insulating film to strengthen the electrical insulation strength of the photovoltaic module, which can meet the insulation requirements of various types of backplane materials and solar cell...

Embodiment 2

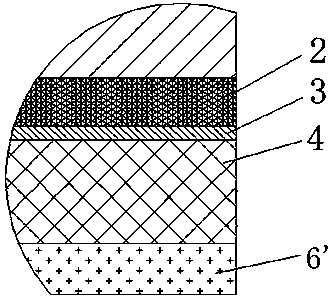

[0018] Such as image 3 As shown, the photovoltaic module structure of the architectural photovoltaic component of the present invention includes a surface glass 1, a solar cell 3 and a back plate 6' from top to bottom, and the surface glass 1 and the solar cell 3 are connected by a PVB film 2, and the back The material of the board 6' is polyimide, polycarbonate, polyvinyl fluoride, polyethylene terephthalate or polypropylene film with good insulation performance, and the solar cell sheet 3 and the back board 6' pass through EVA film 4 is connected. Composite materials have excellent ultraviolet absorption due to PVB, which can effectively protect materials such as EVA. The photovoltaic module of the building photovoltaic component of the present invention has excellent insulation performance, good heat dissipation effect and low manufacturing cost, which improves the structural strength of the photovoltaic module, and also solves the problems of difficult bonding of related...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com