Composite insulated metallic oxide arrester

A technology of composite insulation and lightning arrester, applied in the direction of overvoltage protection resistors, varistors, etc., can solve the problems of electrical aging and thermal damage of resistor sheets, achieve enhanced electrical insulation strength, avoid freewheeling arcs, avoid electrical aging and The effect of thermal damage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

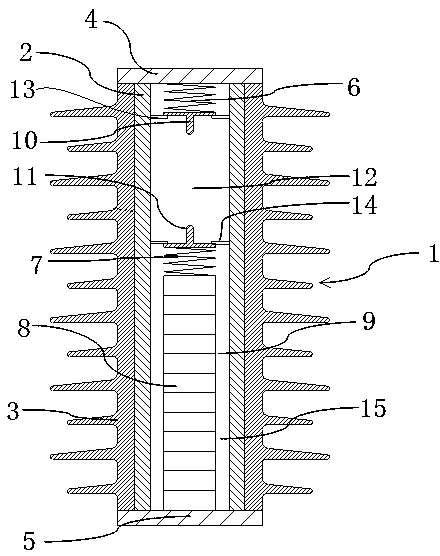

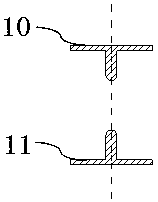

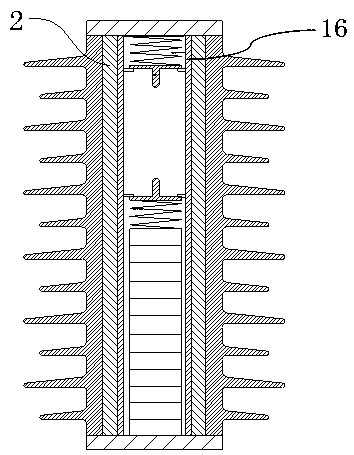

[0028] Such as figure 1 As shown, a composite insulated metal oxide lightning arrester, the lightning arrester 1 includes a hollow insulating tube 2, an umbrella group cover 3 coated on the outer wall of the hollow insulating tube 2, and first metal tubes respectively arranged at the upper and lower ends of the hollow insulating tube 2. The end plate 4 and the second metal end plate 5 also include a first metal elastic body 6 axially arranged in the hollow insulating tube 2 from top to bottom, a discharge gap structure, a second metal elastic body 7 and at least two stacked The zinc oxide resistance sheet 8, the first metal elastic body 6, the discharge gap structure, the second metal elastic body 7 and the zinc oxide resistance sheet 8 all form a gap 9 with the hollow insulating tube 2 in its radial direction, and the first The upper end of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com