Composite material stripline antenna processing method

A technology of composite materials and processing methods, which is applied to the structural form of antennas, electrical components, and radiation elements, to achieve the effects of reducing lifting power, reducing manufacturing costs, and good electrical performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

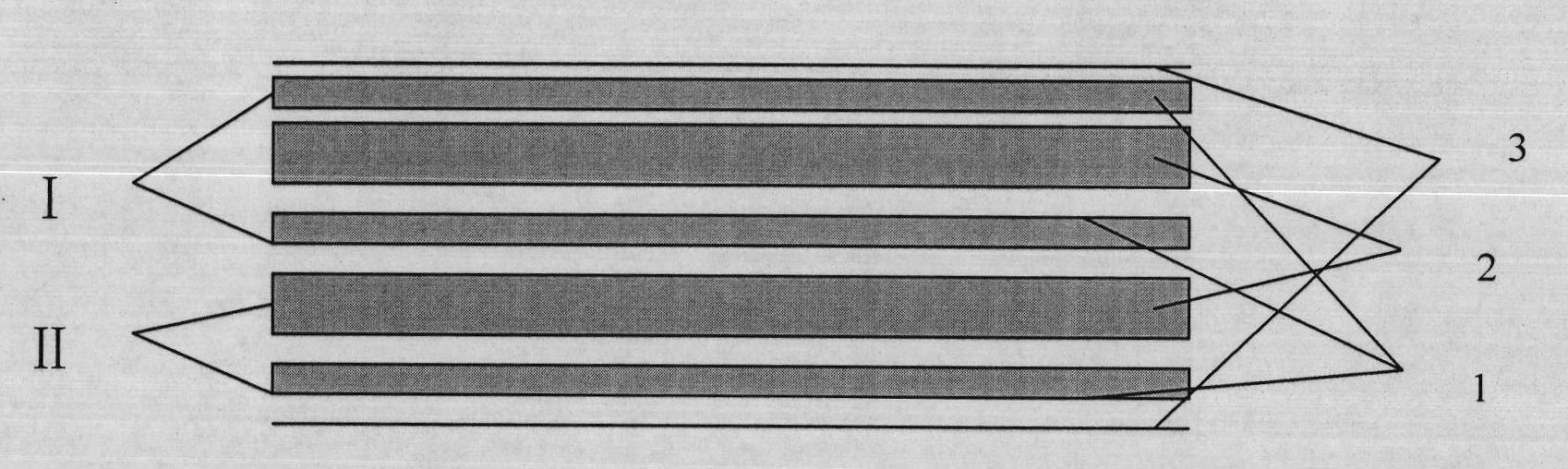

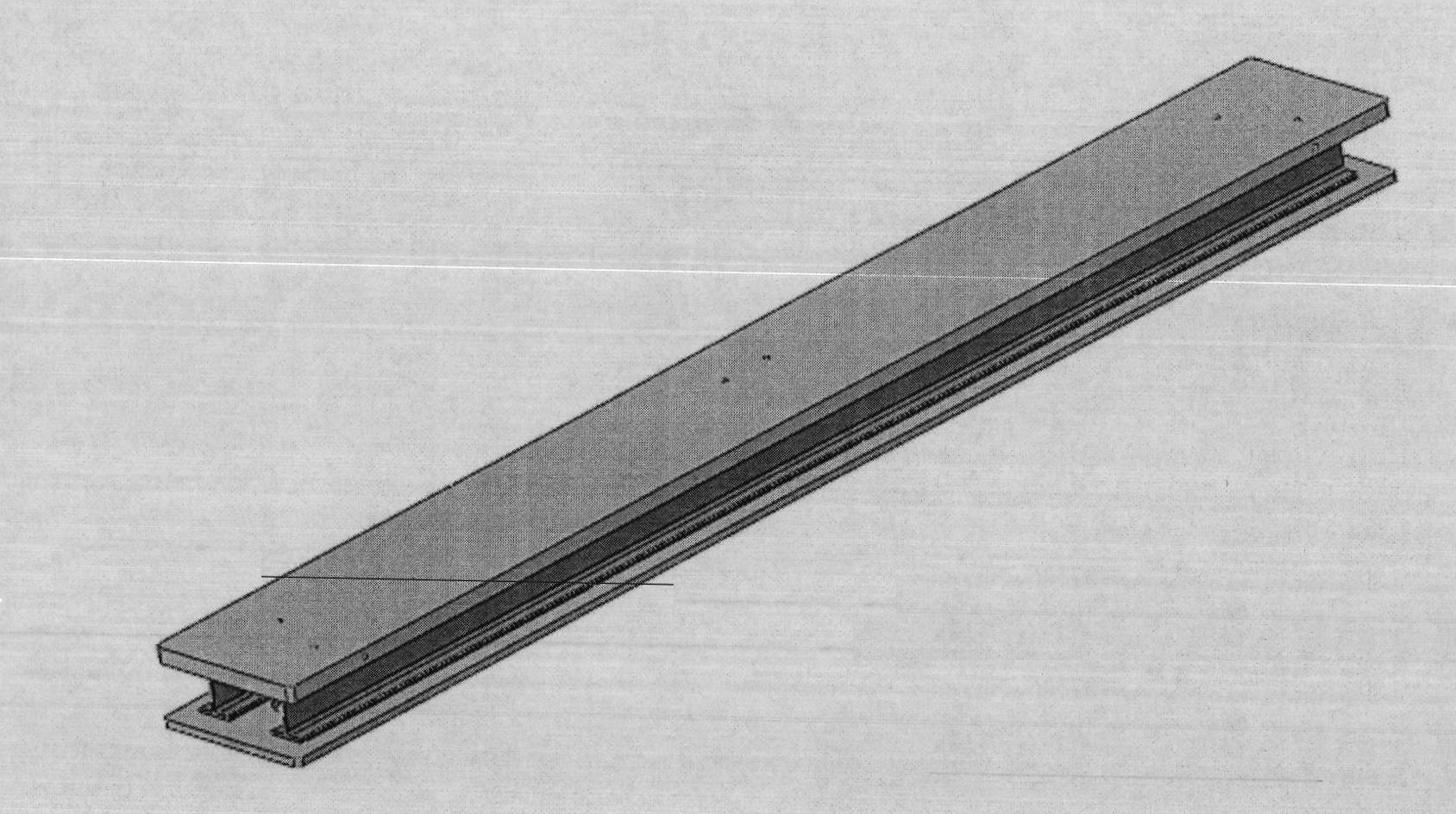

[0027] A certain radar antenna is taken as an example below to describe the specific implementation manner of the present invention. This type of antenna is a strip antenna made of composite material, which consists of 24 elements, each of which has a dimension of 2400mm×200mm×10mm, and consists of three layers