Pouring technology for all-fiber optical current transformer

A current transformer, all-fiber technology, applied in the field of all-fiber current transformer casting technology, to achieve the effect of improving product yield, excellent electrical insulation performance, dimensional stability and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

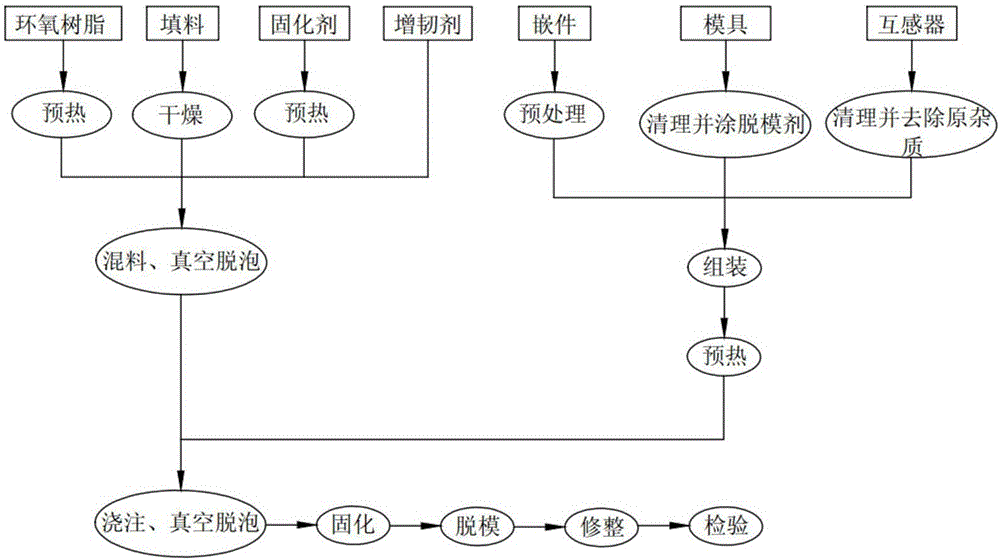

[0042] Such as figure 1 As shown, the all-fiber optic current transformer casting process of this embodiment, because epoxy resin has excellent electrical insulation properties, high mechanical strength, heat resistance, chemical corrosion resistance, good curing shrinkage and linear expansion coefficient, dimensional stability and Good workmanship, therefore, it is mainly used in electrical products such as transformers, transformers, insulators, etc., and its voltage level range has been developed from 10kV and below to 35kV.

[0043] In the existing manufacturing process of various all-fiber current transformers, the working temperature is -40°C-+70°C, but during the epoxy casting process, the curing temperature can reach 120°C, which will affect its performance or even damage the full-fiber current transformer. Transformer.

[0044] This embodiment adopts the mainstream full vacuum pouring process. The advantage is that the whole process of batching, mixing and pouring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com