Modified polyurethane adhesive, composite waterproof adhesive strip comprising modified polyurethane adhesive, and preparation method and application thereof

A polyurethane adhesive, polyurethane technology, applied in polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., can solve the problem of not widely adapting to windproof bonding strength, waterproof requirements, low cost requirements, breathable and moisture permeable materials Low strength, low bonding strength and other problems, to achieve good washing resistance and moisture permeability, good elasticity, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

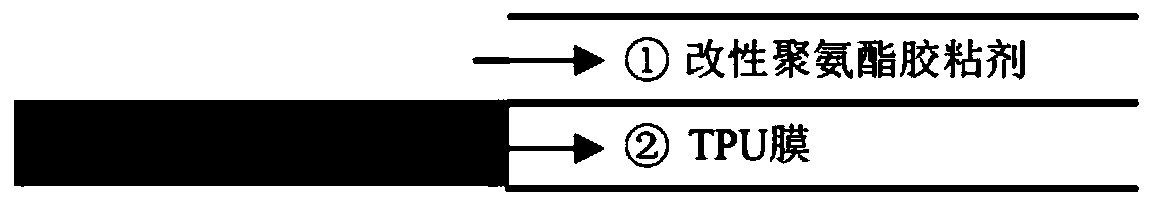

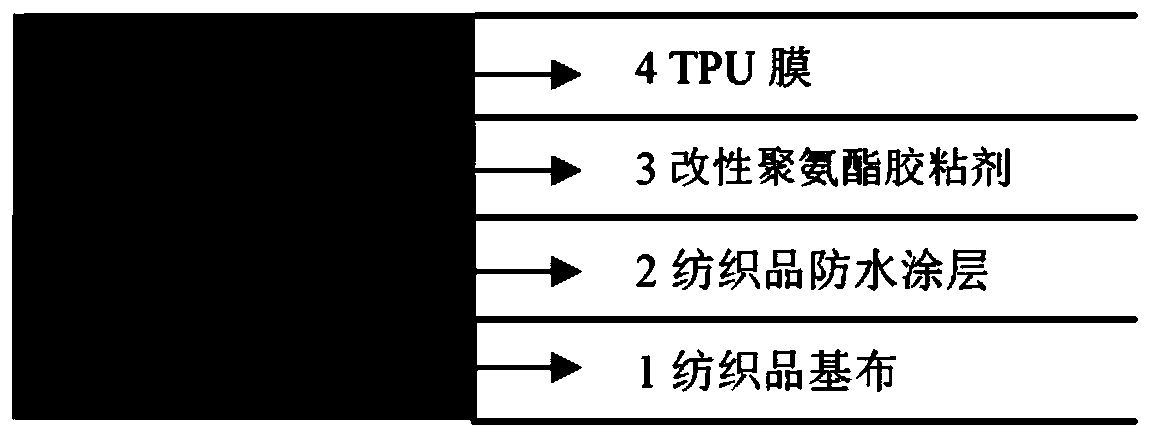

[0045] 40 parts of polyester polyurethane with hydroxyl group (melt mass flow rate is 15g / 10min, melt viscosity is 6000mPa·s), 60 parts of polyether polyurethane particles with carboxyl group (melt mass flow rate is 5g / 10min 10 minutes, melt viscosity is 10000mPa·s), 10 parts of PES particles (melt mass flow rate is 10g / 10 minutes, melt viscosity is 8000mPa·s), 2 parts of polycarbodiimide, 2 parts of phenolic sealant End-blocking isocyanate (unblocking temperature above 140°C), 0.3 parts of antioxidant 1010 and 1 part of coupling agent 3-aminopropyltriethoxysilane (KH-550) were mixed uniformly in a high-speed disperser in advance, and then The tape casting machine is extruded and cast into a 0.05mm thick modified polyurethane adhesive coated on a TPU film (polyester polyurethane, the melt mass flow rate is 5g / 10 minutes, the melt viscosity is 20000mPa s, and the thickness is 0.05 mm, water pressure resistance greater than 10000mmH 2 (0 / 2min) is thermally compounded to make a co...

Embodiment 2

[0047] 35 parts of polyester polyurethane particles with hydroxyl groups (melt mass flow rate is 20g / 10min, melt viscosity is 10000mPa·s), 65 parts of polyether polyurethane particles with amino groups (melt mass flow rate is 10g / 10min, melt viscosity is 15000mPa·s), 8 parts of PES particles (melt mass flow rate is 15g / 10min, melt viscosity is 10000mPa·s), 3 parts of polycarbodiimide, 2 parts of amide sealant Blocked isocyanate (unblocking temperature above 150°C), 0.2 parts of antioxidant 1076, 1 part of coupling agent 3-aminopropyltriethoxysilane (KH-550) and 1 part of coupling agent γ-aminoethyl Aminopropyltrimethoxysilane (KH-792) is pre-mixed uniformly in a high-speed disperser, extruded and cast into a 0.05mm thick modified polyurethane adhesive coated on a TPU film (polyether polyurethane , the melt mass flow rate is 10g / 10min, the melt viscosity is 15000mPa·s, the thickness is 0.05mm, and the water pressure resistance is greater than 10000mmH 2 (0 / 2min) is thermally ...

Embodiment 3

[0049] 20 parts of polyester polyurethane particles with hydroxyl group (melt mass flow rate is 20g / 10min, melt viscosity is 15000mPa·s), 20 parts of polyether polyurethane particles with carboxyl group (melt mass flow rate is 15g / 10 minutes, melt viscosity is 8000mPa s), 70 parts of polyether polyurethane particles with amino groups (melt mass flow rate is 15g / 10 minutes, melt viscosity is 18000mPa s), 12 parts of PES particles (melt Body mass flow rate of 30g / 10min, melt viscosity of 8000mPa s), 2.5 parts of polycarbodiimide, 4 parts of phenolic blocked isocyanate (unblocking temperature above 140°C), 0.2 parts of antioxidant 1076, 0.1 part of antioxidant 1010, 1 part of coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) and 1.5 parts of hydroxysilane oligomer (6650) are pre-mixed in a high-speed disperser , extruded and casted into a 0.05mm thick modified polyurethane adhesive coated on TPU film (polyester polyurethane, melt mass flow rate is 10g / 10min, mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com