Method for preparing metal fiber sintered felt by spark plasma sintering

A technology of discharge plasma and metal fiber felt, applied in the field of preparation of metal sintered fiber felt, to achieve high air permeability, controllable porosity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of the metal sintered felt of the present embodiment comprises the following steps:

[0025] Step 1. The raw material adopts a grammage of 300g / m 2 Stainless steel fiber felt, the fiber diameter is 20μm, the fiber length is 30mm, and the stainless steel fiber density is 8.00g / cm 3 .

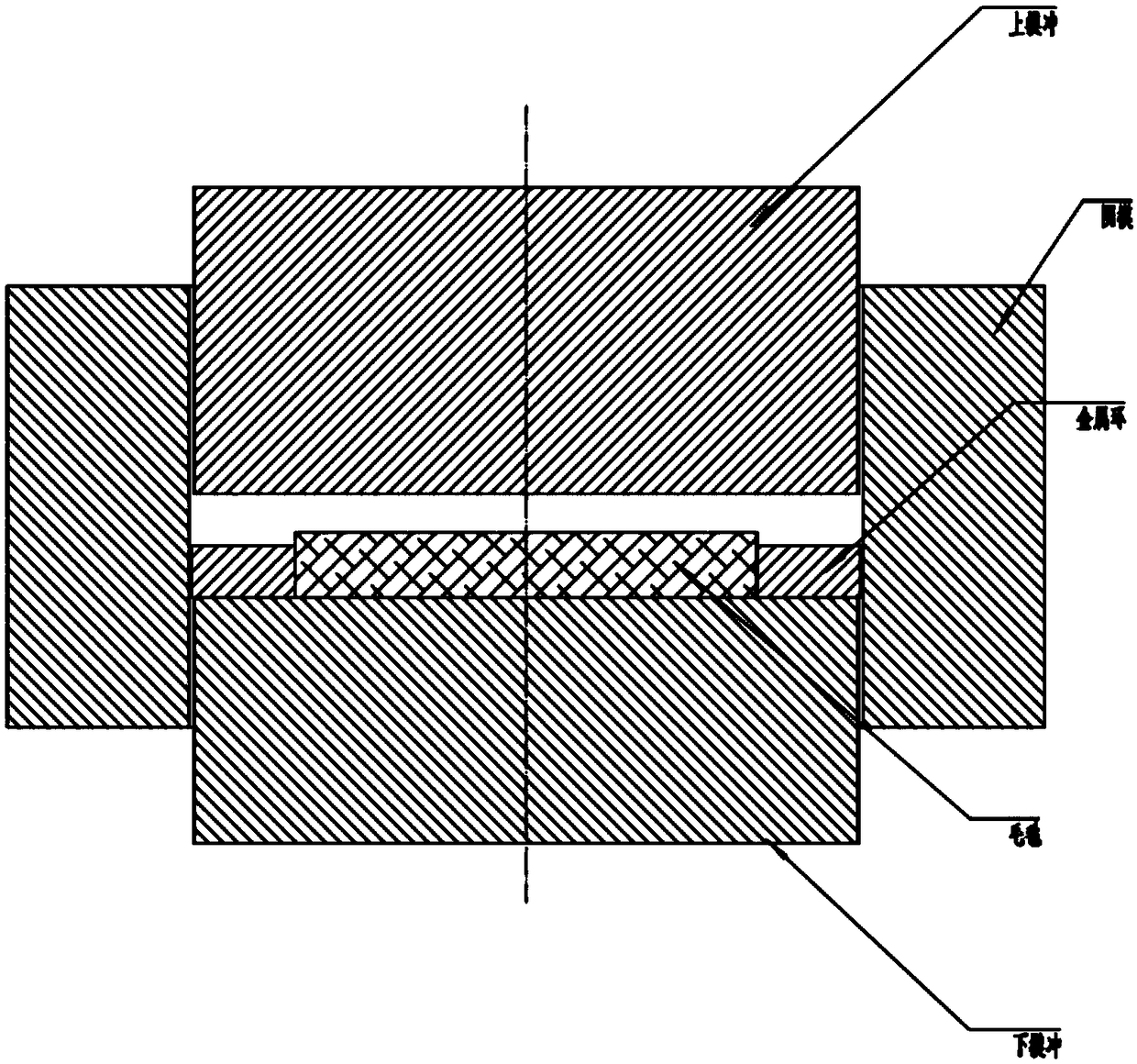

[0026] Step 2. Put the stainless steel fiber felt and 0.31mm thick stainless steel metal ring gasket in the step 1 into the graphite mold, and send them into the spark plasma sintering furnace together. The stacking thickness of the stainless steel fiber felt is 0.60-0.80 mm.

[0027] Step 3: Close the furnace, perform pre-pressurization treatment (pressure 2MPa), vacuumize, heat up to 1000°C at 100°C / min, keep warm for 10min, cool to room temperature after sintering, and take out the stainless steel fiber sintered felt.

[0028] The porosity of the stainless steel fiber mat prepared in this example is 88%, the air permeability is basically the same as that of th...

Embodiment 2

[0030] Other conditions are the same as in Example 1, except that carbon paper is placed on the contact surface of the upper die, lower die, and metal ring with the metal felt to be sintered or on the contact surface.

[0031] The porosity of the stainless steel fiber mat prepared in this example is 90%, and the air permeability value and the maximum tensile force value are basically the same as those obtained in Example 1.

[0032] Repeat embodiment 1 and embodiment 2 each 500 times; embodiment 2 does not need to be replaced in the repeating process, and product quality is stable; To use, only replace the mold. Simultaneously embodiment 1 is in the process of repeating 150 times, and the number of times that metal felt is bonded on the mold is 5 times; But embodiment 2 does not have this phenomenon.

Embodiment 3

[0034] The preparation process of the metal sintered felt of the present embodiment comprises the following steps:

[0035] Step 1, the raw material adopts a grammage of 450g / m 2 Fe-Cr-Al fiber felt with a fiber diameter of 30 μm, a fiber length of 30 mm, and a Fe-Cr-Al fiber density of 7.20 g / cm 3 .

[0036] Step 2. Put the iron-chromium-aluminum fiber felt in step 1 and the 0.63mm stainless steel metal ring gasket into the graphite mold together, and send them into the spark plasma sintering furnace together. The stack thickness of the stainless steel fiber felt is 1.00-1.20mm.

[0037] Step 3: Close the furnace, perform pre-pressurization treatment (pressure is 2MPa), vacuumize, heat up to 1100°C at 100°C / min, keep warm for 8min, cool to room temperature after sintering, and take out the FeCrAl fiber sintered felt.

[0038] The porosity of the Fe-Cr-Al fiber felt prepared in this example is 90%, the air permeability is basically the same as that of the vacuum sintered pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com