Preparation method of mould-proof clean type glass cement

A clean, glass glue technology, used in non-polymer adhesive additives, adhesive additives, polymer adhesive additives, etc. Fast, unclean and other problems, to avoid blackening and moldy, high elasticity, and reduce toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

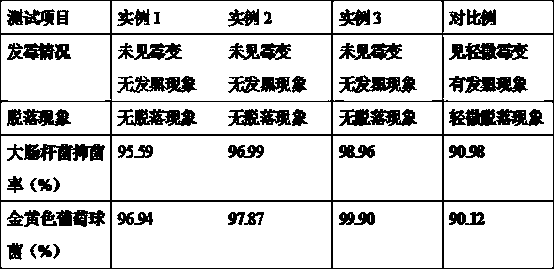

Examples

example 1

[0025]Take the washed water chestnut skin and place it in an oven, heat it up to 60°C, and dry it for 3 hours to obtain dried water chestnut skin. Weigh 200g of the dried water chestnut skin and put it into a water bath, add 300mL of water chestnut skin to the water bath with a mass fraction of 65 % ethanol solution, heated up to 50°C, soaked for 30 minutes, and softened water chestnut skin liquid was obtained; the softened water chestnut skin liquid was placed in an ultrasonic oscillator, and after oscillating at a frequency of 25KHz for 10 minutes, ultrasonically treated water chestnut skin was obtained. Put the water chestnut skin into an ethanol solution with a mass fraction of 65%, heat it up to 50°C, soak it for 25 minutes, put it in a Buchner funnel, filter under reduced pressure to obtain the water chestnut skin extract, put the water chestnut skin extract into the vacuum In the drying oven, set the drying temperature to 100°C and dry for 45min to obtain the dry extract...

example 2

[0027] Take the washed water chestnut skin and place it in an oven, heat it up to 65°C, and dry it for 4 hours to obtain dried water chestnut skin. Weigh 210g of dried water chestnut skin and put it into a water bath, add 315mL of water chestnut skin to the water bath with a mass fraction of 65 % ethanol solution, heated up to 52°C, soaked for 35 minutes, to obtain softened water chestnut skin liquid; put the softened water chestnut skin liquid in an ultrasonic oscillator, and vibrated at a frequency of 27KHz for 12 minutes to obtain ultrasonically treated water chestnut skin, and ultrasonically treated Put the water chestnut skin into an ethanol solution with a mass fraction of 65%, heat it up to 52°C, soak it for 27 minutes, put it in a Buchner funnel, filter under reduced pressure to obtain the water chestnut skin extract, put the water chestnut skin extract into the vacuum In the drying oven, set the drying temperature to 105°C, and dry for 50 minutes to obtain the dry extr...

example 3

[0029] Take the washed water chestnut skin and place it in an oven, heat up to 70°C, and dry for 5 hours to obtain dried water chestnut skin. Weigh 220 g of dried water chestnut skin and put it into a water bath, add 330 mL of water chestnut skin to the water bath with a mass fraction of 65 % ethanol solution, heated up to 55°C, soaked for 40 minutes, to obtain softened water chestnut skin liquid; put the softened water chestnut skin liquid in an ultrasonic oscillator, vibrate at a frequency of 30 KHz for 15 minutes, and obtain ultrasonically treated water chestnut skin, and ultrasonically The processed water chestnut skin is put into the ethanol solution with a mass fraction of 65%, and the temperature is raised to

[0030] After soaking at 55°C for 30 minutes, put it in a Buchner funnel, filter under reduced pressure to obtain the water chestnut skin extract, put the water chestnut skin extract into a vacuum drying oven, set the drying temperature to 110°C, and dry for 55 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com