of microstrip circuit board 1, two layers of core material 2, two layers of skin 3 and A total of 11 layers of six layers of adhesive film are laminated and bonded, such as figure 1 shown.

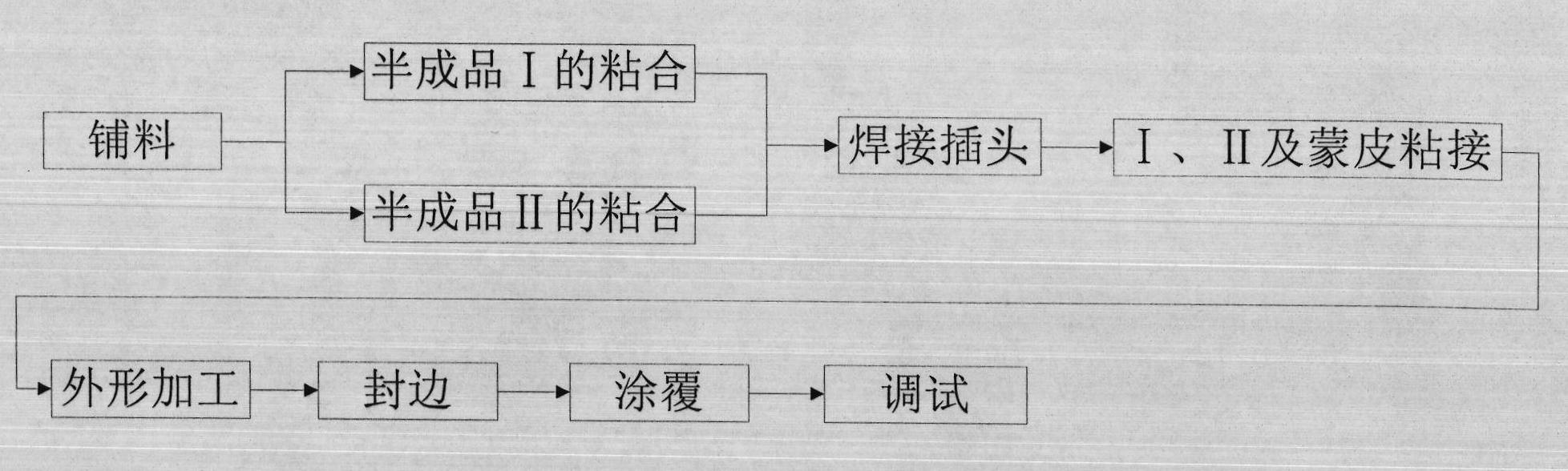

[0028] The processing of the antenna should be carried out as follows:

[0029] 1. Antenna material There are many structural materials for antennas, such as aluminum honeycomb, paper honeycomb, foam core material, etc. The resin systems used include polyester, epoxy, acrylic, etc. At present, commonly used materials cannot meet the performance requirements of the antenna. After repeated tests, comparisons and tests, the core material of the stripline antenna is selected from Swis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com