Aqueous tung oil-based insulating paint and preparation method thereof

A technology of insulating varnish and tung oil, applied in the direction of fatty acid production, fatty acid esterification, coating, etc., to achieve good film-forming properties, good comprehensive performance, and high electrical insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

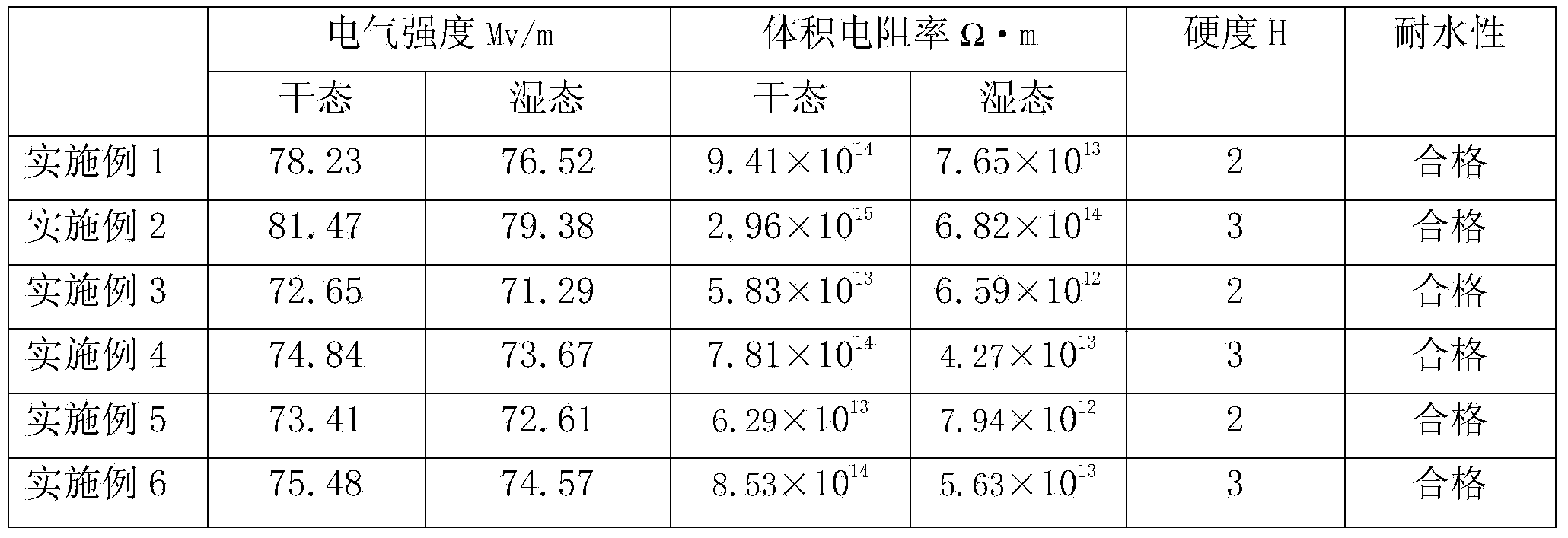

Examples

Embodiment 1

[0032] 1. Add 60g of tung oil and 18g of maleic anhydride into the reactor, under nitrogen protection, condense and reflux at 140°C for 1.5h, and cool down to 110°C after the reaction to obtain addition-modified tung oil;

[0033] 2. Add 10g of isopropanol and 10g of propylene glycol methyl ether to the resin solution prepared in step 1, and then add 48g of polyethylene glycol (PEG-1000) under the protection of nitrogen, and react at this temperature for 2h to obtain esterification modification Sexual tung oil;

[0034] 3. Stir and dissolve 21g of epoxy resin (E-51) with 10g of n-butanol and 15g of ethylene glycol butyl ether at 60°C for 30 minutes, cool down the resin solution prepared in step 2 to 90°C, and then dissolve the dissolved ring Oxygen resin was slowly added dropwise to the above resin liquid, and catalyst triethylamine 0.21g was added, reacted at 90°C for 2.5h, cooled to room temperature after the reaction, and epoxy-modified tung oil was obtained;

[0035] 4. A...

Embodiment 2

[0039] 1. Add 60g of tung oil and 18g of maleic anhydride into the reactor, under nitrogen protection, condense and reflux at 140°C for 1.5h, and cool down to 110°C after the reaction to obtain addition-modified tung oil;

[0040] 2. Add 10g of isopropanol and 10g of propylene glycol methyl ether to the resin solution prepared in step 1, and then add 48g of polyethylene glycol (PEG-1000) under the protection of nitrogen, and react at this temperature for 2h to obtain esterification modification Sexual tung oil;

[0041] 3. Stir and dissolve 21g of epoxy resin (E-51) with 10g of n-butanol and 15g of ethylene glycol butyl ether at 60°C for 30 minutes, cool down the resin solution prepared in step 2 to 90°C, and then dissolve the dissolved ring Oxygen resin was slowly added dropwise to the above resin liquid, and catalyst triethylamine 0.21g was added, reacted at 90°C for 2.5h, cooled to room temperature after the reaction, and epoxy-modified tung oil was obtained;

[0042] 4. A...

Embodiment 3

[0046] 1. Add 60g of tung oil and 18g of maleic anhydride into the reactor, under nitrogen protection, condense and reflux at 140°C for 1.5h, and cool down to 110°C after the reaction to obtain addition-modified tung oil;

[0047] 2. Add 10g of isopropanol and 10g of propylene glycol methyl ether to the resin solution prepared in step 1, and then add 48g of polyethylene glycol (PEG-1000) under the protection of nitrogen, and react at this temperature for 2h to obtain esterification modification Sexual tung oil;

[0048] 3. Stir and dissolve 21g of epoxy resin (E-51) with 10g of n-butanol and 15g of ethylene glycol butyl ether at 60°C for 30 minutes, cool down the resin solution prepared in step 2 to 90°C, and then dissolve the dissolved resin Slowly add dropwise to the above resin liquid, and add catalyst triethylamine 0.21g, react at 90°C for 2.5h, cool to room temperature after the reaction, and obtain epoxy-modified tung oil;

[0049] 4. Add 15g of isopropanol and 15g of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com